Fabric Care Compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

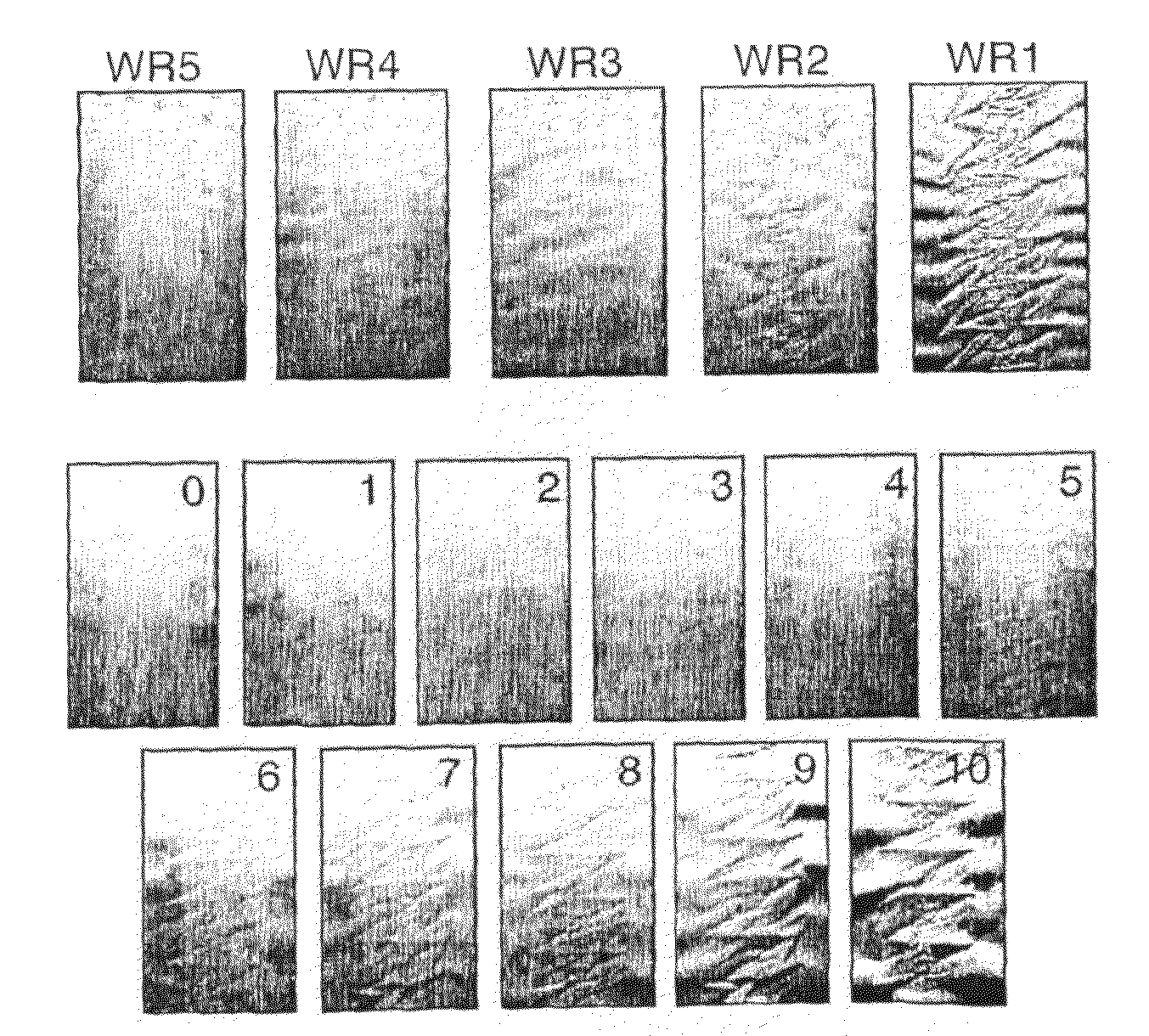

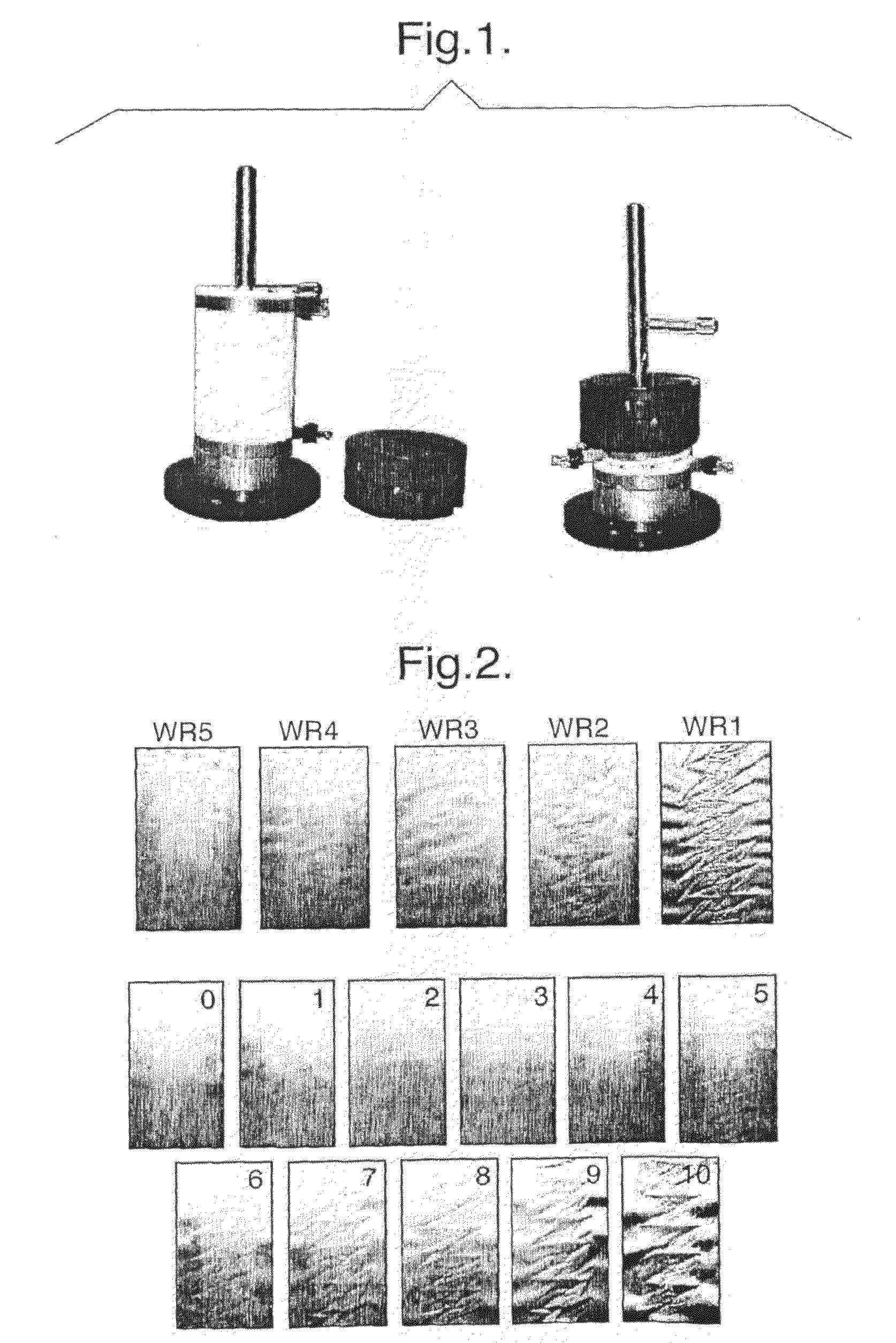

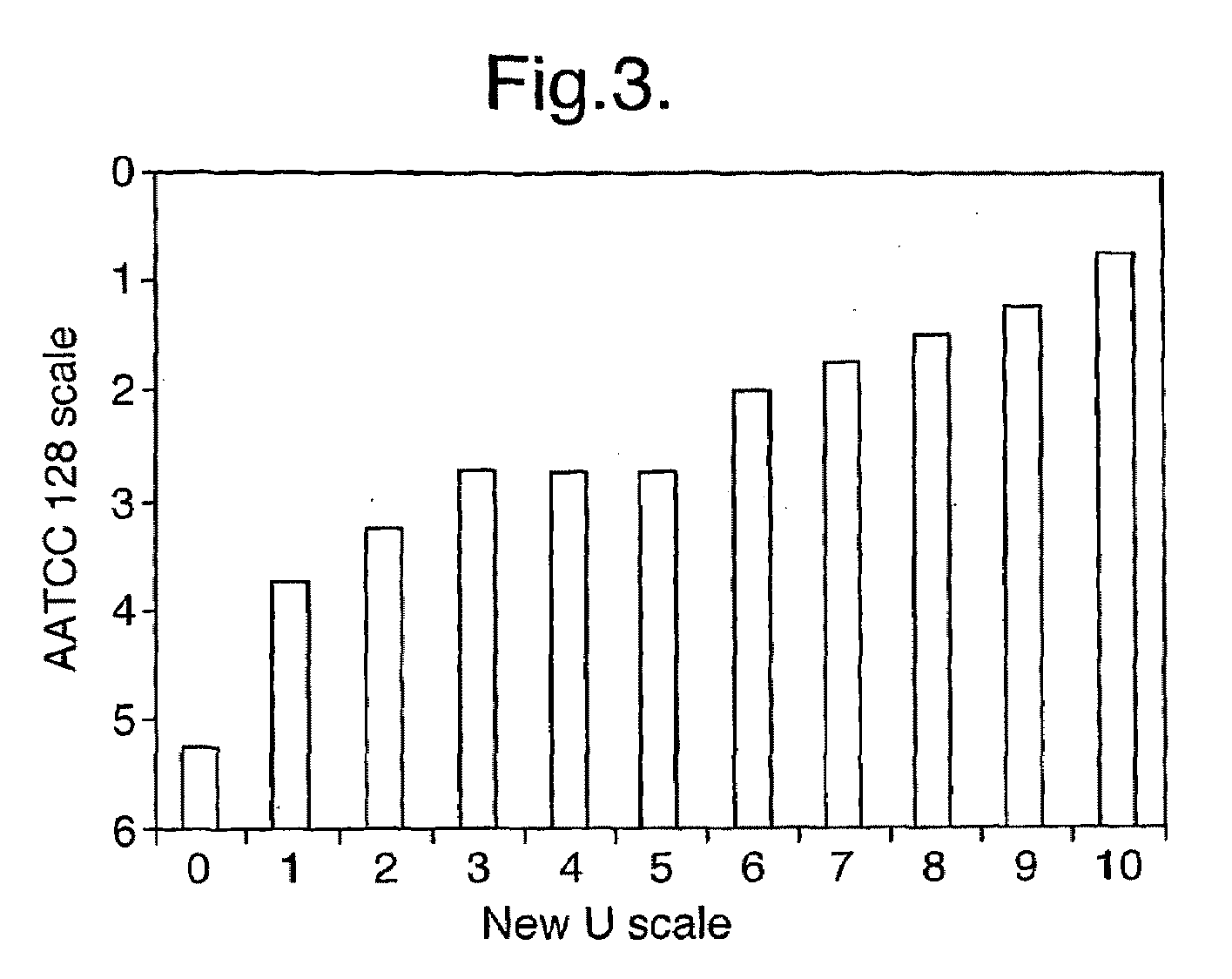

Image

Examples

examples

[0116]Tables 1 and 2 identify the nature of the lubricant and particulate phases used.

TABLE 1The physical properties of silicone emulsions (lubricants) tested.dropletoilsize / viscosity / chemistryemulsifiernmmPas sDC2-8663linearNonionic503500(DowaminosiliconeCorning)DC2-8177linearNonionic5012000(DowaminosiliconeCorning)DC1652linear pdmsNonionic700350(DowCorning)HMW2220linear pdms -Nonionic5001.2 M(DowextremelyCorning)high MWpolymerDC1716PDMS microCationicunknownunknown(DowemulsionCorning)CT208ElinearNonionicunknownunknown(Wacker)aminosilicone

TABLE 2Physical properties of some of the colloidalsilica dispersions tested.particleSilicasize / content / Trade namechargenmwt %Ciba 820 (Ciba)(+)2211Ludox CL-P silica(+)2230(Grace)Ludox TM40(−)2250(Grace)Ciba 911 (Ciba)(+)22?Ciba 1143 (Ciba)(−)??Ludox SP532-10519(+)5040(Grace Davison)

[0117]Table 3 shows the effect of lubrication treatment on its own. Using silicone oils or most other lubricants provide little or no in-wear wrinkle benefit as the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com