Acoustically absorbent ceiling tile having barrier facing with diffuse reflectance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

Test Methods

[0048]Basis Weight was measured by the method of ASTM D 3776, modified for specimen size, and reported in units of g / m2.

[0049]Tensile Strength was measured according to ASTM D5035 and reported in units of N / 25.4 cm.

[0050]Gurley Hill Porosity was measured according to TAPPI T460 and reported in seconds.

[0051]Frazier Air Permeability was measured according to ASTM D737-75 in CFM / ft2 at 125 Pa differential pressure.

[0052]Hydrostatic Head was measured according to AATCC TM 127, DIN EN 20811 with a test rate of 60 cm of H2O per minute.

[0053]Parker Surface Smoothness was measured according to TAPPI 555 at a clamping pressure of 1.0 MPa and is reported in micrometers.

[0054]Specific Airflow Resistance is equivalent to the air pressure difference across a sample divided by the linear velocity of airflow measured outside the sample and is reported in Ns / m3. The values reported herein were determined as follows. The volumetric air flow Q was calculated by dividing the air permeabil...

examples 1-2

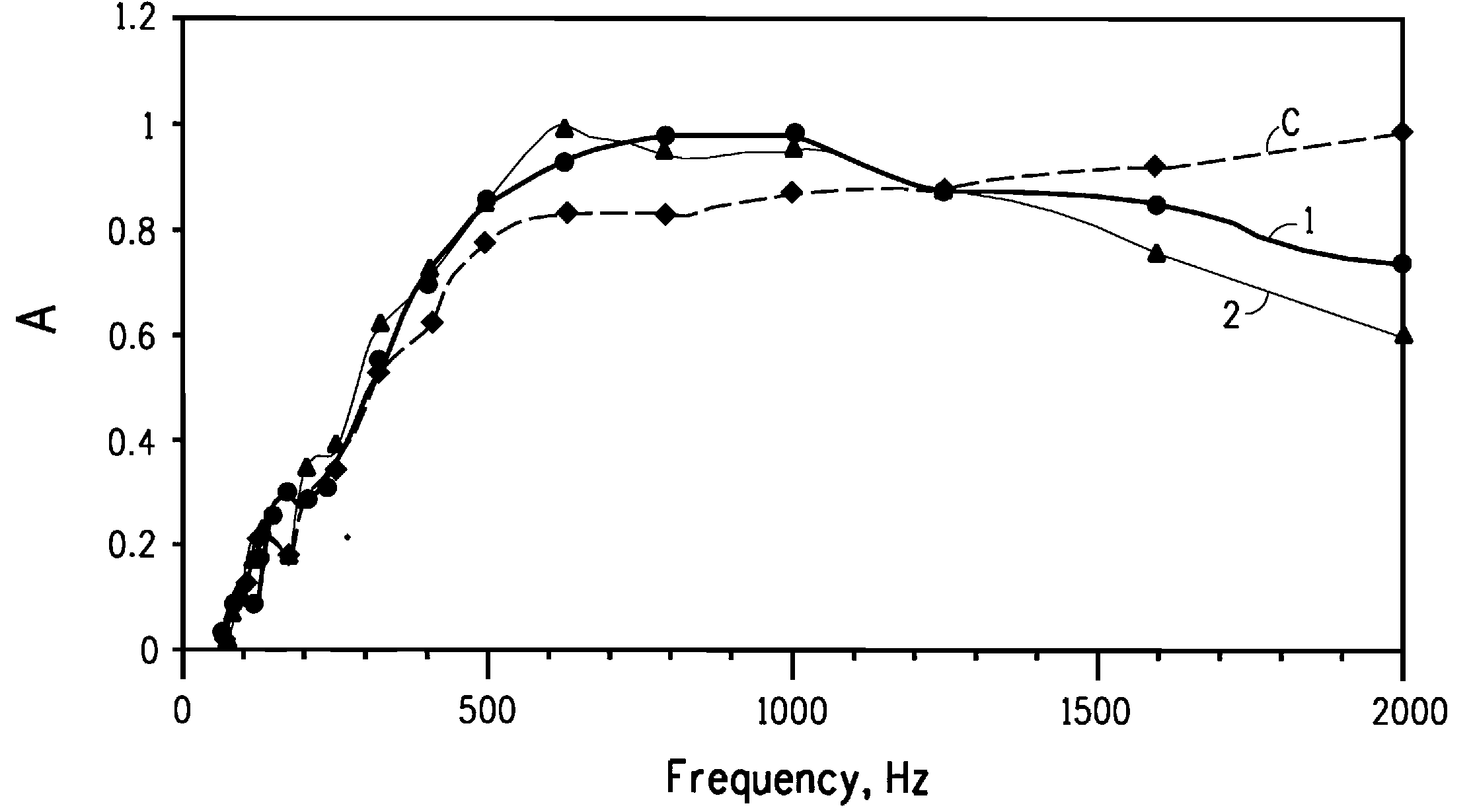

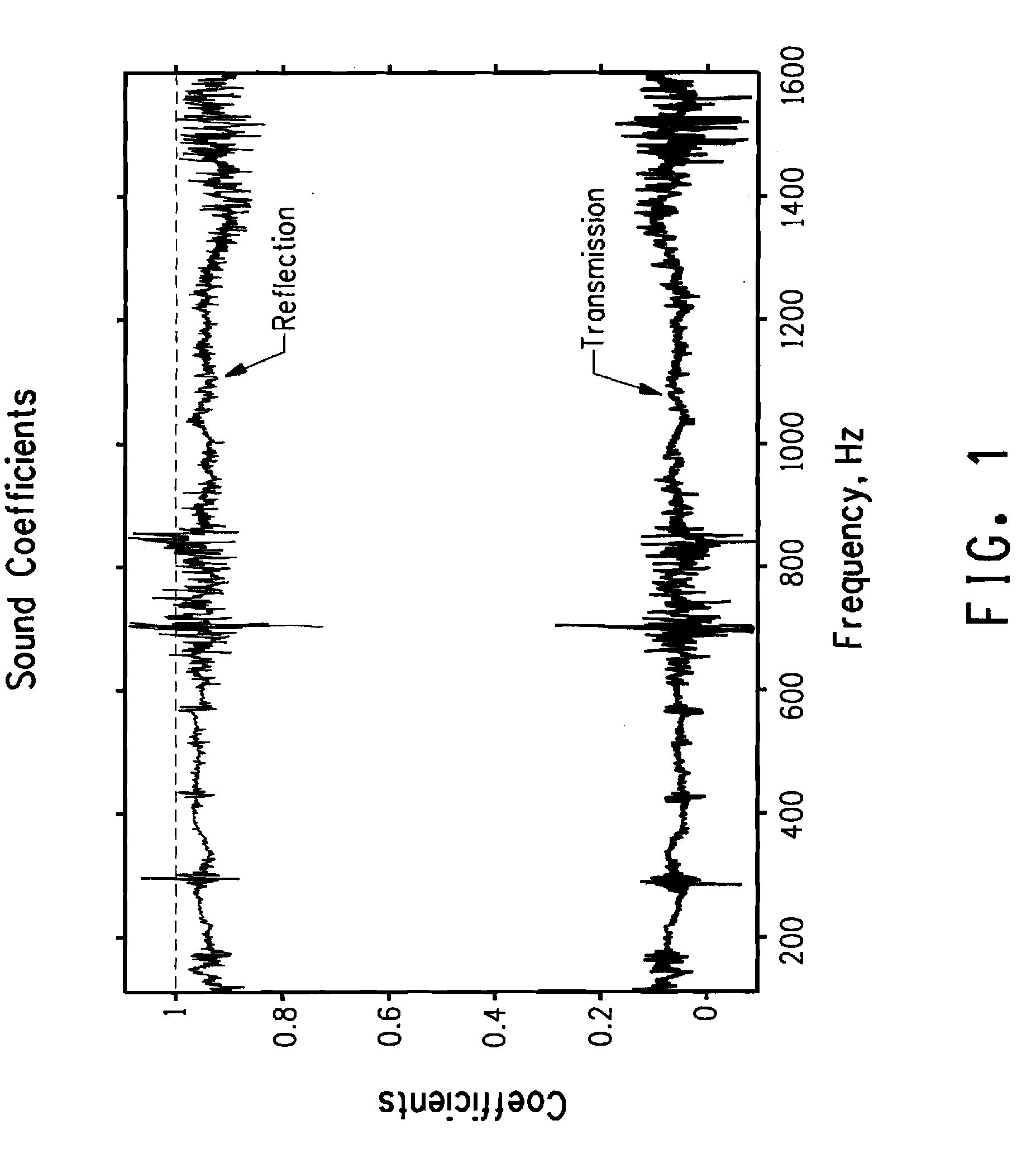

[0063]Samples of acoustically absorbing material according to the invention were formed using a layer of open cell melamine foam (from Illbruck Acoustic Inc., Minneapolis, Minn.) having a thickness of 13 mm, a basis weight of 9.4 kg m3 and a specific airflow resistance of 120 rayls. A 0.1 mm thick, 17 g / m2 basis weight nylon 6, 6 spunbond scrim was laid on both sides of the foam and the scrims and foam were quilted together using a pattern of approximately 11 cm×11 cm diamonds. The acoustically absorbing samples were made by the lamination process described below. A vinyl acetate water based glue (WA 2173 available from efi Polymers, Denver, Colo.) was applied by a roller onto one surface of the quilted foam layer at a rate of approximately 0.3 kg / m2. A melt blown polyester nonwoven layer having a thickness of 20 mm, a basis weight of 0.33 kg / m2, and a specific airflow resistance of 130 rayls was laminated to the quilted foam layer to form the absorber core. A flash spun nonwoven fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com