Combined chiller and boiler HVAC system in a single outdoor operating unit

a chiller and boiler technology, applied in the direction of fluid heaters, lighting and heating apparatus, heating types, etc., can solve the problems of noisy forced air systems, inability to deliver simultaneous heating or cooling to selected areas, and total loss of energy required to create warm or cold air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

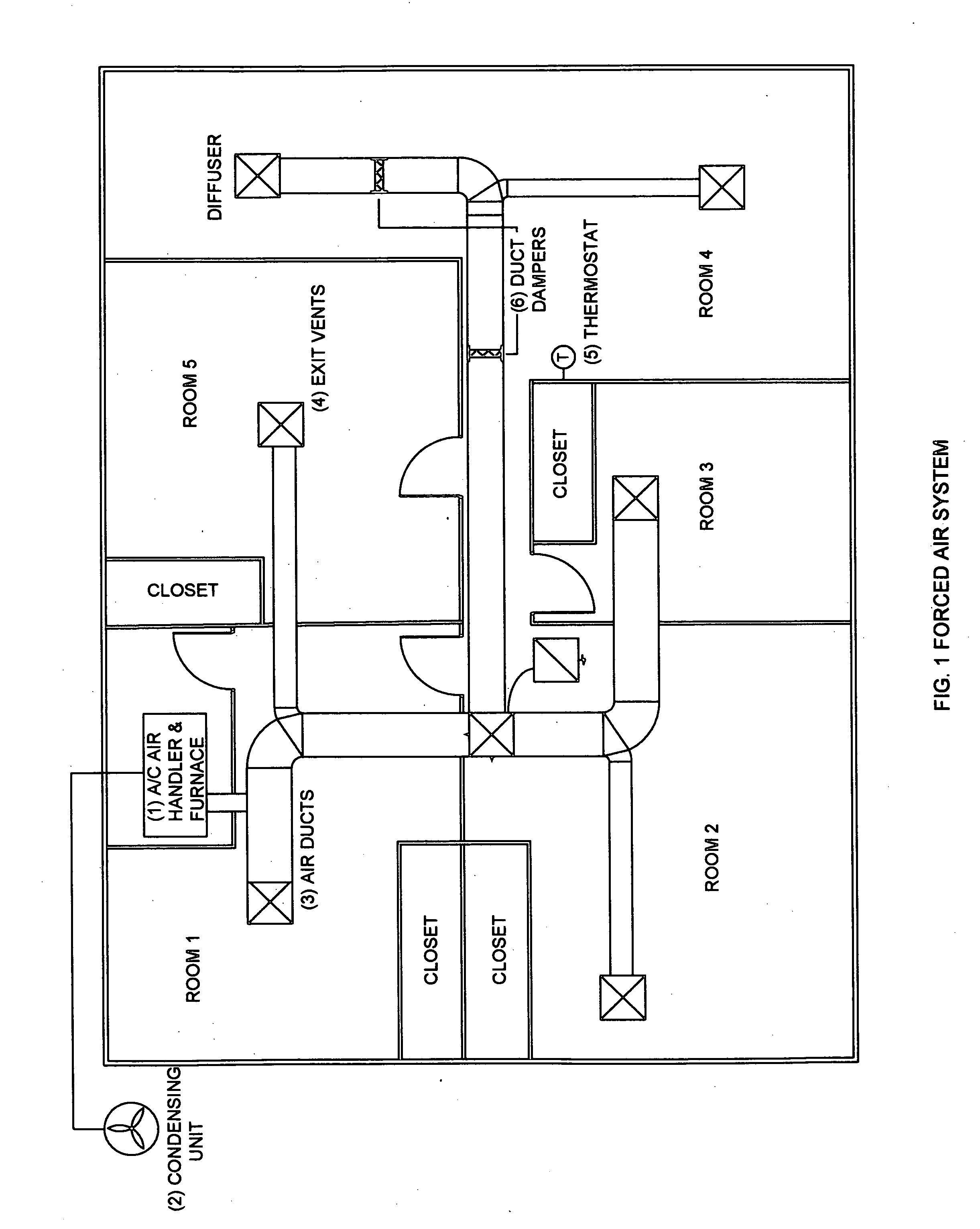

[0034]FIG. 1 shows a typical forced air system employing a heating unit furnace (1) installed in the building and the air conditioning condenser (2) portion of the air conditioning system installed a the exterior of the building. Either heated or cooled air can be selected to be delivered throughout the building via a series of ducts (3) to adjustable exit vents (4) located in the individual rooms in the building. FIG. 1 illustration is a small version of a forced air system however anyone knowledgeable in the state of the art knows that in larger structures there is simply more extensive duct work and larger capacity units. Typically, one thermostat (5) controls the entire system.

[0035]In more complex forced air systems where greater control of temperature gradients is required, the ducting may be further divided into zones which can be manually or electronically adjusted, or programmed to operate automatically, utilizing duct dampers (6) driven by additional thermostats. It must b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com