Modular coiled tubing and sectional pipe drilling rig

a drilling rig and module technology, applied in drilling machines and methods, surveying, core removal, etc., can solve the problems of complicated moving, limited drilling process, and need to transport extremely heavy equipment to and from the drilling site, and achieve convenient movement, reasonable weight, and easy assembly and disassembly on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

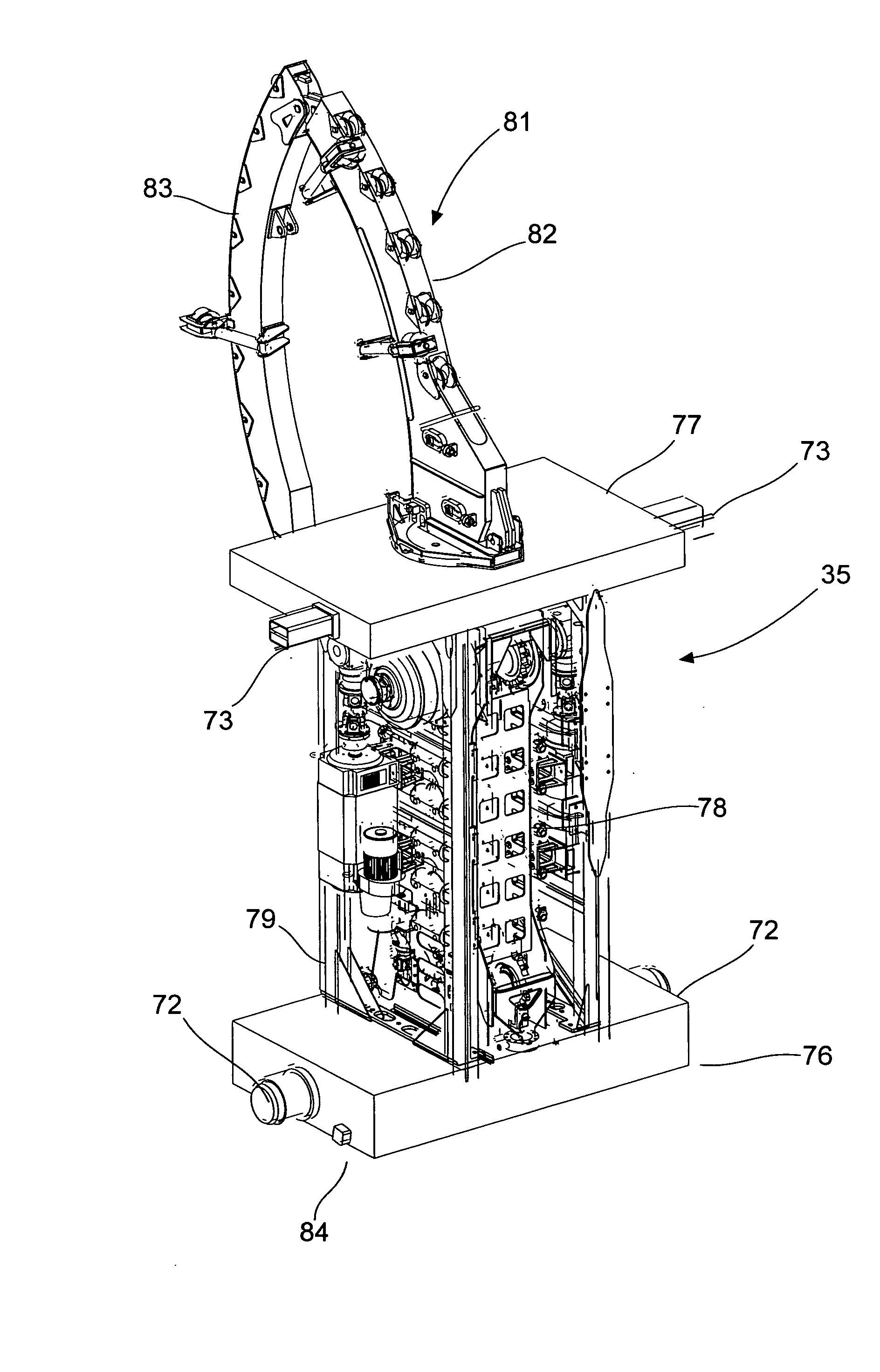

[0033]Referring first briefly to FIG. 22, there is shown a complete set up at a drilling site of rig 30 of the present invention in an operating mode and incorporating the present invention. The rig 30 includes an overall substructure or base component 31 on which there is mounted a separate drawwork / mast module, hereinafter referred to as a mast component 52. On the mast component 52 there is mounted an injector carrier 32. The mast component 52 includes an upright mast 33 which is provided with a top drive apparatus 34, the mast component being adapted to support an injector component 35 during a coiled tubing operation. Another separate module or transport component 36 carries a reel 37 which furthers supplies coiled tubing 38 during a drilling operation, or receives the coiled tubing during its withdrawal from a well.

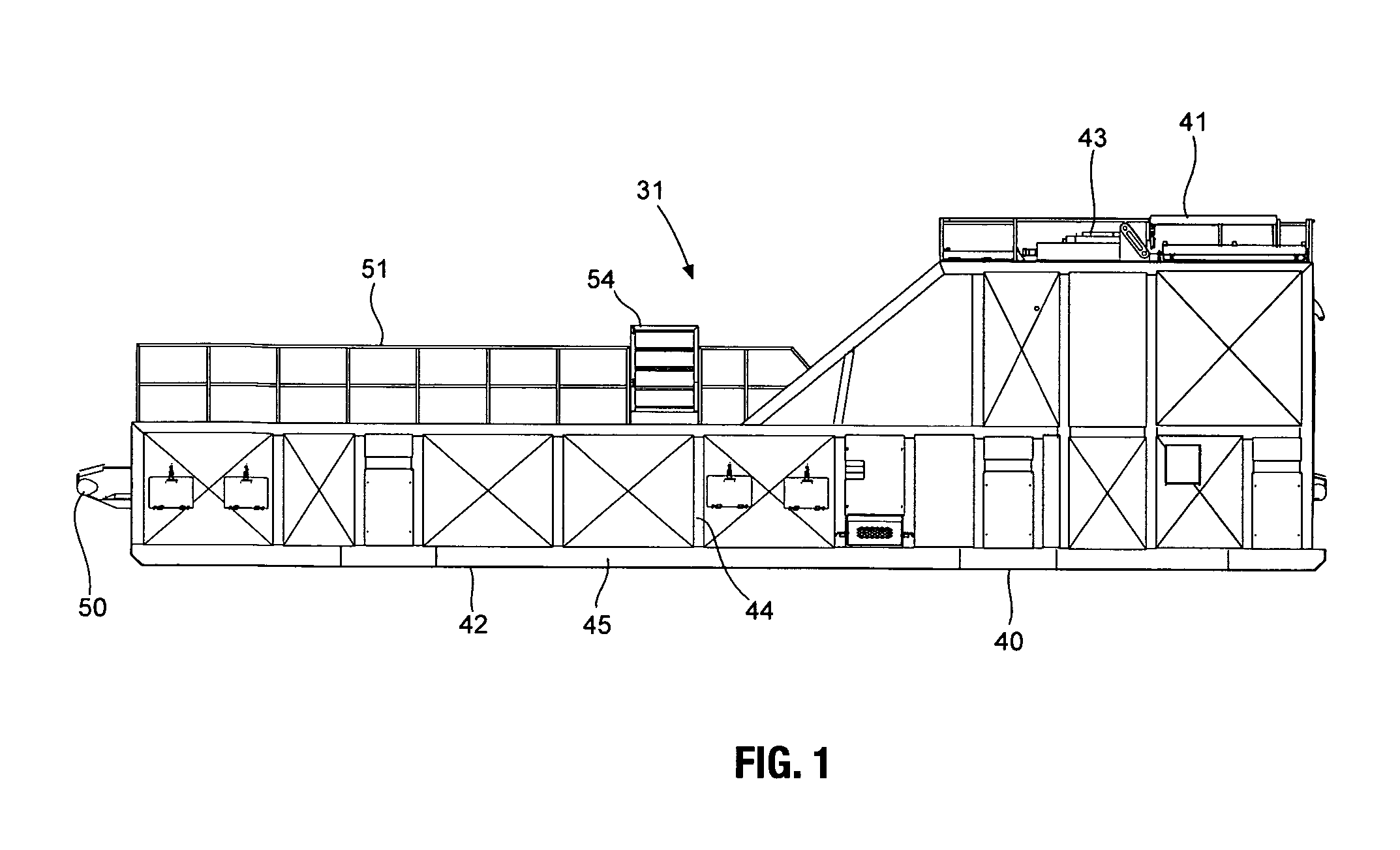

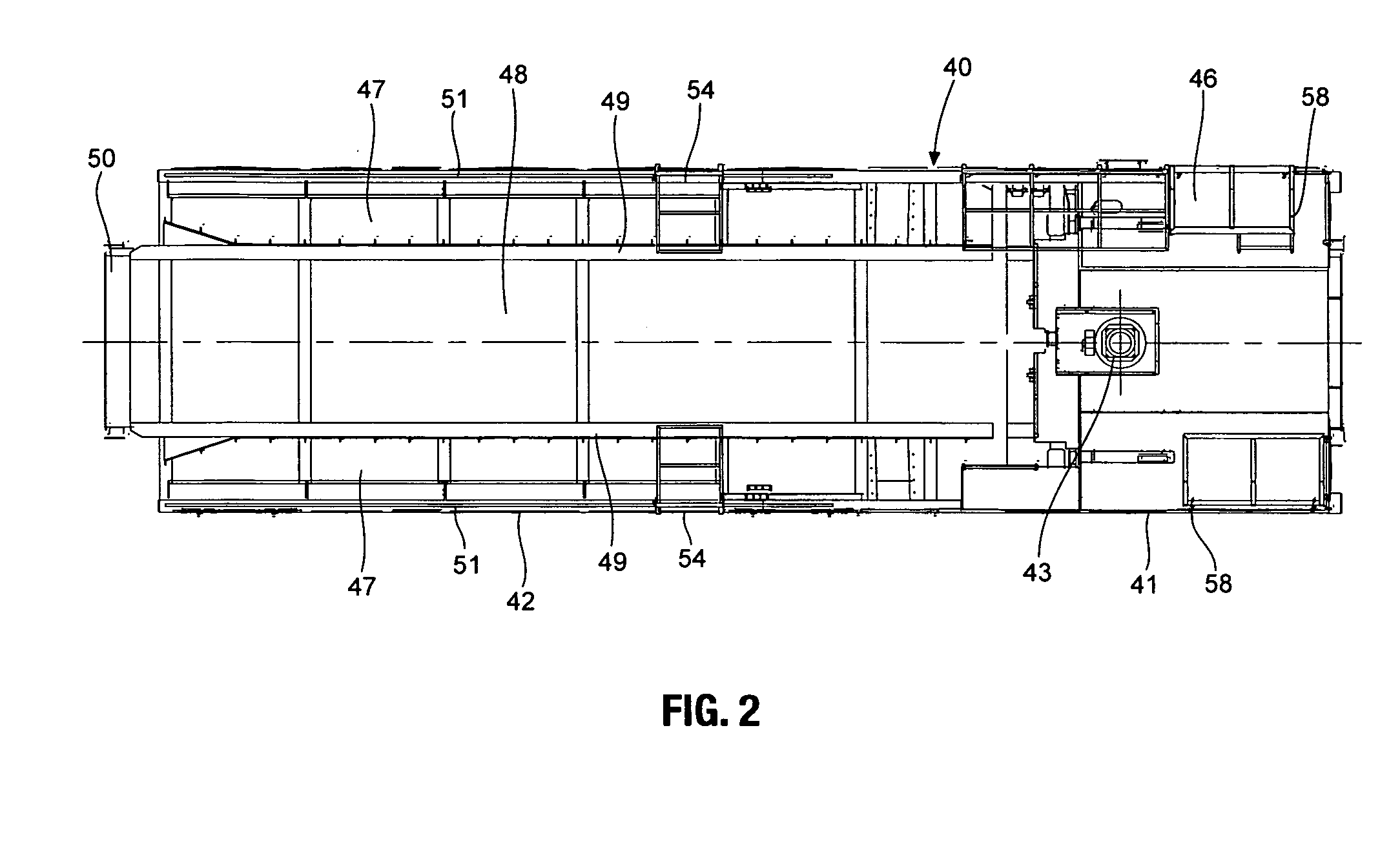

[0034]In an operatively assembled form in FIG. 1, there is shown the first module or base component 31 which is in the form of a completely separable substructure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com