Dual direction exercise treadmill for simulating a dragging or pulling action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

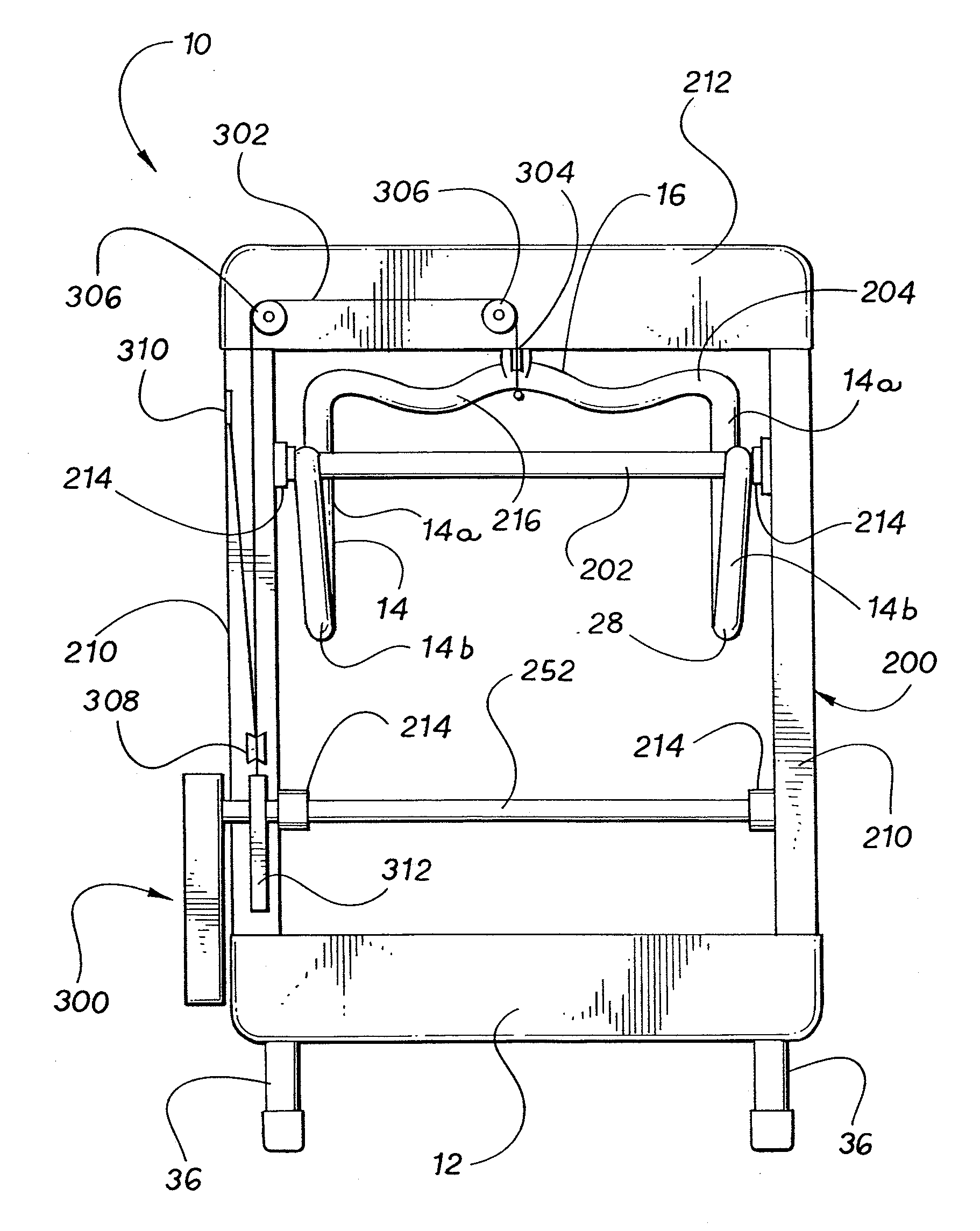

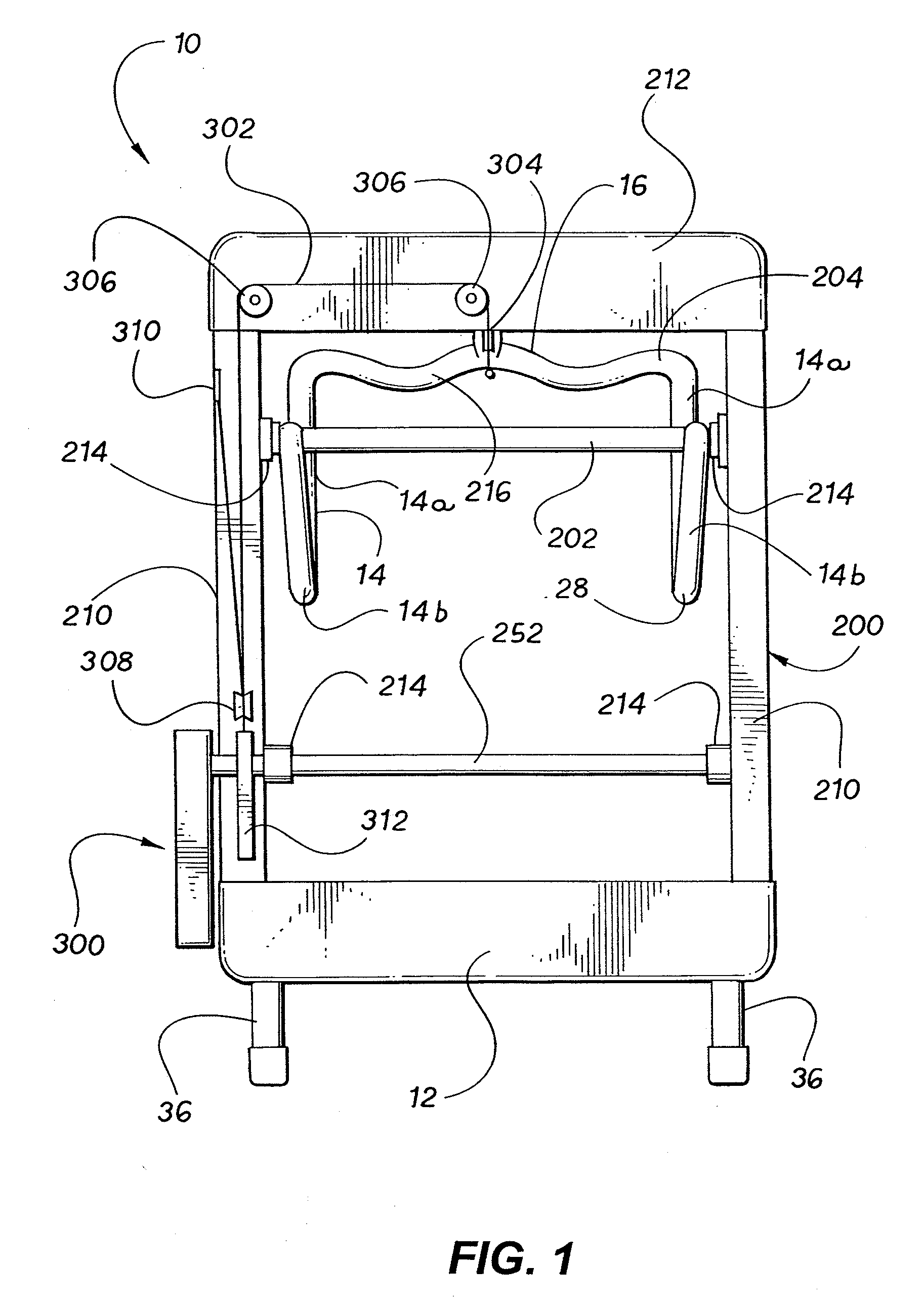

[0074]FIG. 5 is a side view of an embodiment of the moment arm weight resistance mechanism in the resting position. FIG. 6 is a side view of an embodiment of the moment arm weight resistance mechanism in a resistance position. FIG. 7 is a top view of an embodiment of the moment arm weight resistance mechanism for the invention. FIG. 8 is a side view of the embodiment of the moment arm weight resistance mechanism shown in FIG. 7. FIG. 9 is a side view of an alternate embodiment of a moment arm weight resistance mechanism for the invention. FIG. 10 is a sectional side view of the moment arm weight resistance mechanism shown in FIG. 3 in larger detail.

[0075]FIG. 11 is a sectional side view of a representative weight and weight adjusting drive that can be used with the invention. FIG. 12 is a side view of one internal pulley and cable configuration between the resistance arm and the moment arm mechanism. FIG. 13 is a view of a representative control console and hand controller for the i...

first embodiment

[0076]FIG. 15 is a side view, partly in section, of one embodiment of the invention operating in reverse dragging / pulling mode in an inclined position, showing a moment arm weight resistance mechanism and a hand grip or hand grip controller operatively attached to the weight resistance mechanism only via a flexible cable so as to have a multi-directional range of motion, without resistance arm sections or linkages. FIG. 16 is a top view of an embodiment of the invention having a movable hand grip or hand grip controller operatively connected to the weight resistance mechanism and a fixed control console, illustrating the distinction between the movable hand grip controller and the fixed or unmovable console control. FIG. 17 is a top view of an embodiment of the invention showing controller features both on the movable resistance arm and the fixed console controller.

[0077]FIG. 18 is a side view, partly in section, of an alternate pneumatic or hydraulic weight resistance mechanism in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com