Process for assembling substrates with low-temperature heat treatments

a heat treatment and substrate technology, applied in the direction of lamination, decorative surface effects, decorative arts, etc., can solve the problems of formation of bonding defects, inability to use solutions, appearance of defects at the bonding interfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

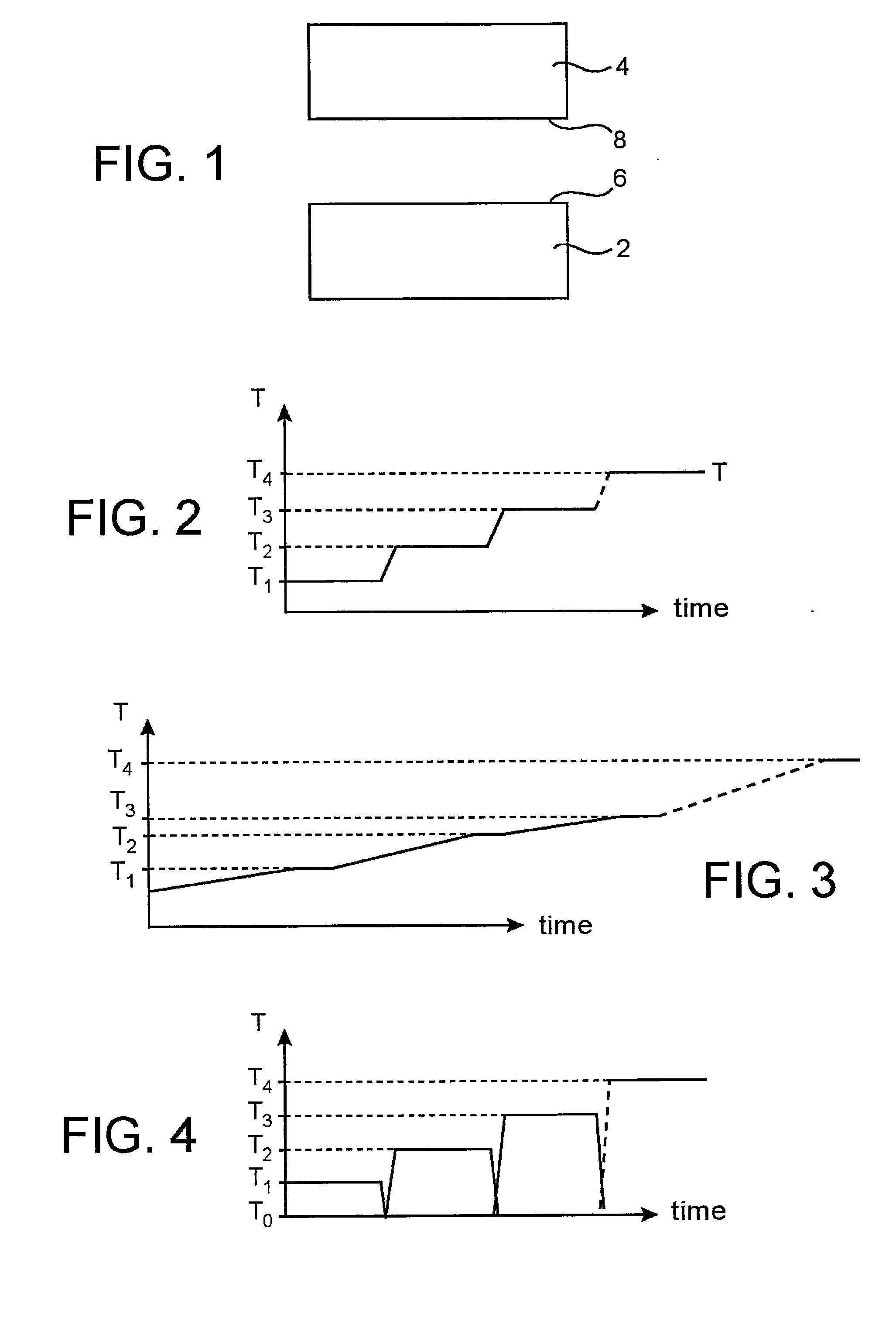

example 1

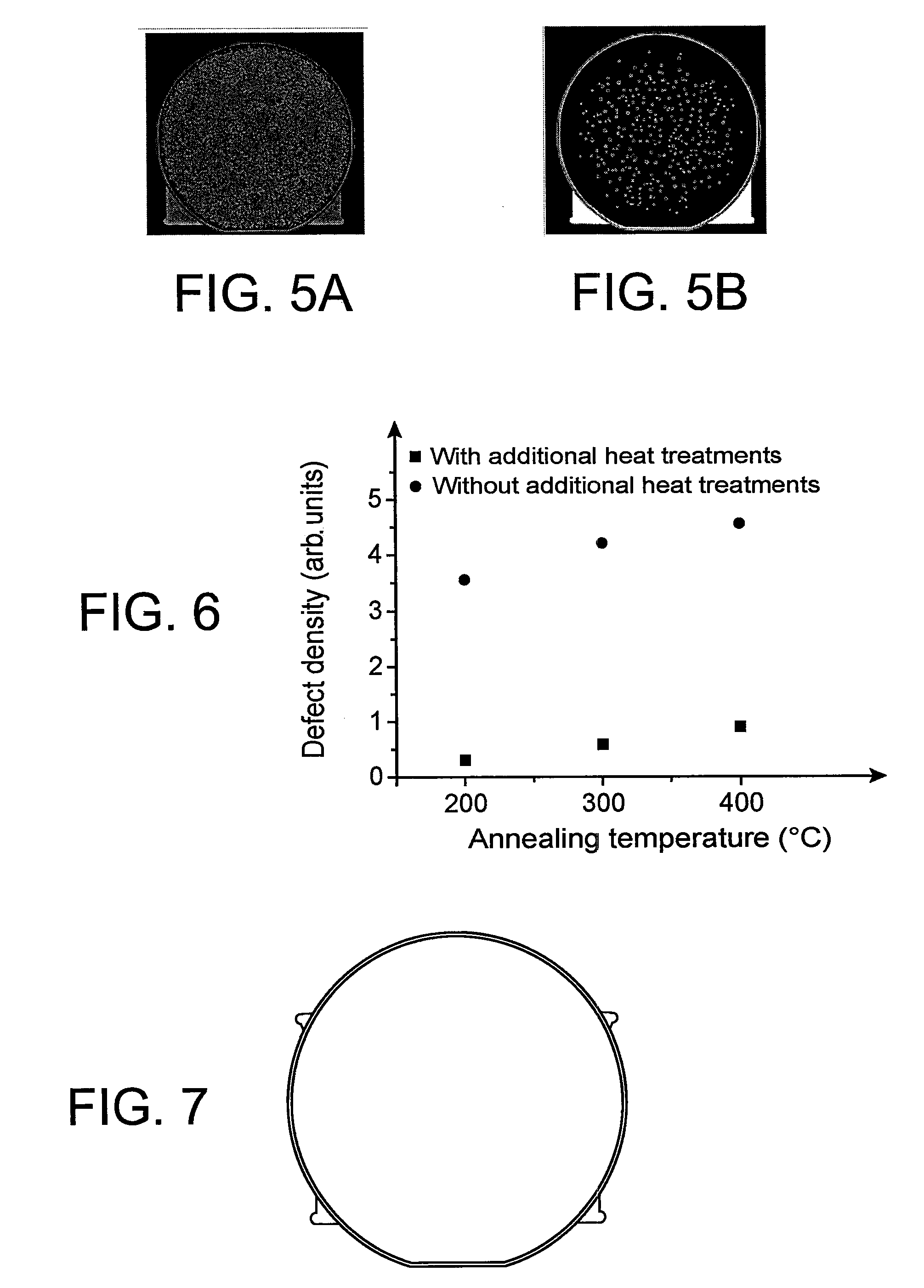

[0137]By optimising the preliminary surface preparations, for example by preparing surfaces 6 and 8 by microwave plasma in an oxygen atmosphere and producing a bond between the two surfaces under vacuum with heating to 300° C. during the bonding, it was possible to obtain an Si—Si bond, without defects at the bonding interface (as shown in FIG. 7) under the following conditions:[0138]a heat treatment according to the invention is first performed, which treatment comprises a slow ramp of 1° C. / min, starting at room temperature, then having levels of a duration of 10 hours each at 100° C., then at 200° C., then at 300° C., and so on by levels of 100° C. until reaching the final temperature of 700° C.,[0139]a “standard” bonding reinforcement heat treatment, in the range of 600 to 700° C.

[0140]FIG. 7 shows an acoustic microscopy image of this Si—Si bonding interface, after heat treatment by levels according to the invention, followed by a consolidation treatment at 700° C. for 2 hours. ...

example 2

[0141]By chemically preparing the surfaces, for example with an attack by HF in solution, so that they become hydrophobic, it was possible, with a heat treatment according to the invention, to obtain defect-free bonding interfaces at up to 500° C. and more. The heat treatment according to the invention is a slow ramp, of 0.15° C. / min, starting at room temperature, combined with levels, each lasting 10 hours, at 100° C., then at 200° C., then at 300° C., and so on by levels of 100° C. until reaching the final temperature of 500° C.

[0142]Various other applications of a process according to the invention can be mentioned.

[0143]The use of additional heat treatments according to the invention makes it possible to produce stacked structures by molecular bonding with minimal or even no bonding defects. Among the various applications, it is then possible to produce thin films (for example below 100 μm or 1 μm or 0.1 μm) is possible.

[0144]For example, the initial structure is obtained by bon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com