Modular building system and methods thereof

a modular building system and building technology, applied in the field of modular building systems, can solve the problems of large variability in the quality of wood boards, high cost of wood, and inability to meet the needs of construction, and achieve the effects of lateral stability, increased strength, and resistance to axial loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]As required, detailed embodiments of the present invention are disclosed herein; however, it is to be understood that the disclosed embodiments are merely exemplary of the invention, which may be embodied in various forms. Figures are not necessarily to scale, and some features may be exaggerated to show details of particular components or steps.

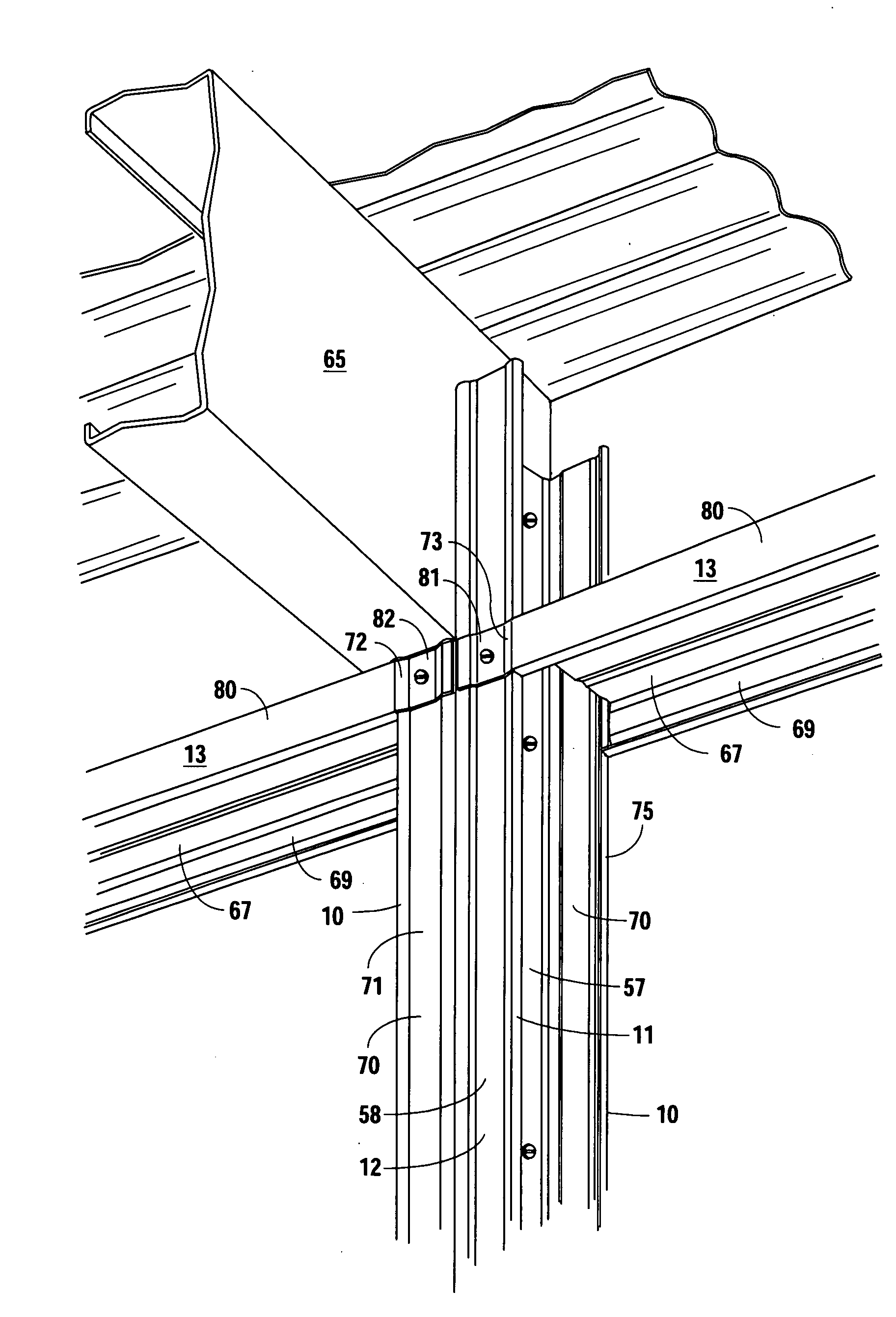

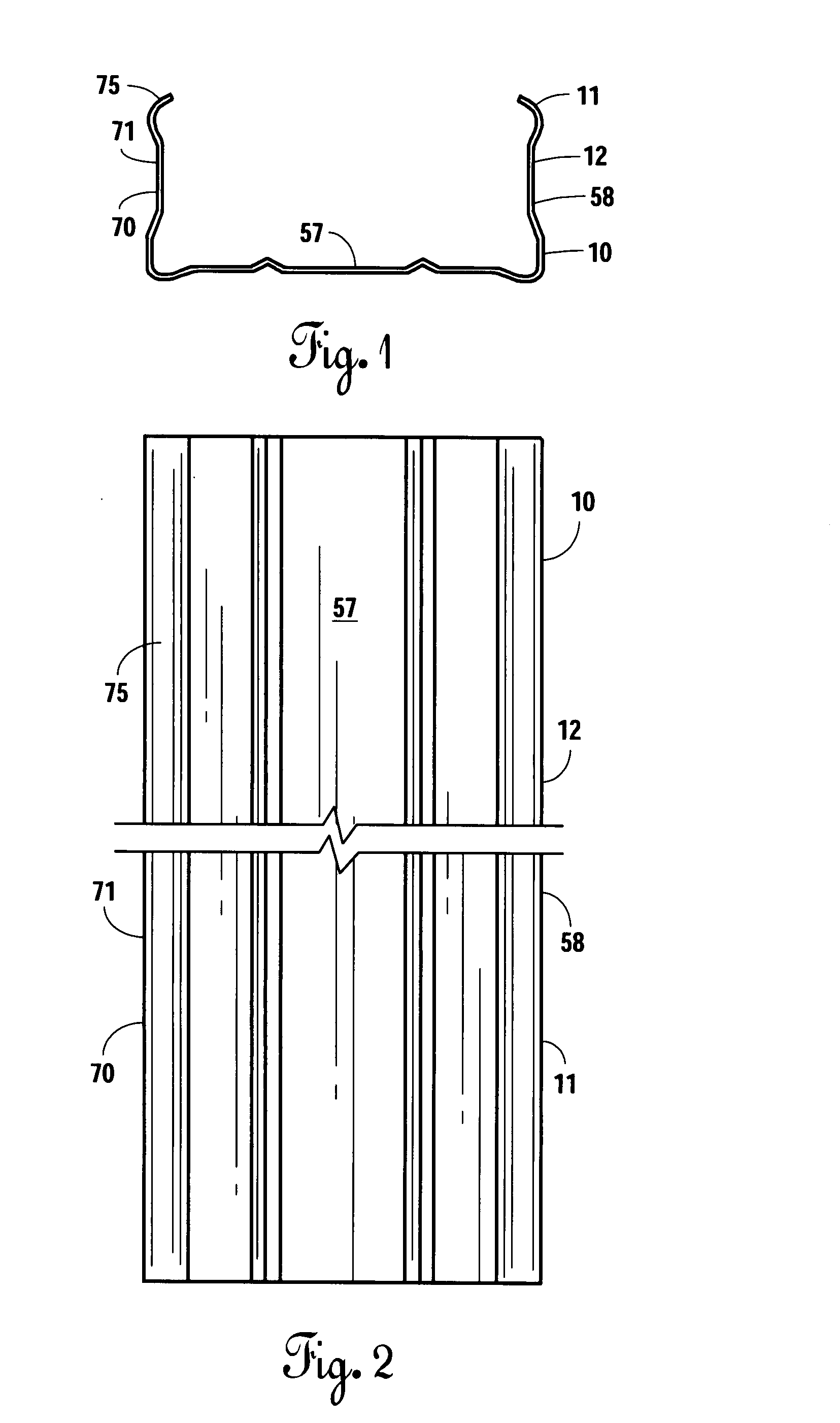

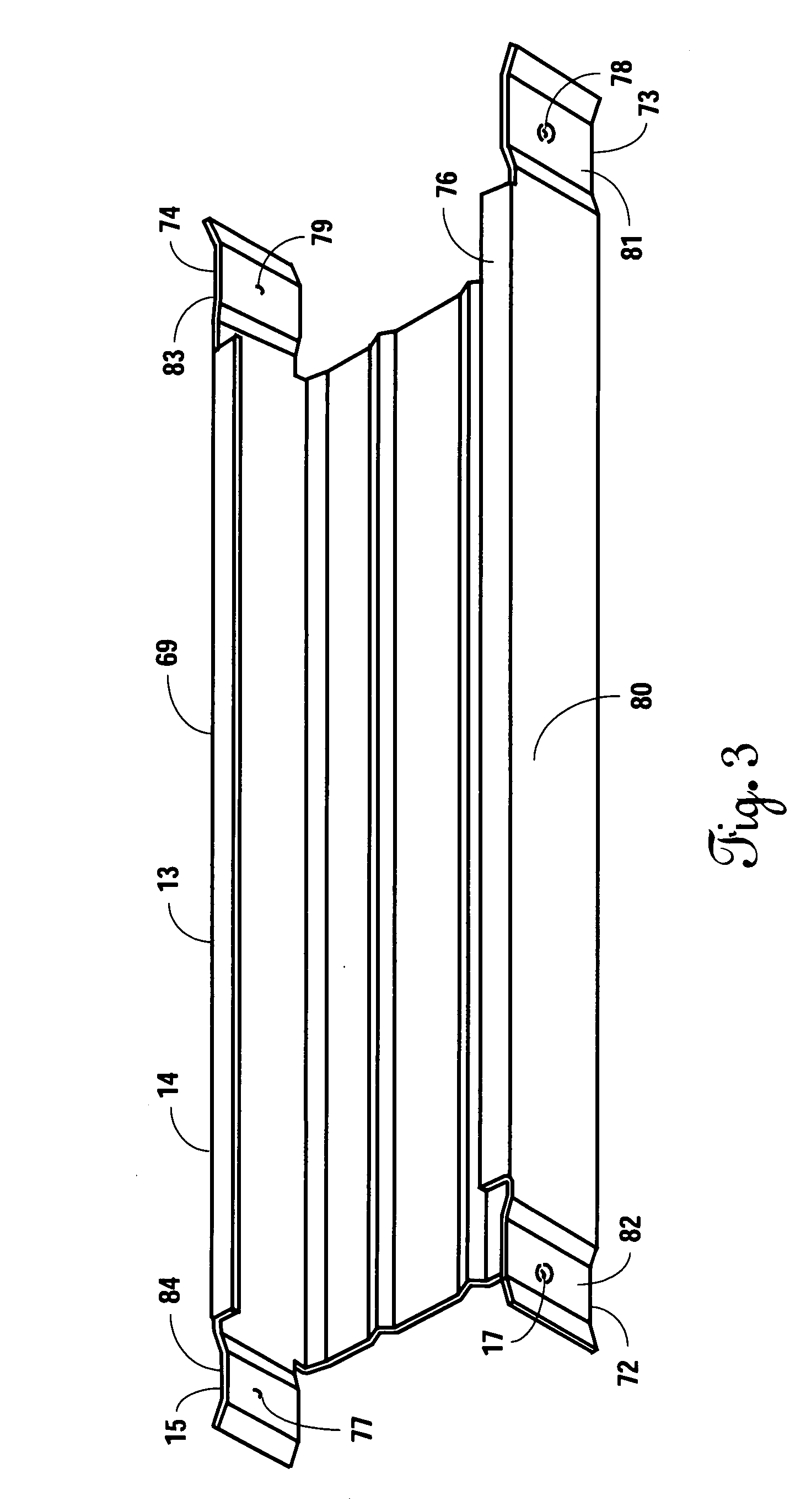

[0031]FIG. 4 illustrates the components comprising the steel space-frame construction system 5 of the present invention. The components include a stud 10, a block 13 a channel 16, and under certain circumstances a top cap 17. The components are configurable into a space-frame 50, which, in turn, includes at least one channel 16, at least two studs 10, and at least one block 13, and under certain circumstances at least one top cap 17 or a second block 13. While a space-frame 50 may include the minimum components recited, a typical space-frame 50 as illustrated in FIG. 9 will include multiple components and will form a structure or a por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com