Optical semiconductor device and manufacturing method therefor

a technology of optical semiconductor and manufacturing method, which is applied in the direction of semiconductor/solid-state device manufacturing, semiconductor/semiconductor devices, electrical apparatus, etc., can solve the problems of increasing the density of threading dislocation of nitride semiconductor thin films, and achieve the effect of reducing threading dislocation and improving the maximum power of ultraviolet leds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

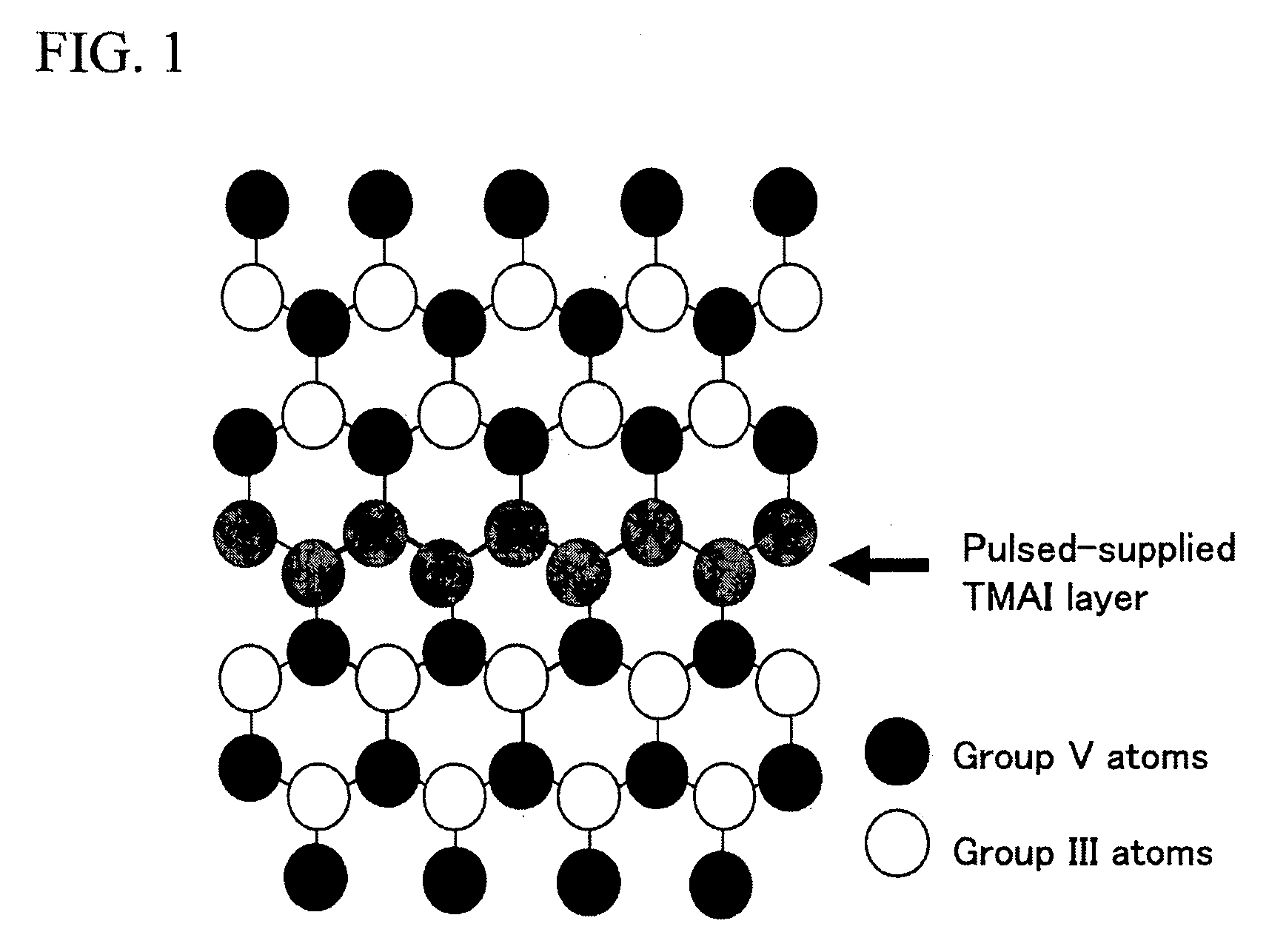

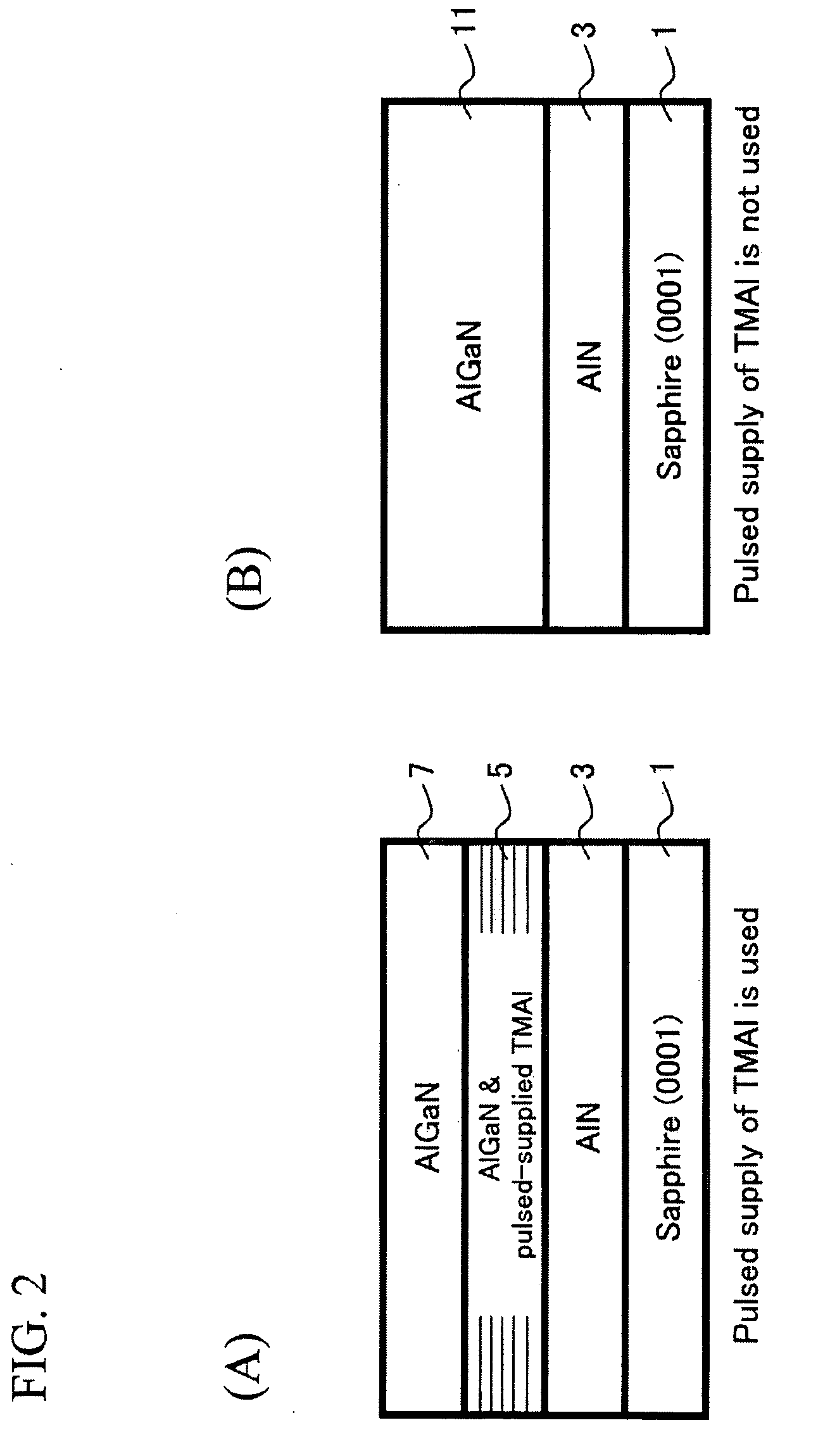

[0033]Prior to description of an embodiment of the present invention, there will be described considerations of the deep ultraviolet light emitting device by the inventor. The inventor has come to realize that controlling the polarity of group III compounds, such as AlGaN-based compounds, is very important. For example, when AlN is to be grown on a sapphire substrate, the polarity of AlN is unstable, and it is important to control the polarity of AlN to be the stable group III polarity. The inventor has found that the stable group III polarity can be achieved by pulsed supply of TMAl.

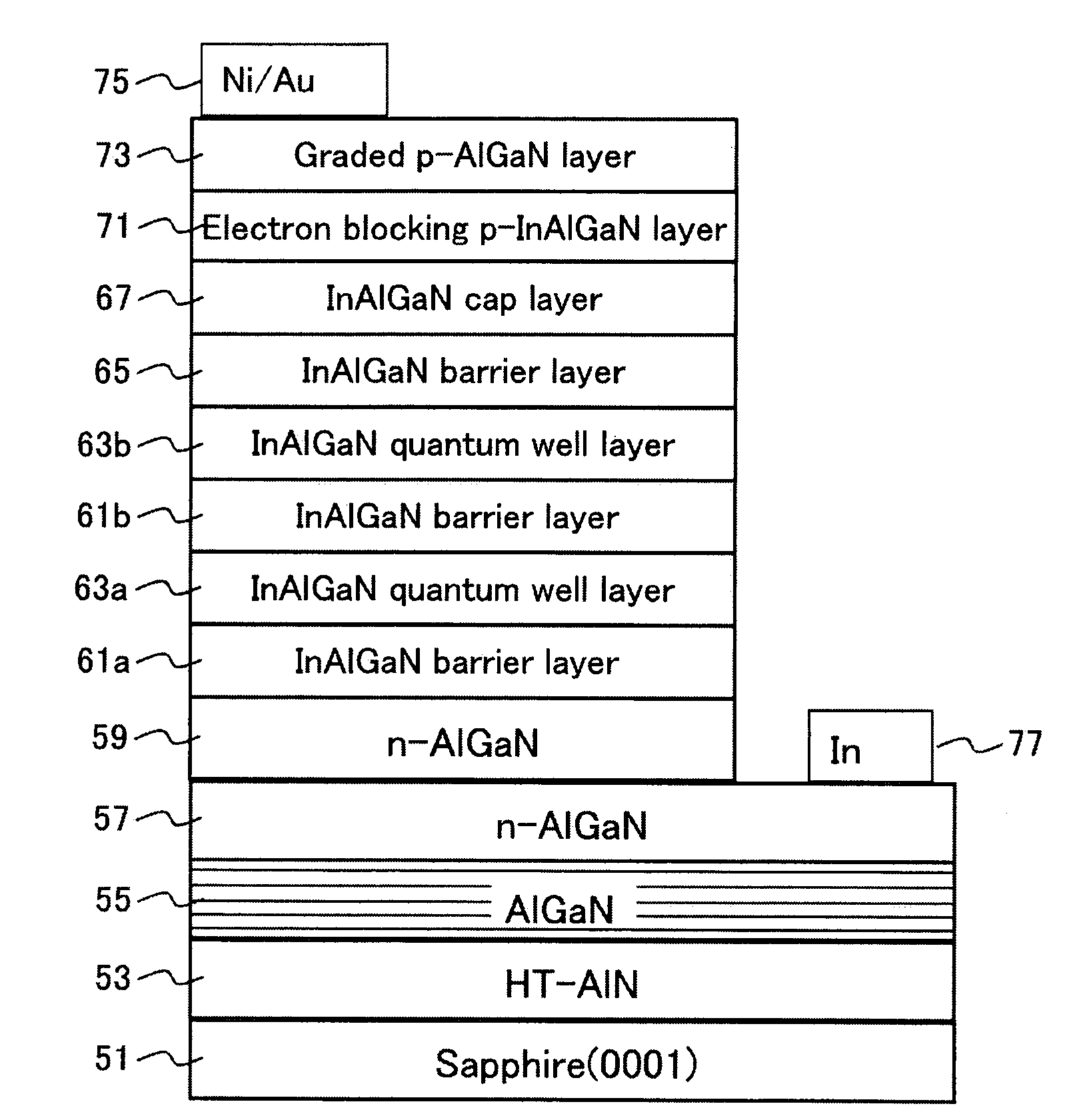

[0034]In the following, an optical semiconductor device and a manufacturing method therefor according to an embodiment of the present invention will be described with reference to the drawings. FIG. 1 is a cross-sectional view showing an atomic structure composed of group III atoms and group V atoms formed on a sapphire substrate. As shown in FIG. 1, a pulsed-supplied TMAl layer is built into a sample h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com