System and method for power production using a hybrid helical detonation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

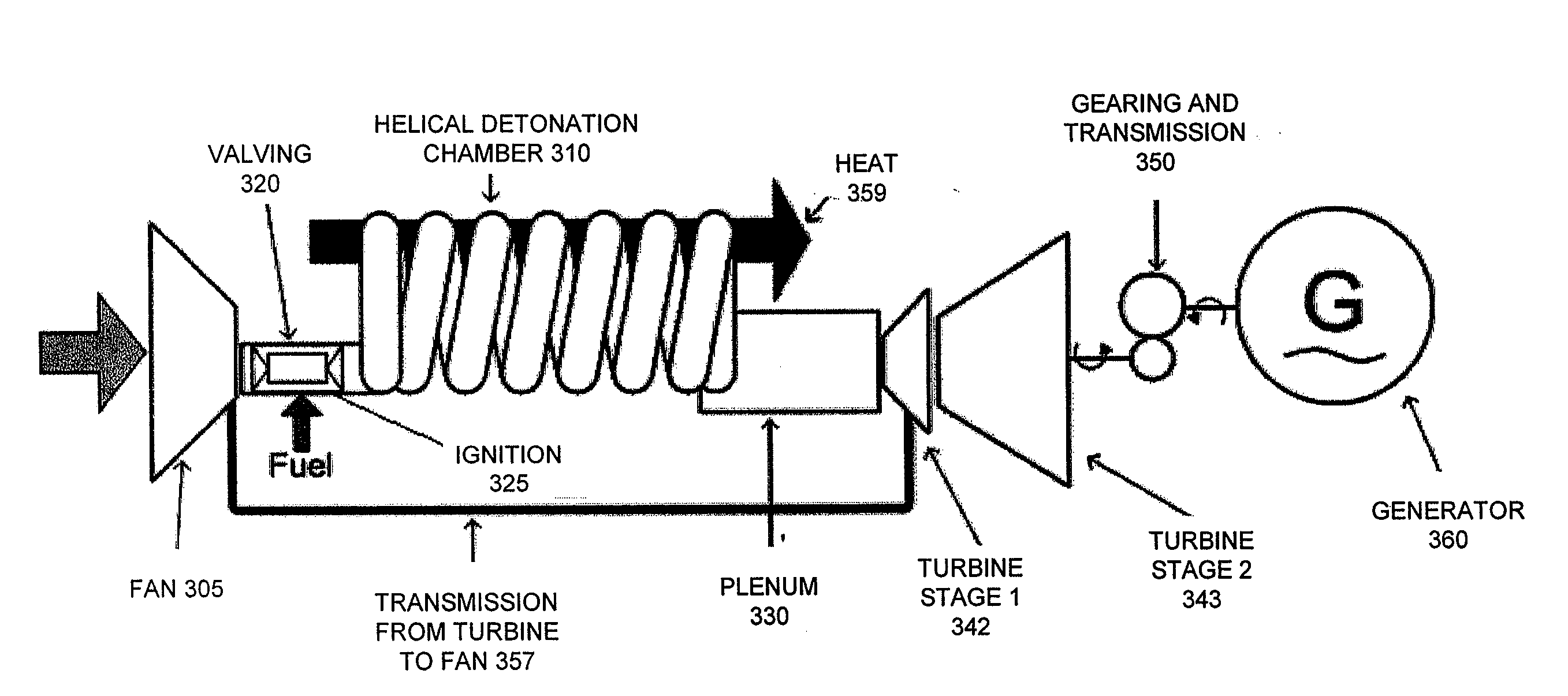

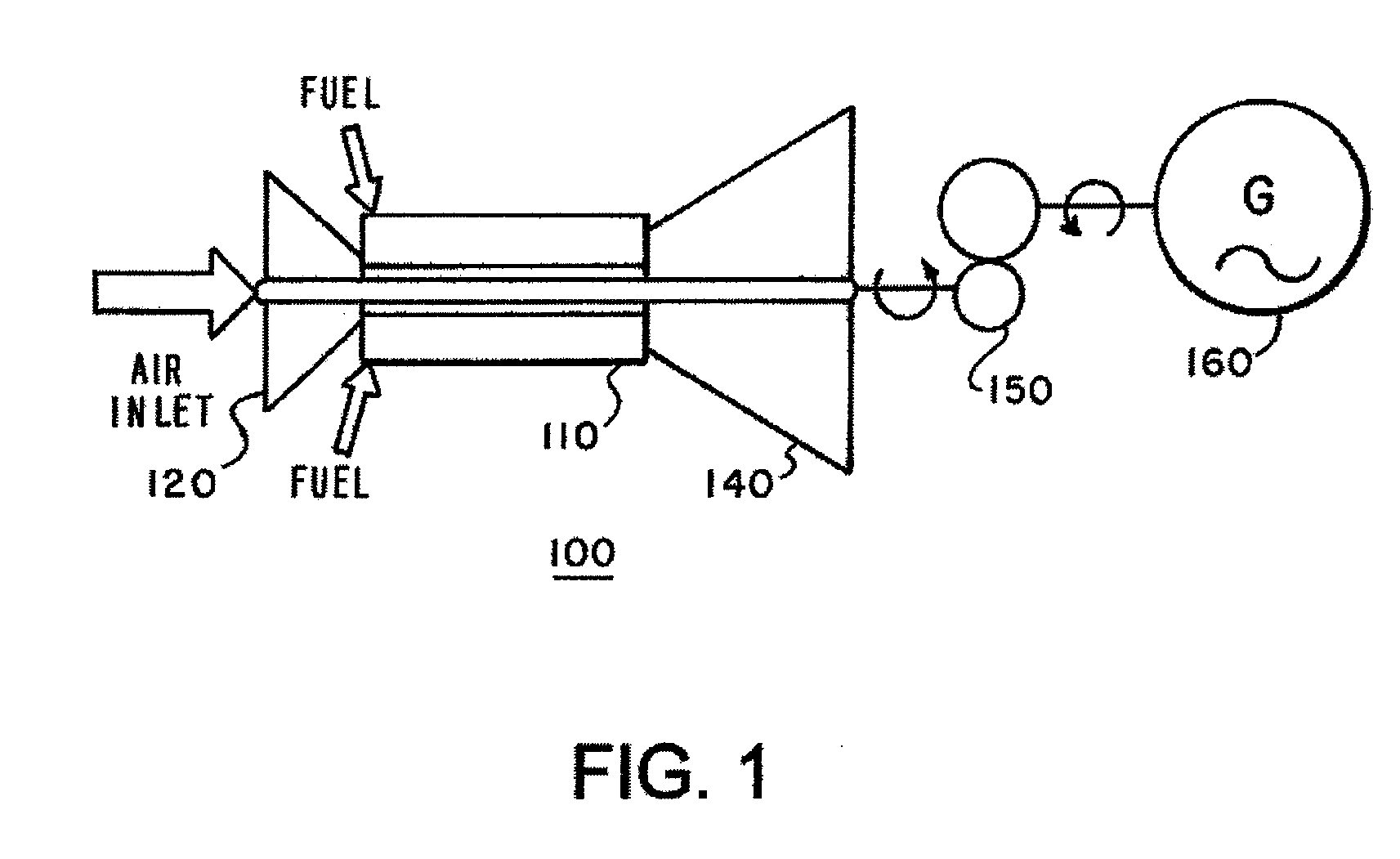

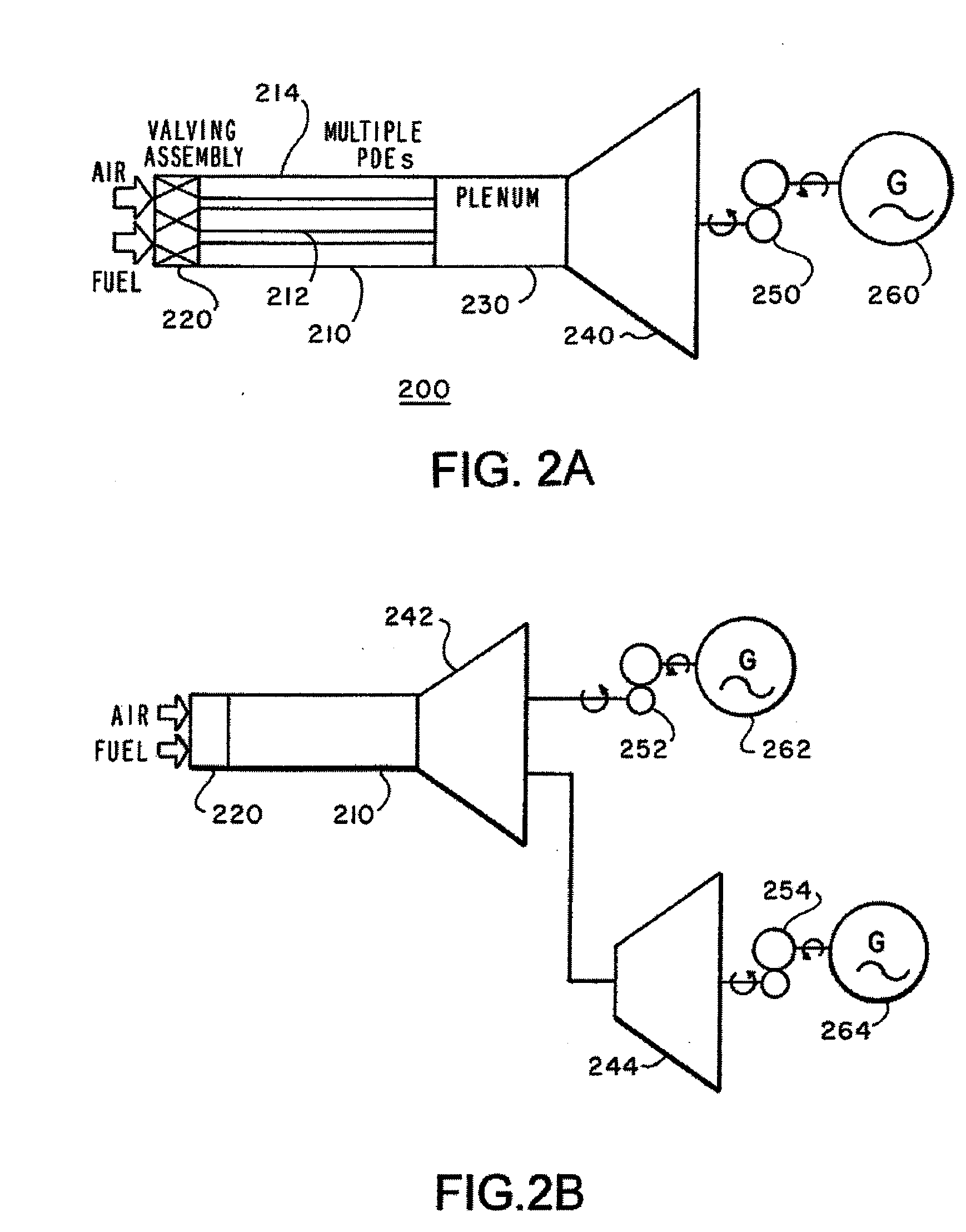

[0025]The invention, as defined by the claims, may be better understood by reference to the following detailed description. The description is meant to be read with reference to the Figures contained herein. This detailed description relates to examples of the claimed subject matter for illustrative purposes, and is in no way meant to limit the scope of the invention. Element numerals are consistent, where possible, across Figures. The specific aspects and embodiments discussed herein are merely illustrative of ways to make and use the invention, and do not limit the scope of the invention.

[0026]A pulsed detonation engine (PDE) in its simplest form essentially consists of a constant area tubular combustion (detonation) chamber with inlet valves to control the flow of fluid into the detonation chamber. The PDE cycle has four states. In the filling stage, the fuel and air inlet valves are opened to allow a fuel and air mixture to fill the tube. This is followed by the initiation and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com