Two-stage compression rotary compressor

a rotary compressor and compression technology, applied in the direction of positive displacement liquid engine, lighting and heating apparatus, liquid fuel engine, etc., can solve the problems of significant pressure loss and efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]Exemplary embodiments of a two-stage compression rotary compressor according to the present invention are described below with reference to the accompanying drawing. Although the invention has been described with respect to a specific embodiment for a complete and clear disclosure, the appended claims are not to be thus limited but are to be construed as embodying all modifications and alternative constructions that may occur to one skilled in the art which fairly fall within the basic teaching herein set forth. The constituent elements in the embodiment described can be easily envisioned by those skilled in the art or can be virtually the same as described here.

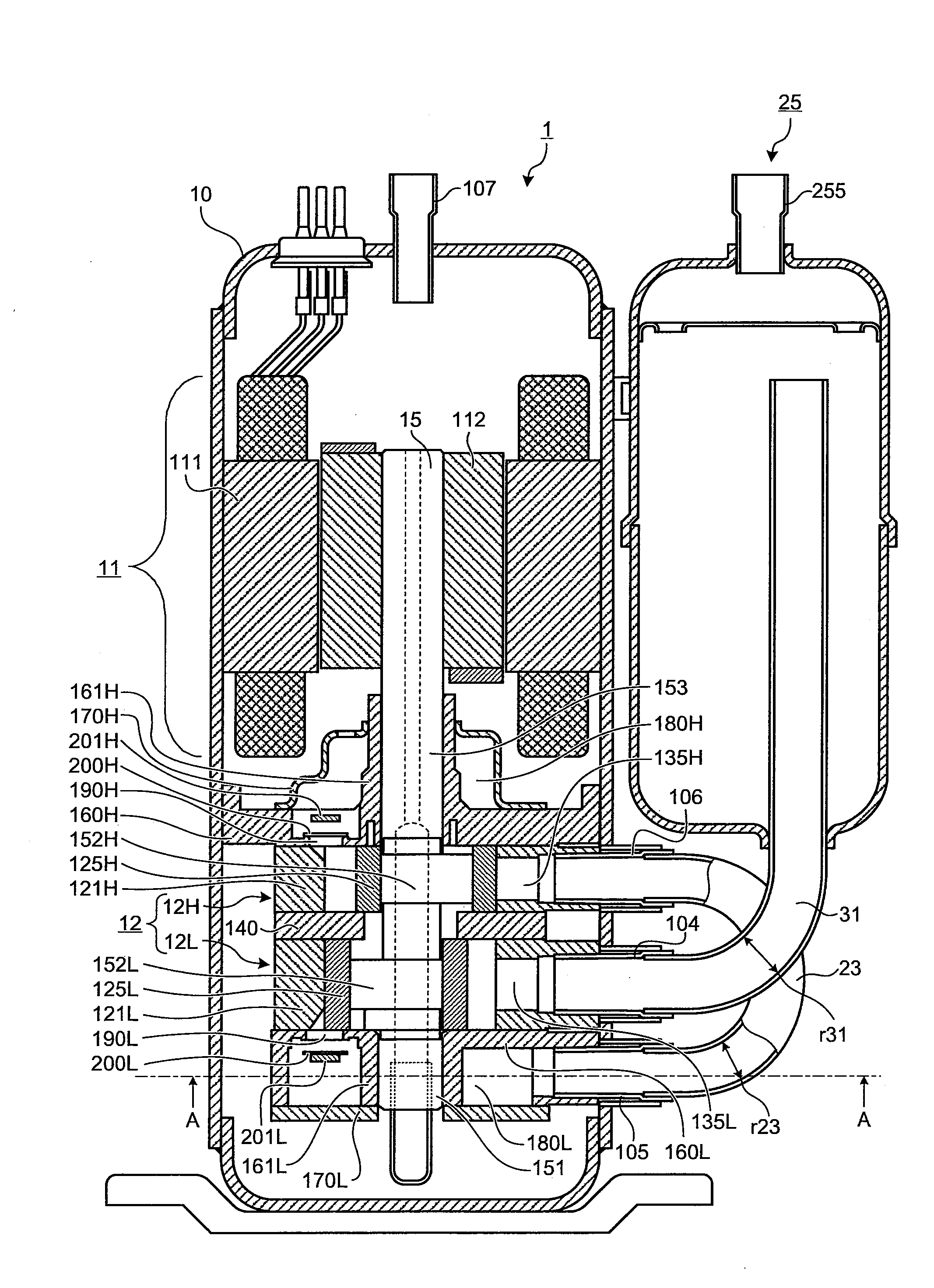

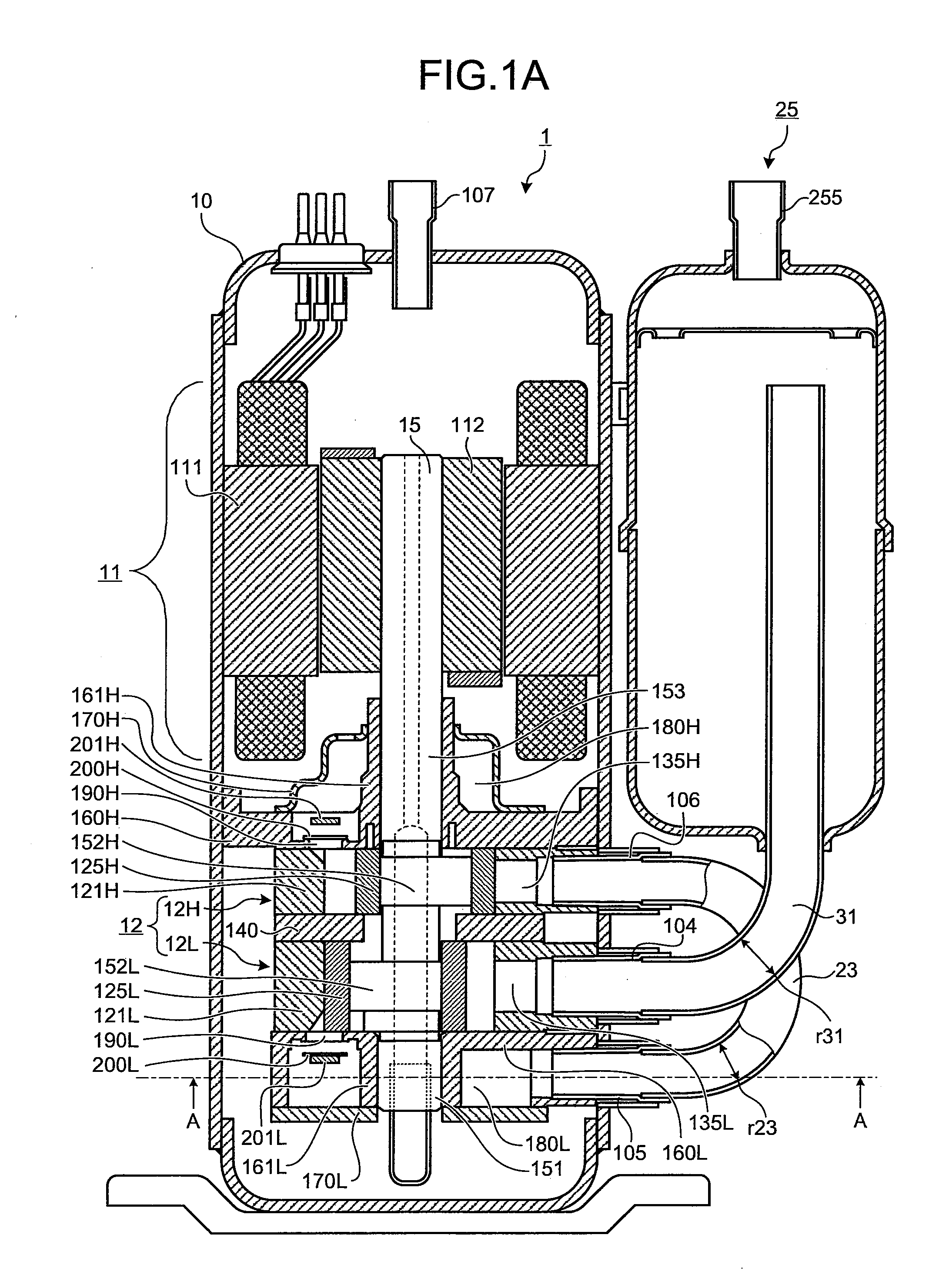

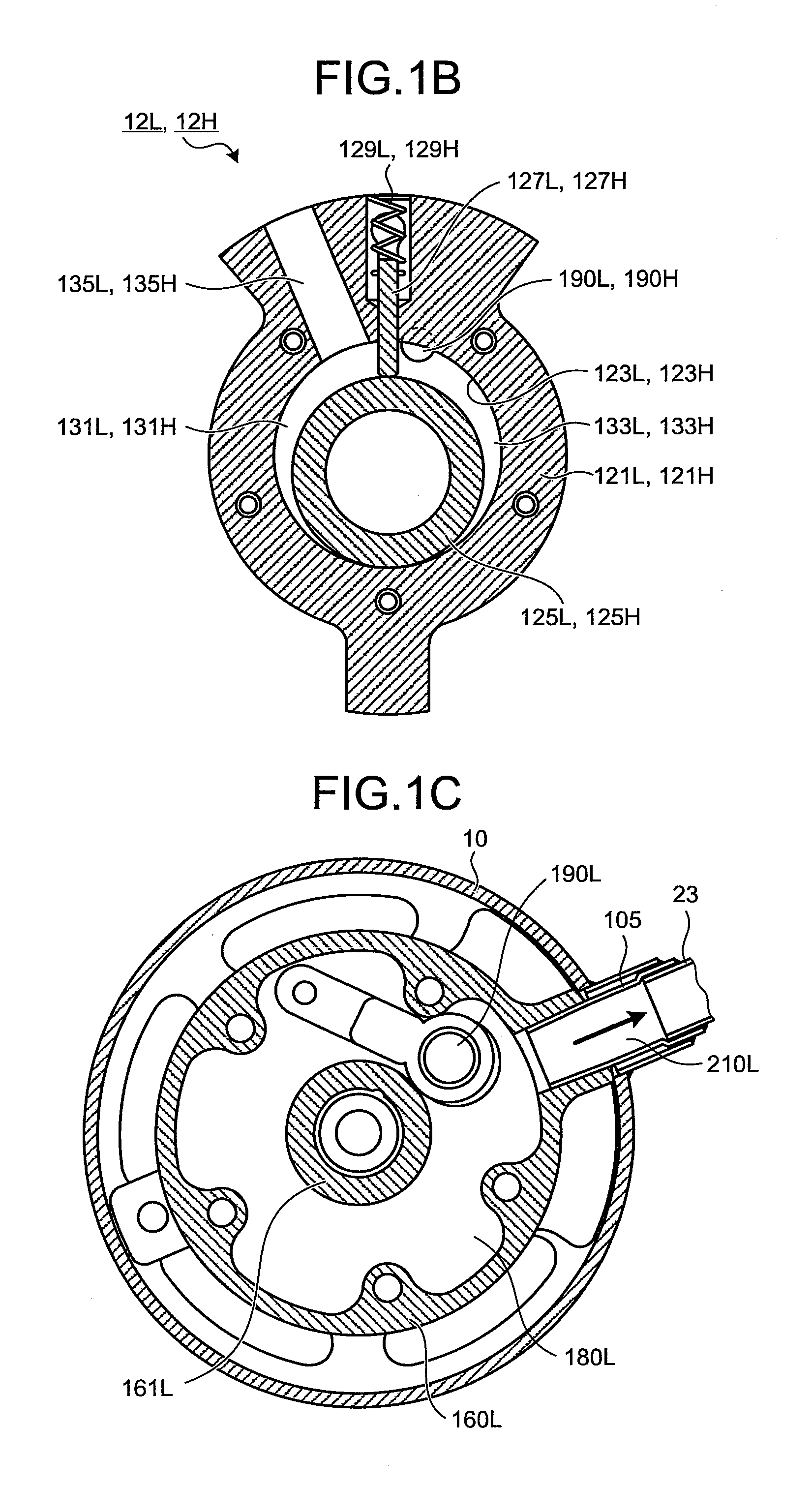

[0022]FIG. 1A is a cross-sectional view of a two-stage compression rotary compressor 1 according to a first embodiment of the present invention. The two-stage compression rotary compressor 1 includes a cylindrical sealed housing 10 disposed vertically with a compressing section 12 and a motor 11 that drives the compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com