Turbine Blade With Recessed Tip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074]Subsequent embodiments of the invention are described in more detail. Similar features are in the different drawings marked with the same numbers.

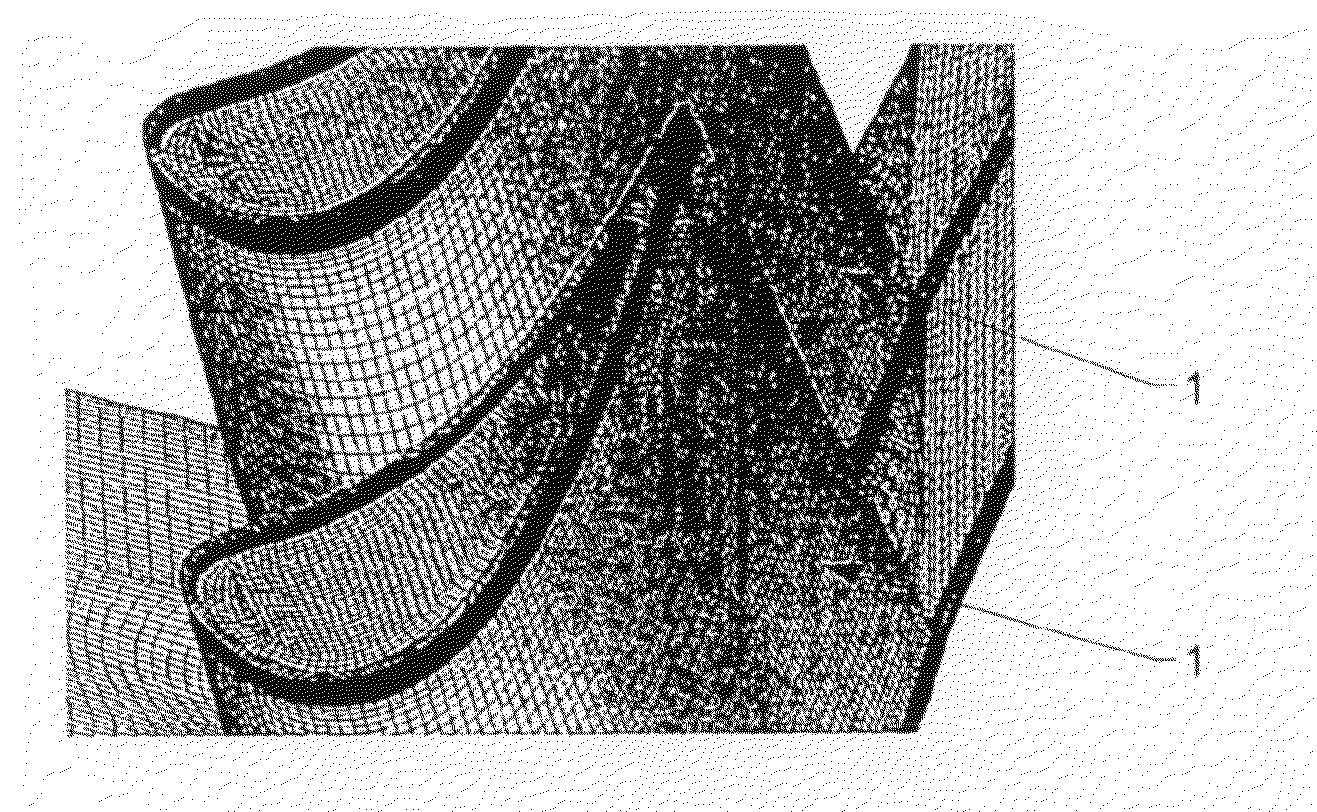

[0075]FIG. 1 shows a computer model of two turbine blades for numerical calculation of the behaviour of a recess arranged at the tip of a turbine blade.

[0076]The analytical models applied are in general based on a numerical grid (mesh) of a turbine blade 1. The numerical grids used were generated with an in-house developed grid generator called MELLIP. A multi block structured grid generator uses a two dimensional NURBS library as input data to mesh the computational domain boundaries. Using a set of geometrical transformations the interior block boundaries are defined according to the intended grid topology. High grid quality, i.e. smooth gridlines, limited aspect ratio, skewness and cell to cell ratios are achieved using both non linear interpolation algorithms with flexible clustering specification and two dimensional Poisson type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com