Radiation transducer and method to produce a radiation transducer

a radiation transducer and transducer technology, applied in the direction of conversion screens, fluorescence/phosphorescence, optical radiation measurement, etc., can solve the problems of described light yield impairment and light yield impairment, and achieve the effect of higher light yield and light yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

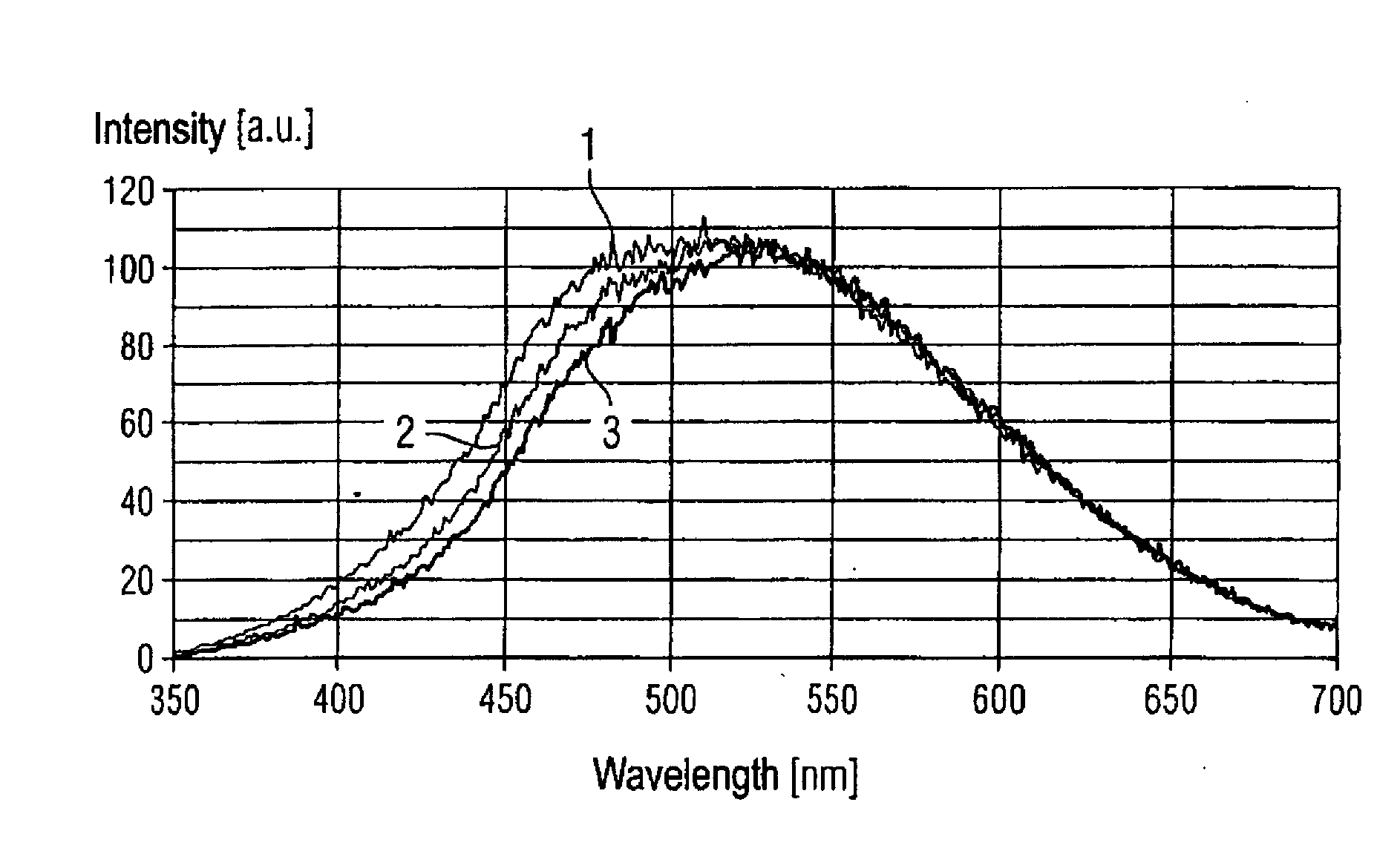

[0015]In the radiation transducer according to the invention, the oxidation state of the luminophore layer (scintillator layer) is fixed by the application of the anti-discoloration substance before the additional processing, which essentially forms an encapsulation (packaging) of the scintillator layer. A yellowing of the luminophore layer in the packaging process is very significantly reduced or even entirely prevented. This causes the light yield of the luminophore layer in the radiation transducer according to the invention to be thus significantly higher, by approximately 10 to 15%.

[0016]An additional yellowing during the lifespan of the radiation transducer due to environmental influences (moisture temperature) is also significantly reduced or even entirely prevented by the anti-discoloration substance.

[0017]In an embodiment the inventive method, the oxidation state of the luminophore layer (scintillator layer) is fixed via the application of at least one anti-discoloration su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thicknesses | aaaaa | aaaaa |

| humidity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com