Multifunctional fuel gas nozzle

a multi-functional, fuel gas technology, applied in the direction of burners, combustion types, combustion processes, etc., can solve the problems of difficult to distinguish the difference between the diameters of the nozzles, the nozzle cannot be changed by consumers, and the nozzle diameter is difficult to be easily adjusted by consumers, so as to simplify the nozzle structure, facilitate and rapid adjustment of the nozzle diameter, the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

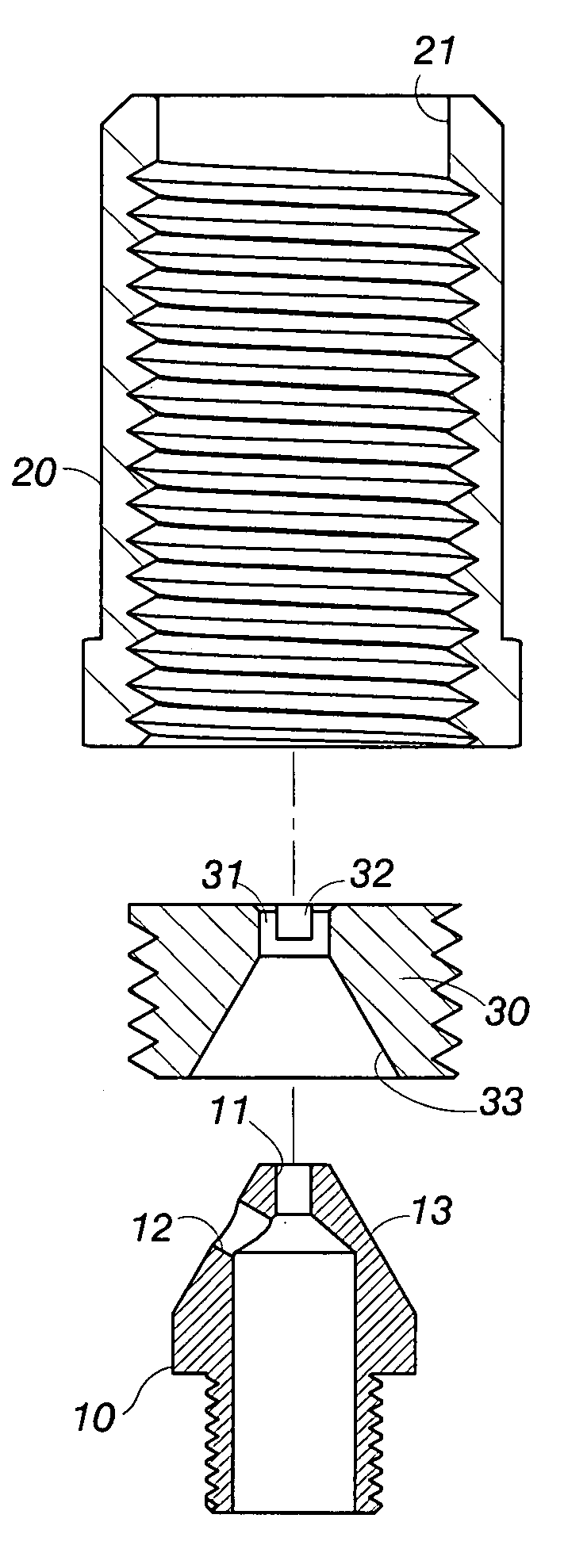

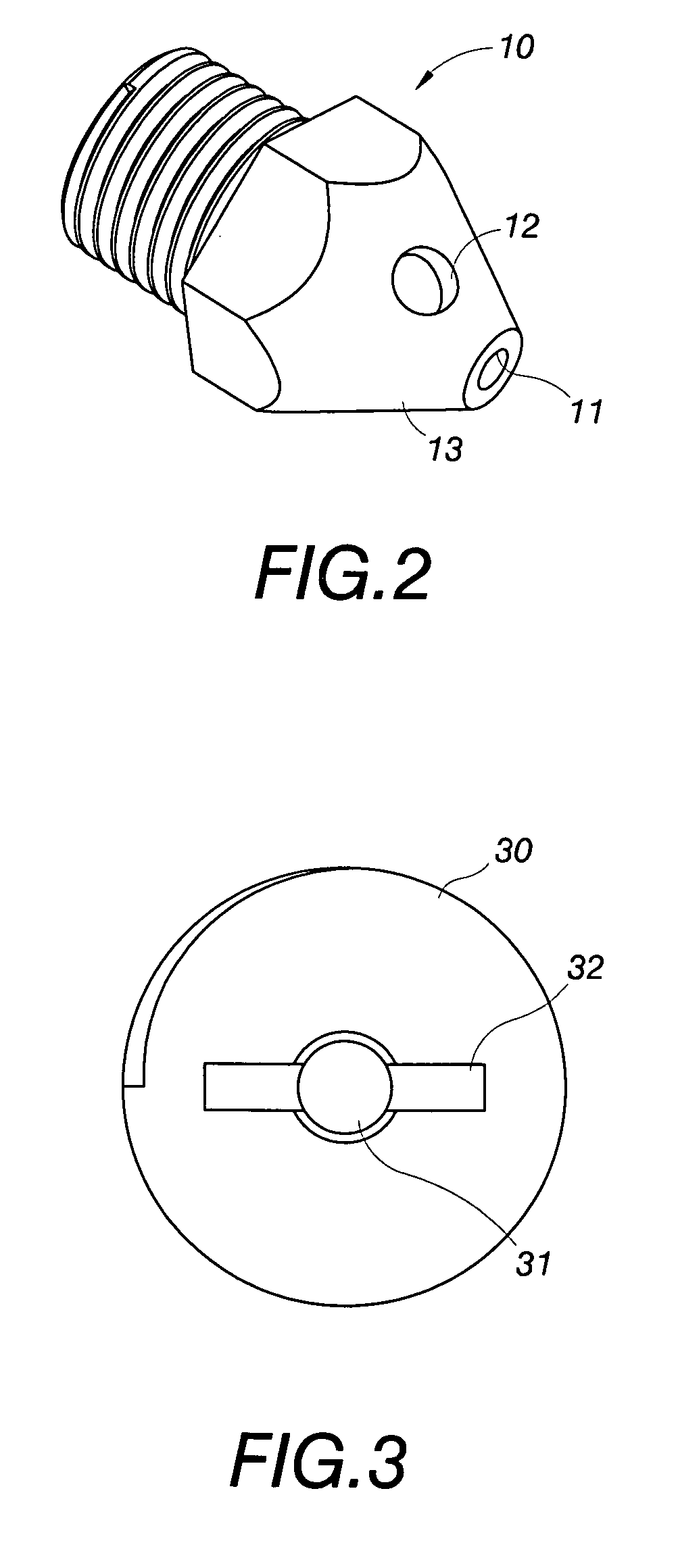

[0037]As illustrated in FIG. 1, a multifunctional fuel gas nozzle according to the present invention comprises a shell 20, a hollow core 10 connected to the fuel gas supply, and a switch strip 30.

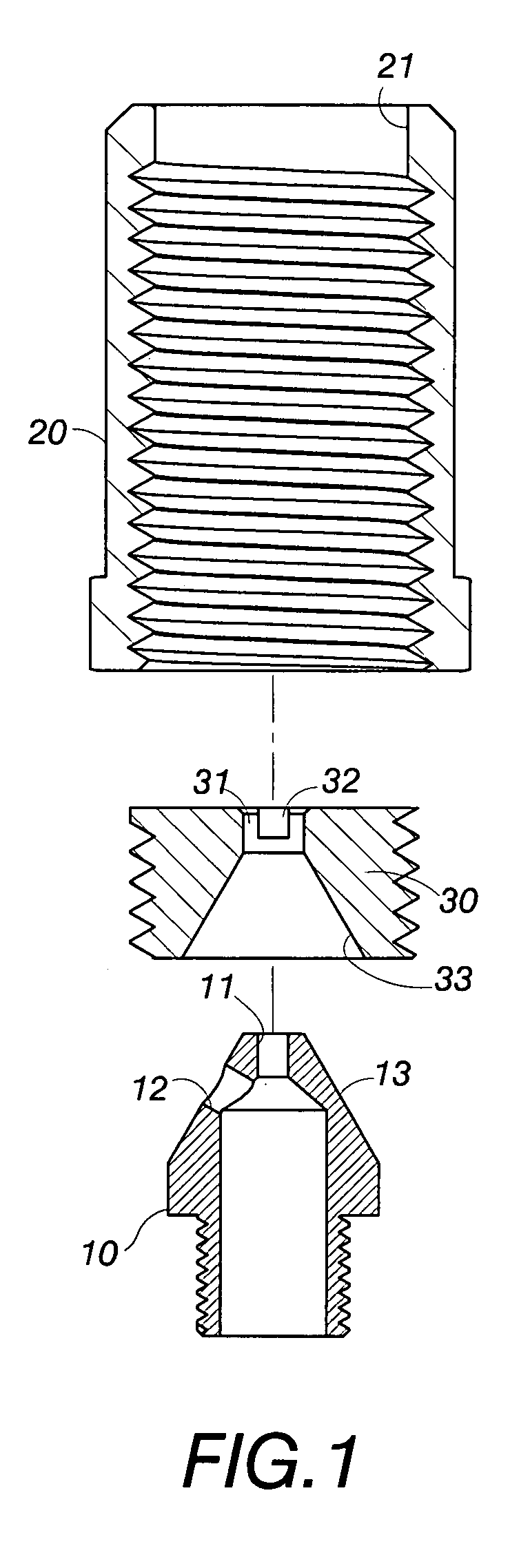

[0038]Wherein, as illustrated in FIGS. 1 to 4, said core 10 is a hollow part, the rear end of which is a cylinder with a turned thread on its surface, and the core is fastened to a valve body 40 via the thread and fastened to the rear end portion of the shell 20 through the thread of the valve body 40. The shape of the front end portion 13 of the core 10 is conical, and a liquefied gas hole is disposed on the top surface of the cone to meet the requirements in use of liquefied gas as a fuel; a lateral aperture 12 is disposed on the conical side surface of the front end portion 13, and the sum of the cross-sectional area of the lateral aperture 12 and that of the liquefied gas hole 11 must satisfy the requirements in use of natural gas as a fuel, that is, the sum of the flow volume through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com