Simultaneous metal, sulfur and nitrogen removal using supercritical water

a technology of supercritical water and metals, applied in the direction of hydrocarbon oil treatment, liquid carbonaceous fuels, fuels, etc., can solve the problems of high operating cost of hydrogen-addition process, and negative effect of contaminants on catalysts and equipment used in many processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Experimental Process Description

[0047]A bomb reactor was loaded with a water and a heavy oil feed with API=12.8, which was a heavy crude oil which was diluted with a diluent hydrocarbon at a ratio of 5:1 (20 vol % of diluent). The reactor was immersed in a sand bath at reaction temperature so the temperature inside the reactor was quickly raised to ˜400° C., typically in 3 to 5 minutes. The reaction time was 30 minutes, and after reaction the reactor was quickly cooled down. The upgraded oil product and water were then recovered from the bomb reactor.

[0048]The properties of the heavy crude feed were as follows: 12.8 API gravity at 60 / 60; 1329 CST viscosity @40° C.; 13.04 wt % MCRT; 3.54 wt % sulfur; 0.56 wt % nitrogen; 3.05 mg KOH / gm acid number; 1.41 wt % water; 371 ppm Vanadium; and 86 ppm Nickel.

[0049]After the super critical water treatment upgraded product (syncrude) had the following properties: 19.2 API gravity at 60 / 60; 3.15 wt % MCRT; 0.54 wt % sulfur; 0.21 wt % nitrogen; 5...

example 2

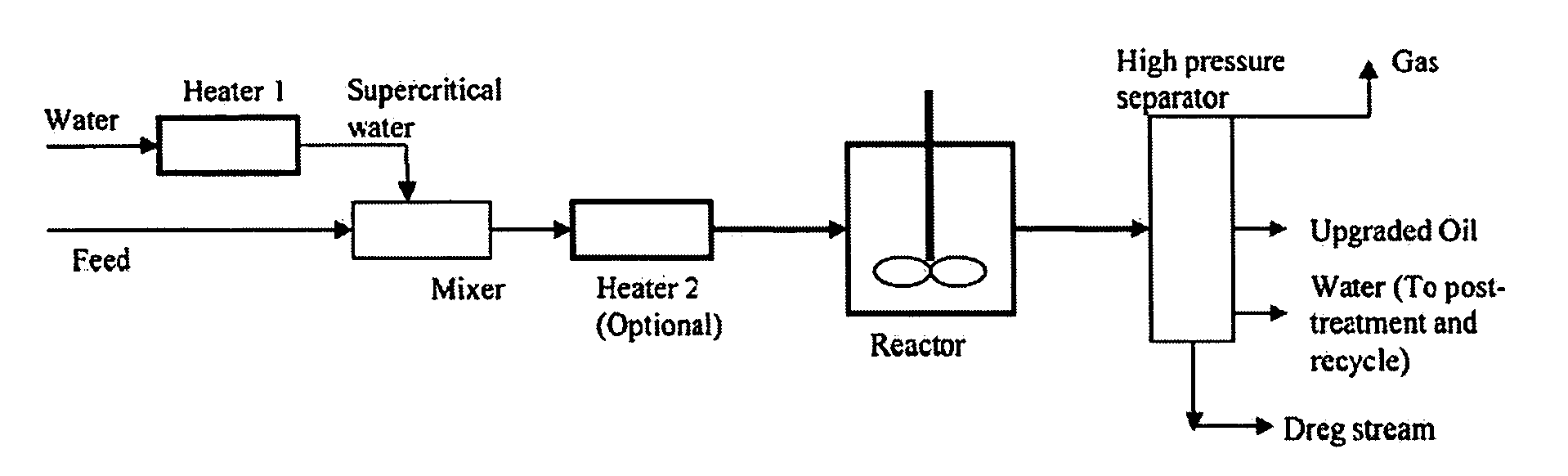

[0050]The following procedure was performed using a continuous system. The feed oil was heated to 130° C. before entering a mixer. The heated crude was injected into a stream of supercritical water at temperature of 400° C. The water to oil ratio (volume at room temperature) was 3:1. The oil-supercritical water mixture was then injected into a reactor at temperature of 400° C. and pressure of 3400 psig. The upgraded product, which formed a homogeneous phase with supercritical water, was withdrawn from the top of the reactor and send to high pressure separator which was operated at the same pressure but lower temperature to achieve oil-water separation. The dreg stream was removed from reactor bottom.

[0051]The properties of the feed crude in Example 2 were as follows: 8 API gravity at 60 / 60; 65689 CST viscosity @40° C.;. 15.7 wt % MCRT; 4.17 wt % sulfur; 0.68 wt % nitrogen; 5.8 mg KOH / gm acid number; 435 ppm Vanadium; and 104 ppm Nickel.

[0052]After the super critical water treatment ...

example 3

[0053]The procedure of Example 2 was repeated except that the properties of the feed crude were as follows: 8 API gravity at 60 / 60; 20,400 CST viscosity @40° C.; 13 wt % MCRT; 5 wt % sulfur; 0.48 wt % nitrogen; 3.8 mg KOH / gm acid number; 215 ppm Vanadium; and 80 ppm Nickel.

[0054]After the super critical water treatment upgraded product (syncrude) had the following properties: 18 API gravity at 60 / 60; 21 CST viscosity @40° C. 3 wt % MCRT; 4 wt % sulfur; 0.27 wt % nitrogen; 41 ppm Vanadium; and 8 ppm Nickel.

[0055]For Examples 2 and 3, substantial reductions in metals, nitrogen and sulfur were observed, with simultaneous increase in the API gravity and a significant decrease in the viscosity of the original crude oil feedstock.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com