Auto-returning assembly with mechanical damper

a technology of mechanical damper and auto-returning assembly, which is applied in the direction of drawers, furniture parts, domestic applications, etc., can solve the problems of hazard to people walking past, damage to furniture, damage to drawers, and any fragile contents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

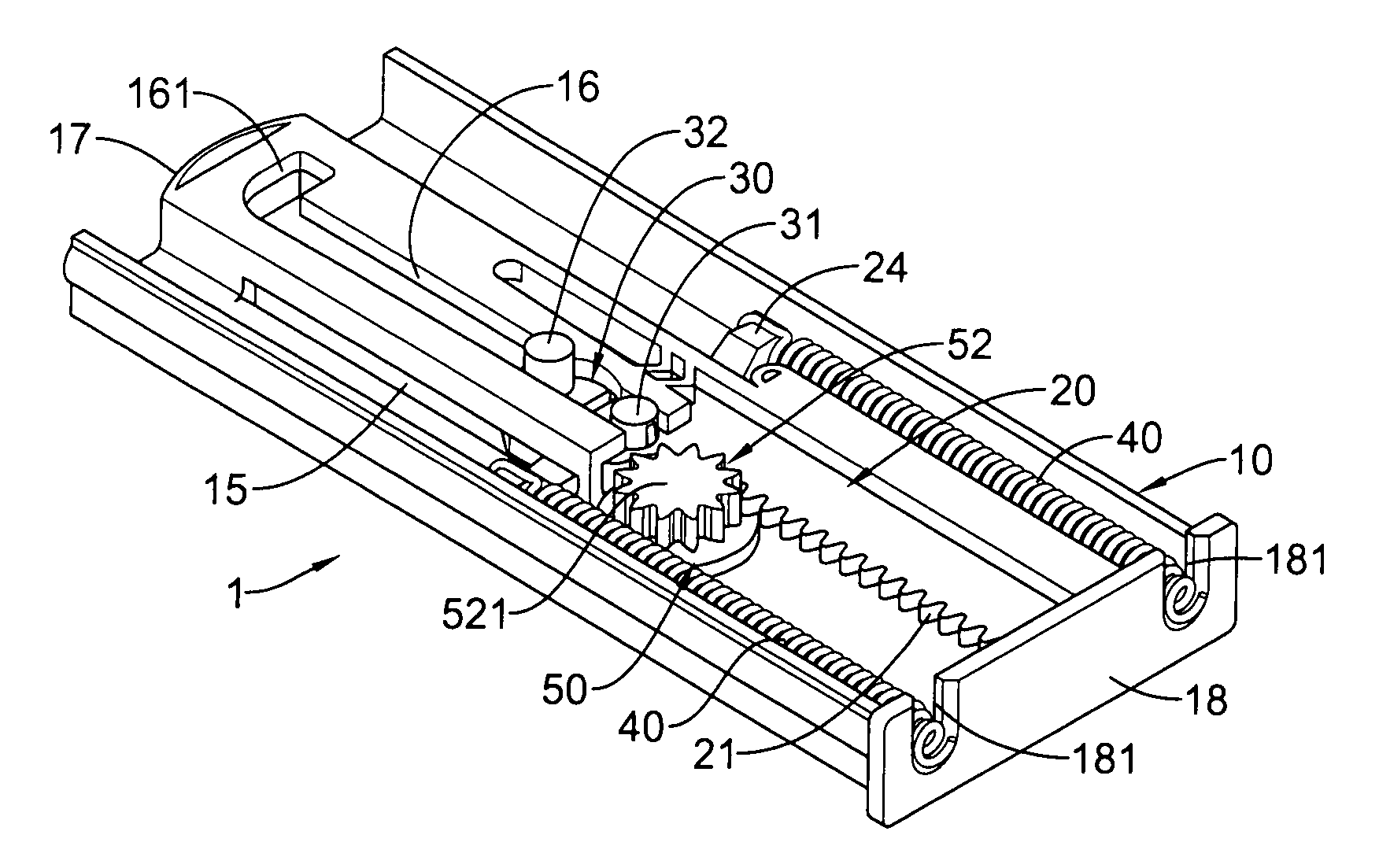

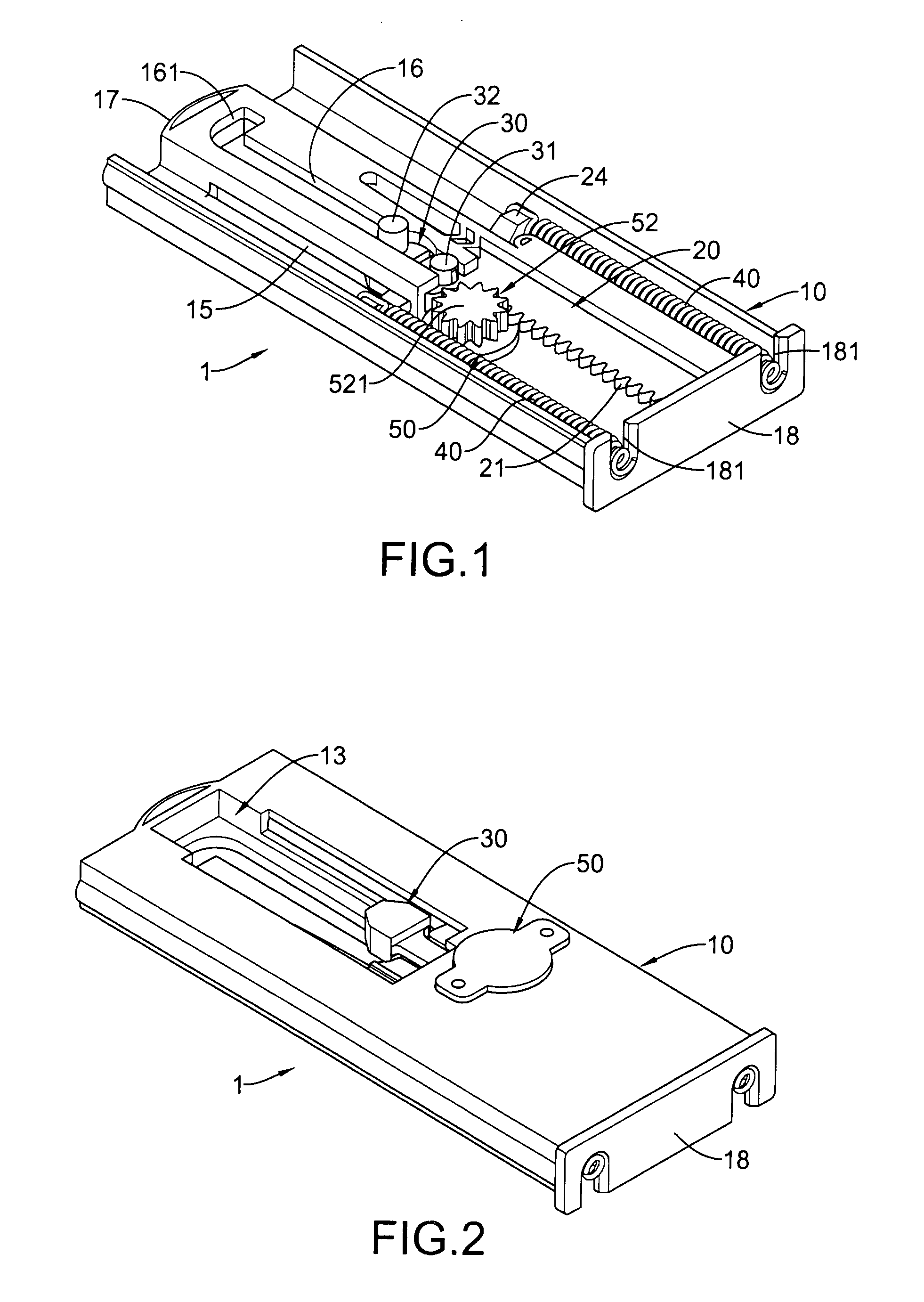

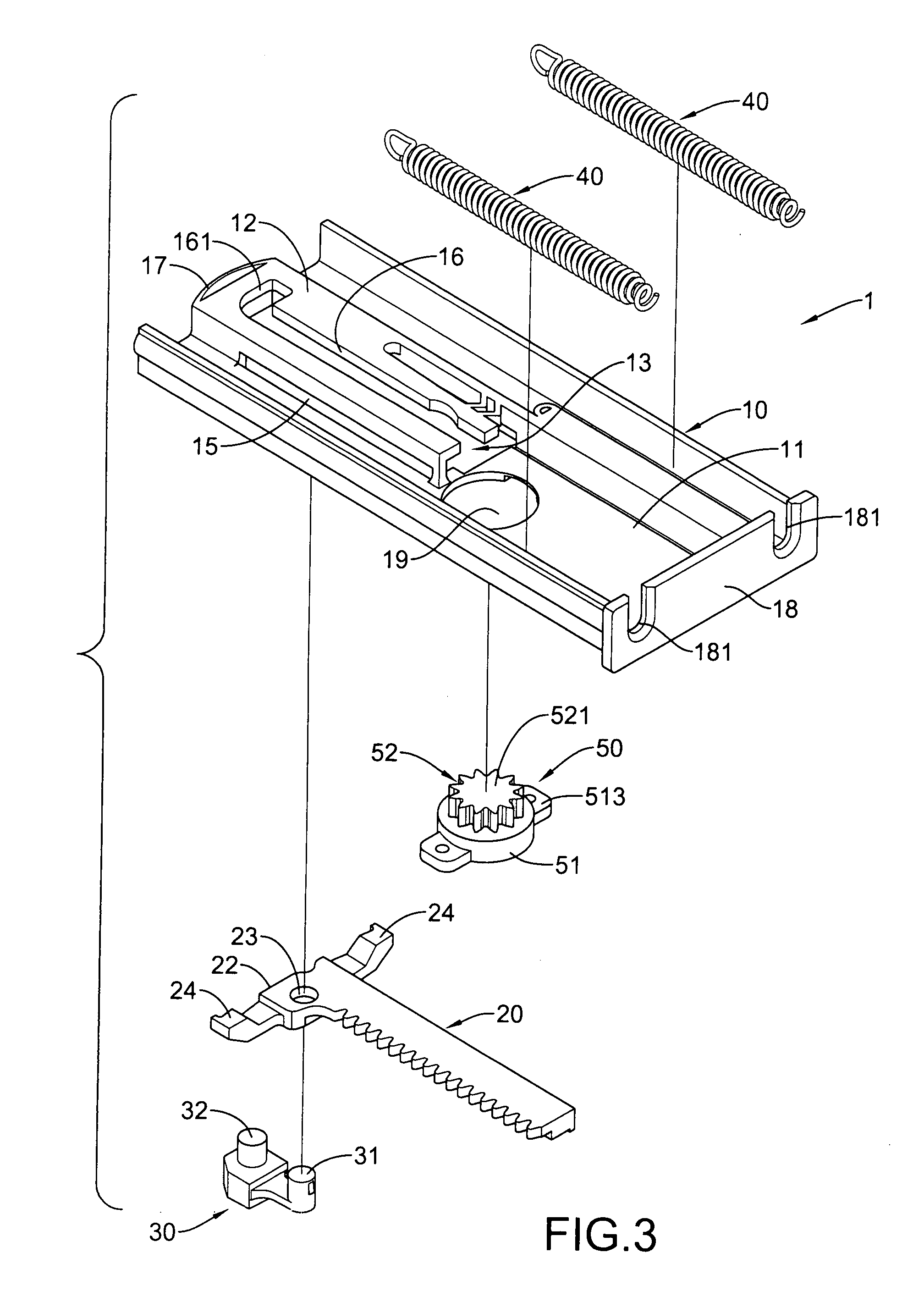

[0026]With reference to FIGS. 1 to 4, an auto-returning assembly with mechanical damper (1) in accordance with the present invention comprises a body (10), a rack (20), a locking protrusion (30), at least one springs (40) and a damper (50).

[0027]The body (10) may be a container and has a base (11), a guiding mount (12), an optional protecting bar (17), an optional connecting panel (18) and an optional damper mount (19).

[0028]The base (11) has a front end, a rear end and a recess. The recess is defined in the base (1) between the front end and the rear end. The guiding mount (12) is formed on and protrudes from the base (11) near the front end and has a front end, a rear end, two sidewalls, a top face, an opening (13), two optional channels (15) and a guide slot (16). The opening (13) is formed in rear end of the guiding mount (12). The channels (15) are respectively formed through the sidewalls of the guiding mount (12). The guide slot (16) is formed through the top face of the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com