Underwater ultrasonic thawing apparatus

a technology of ultrasonic thawing and underwater, which is applied in water heaters, waterways, constructions, etc., can solve the problems of moisture vaporization on the surface of the stuff, the thawing speed of the core portion, and the degradation of the freshness of the food in a bad environment, so as to prevent the degradation of not only the freshness of the stuff, the effect of short thawing time and preventing the degradation of the cor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

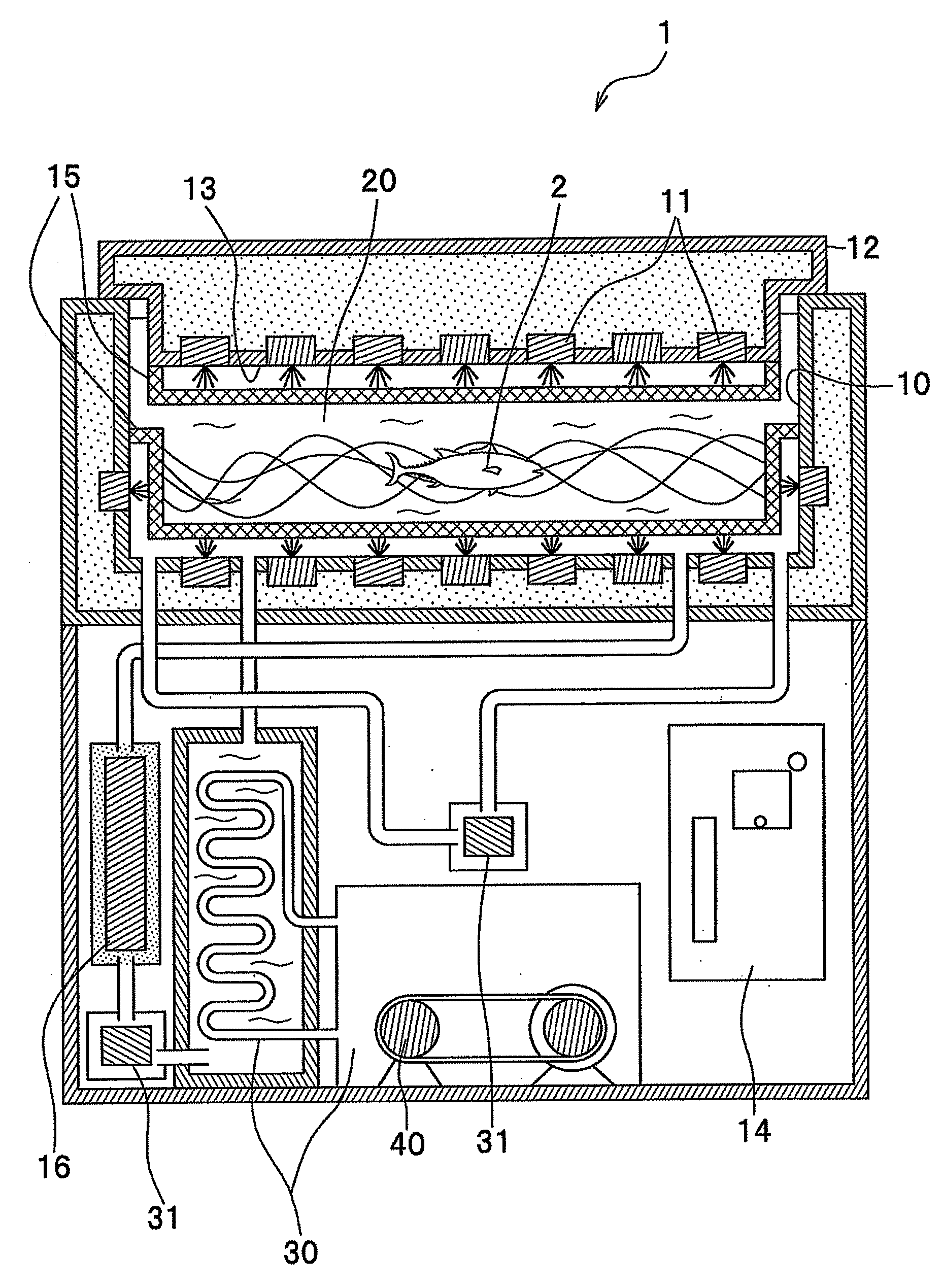

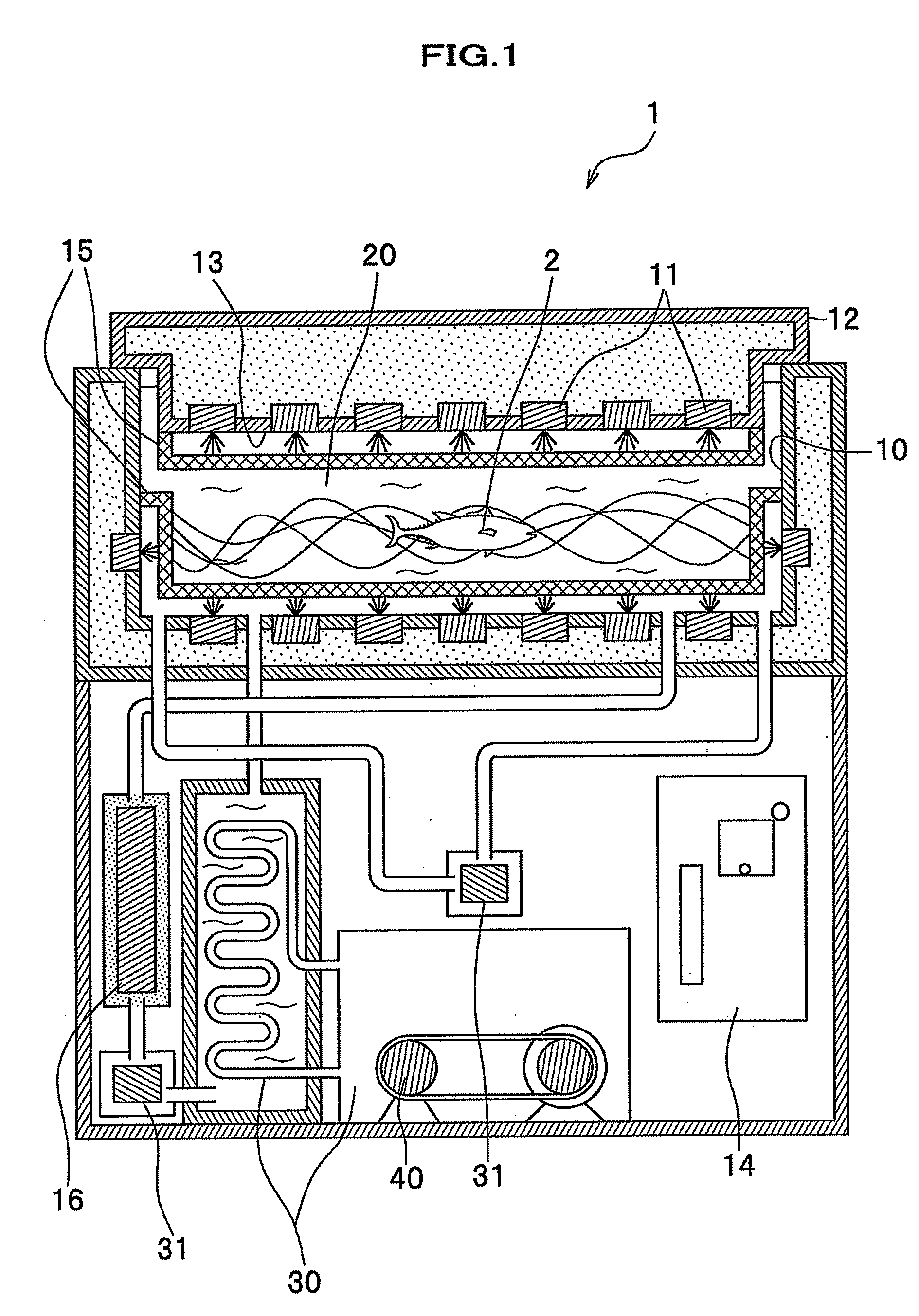

[0040]Next will be described an underwater ultrasonic thawing apparatus 1 relating to an embodiment of the present invention.

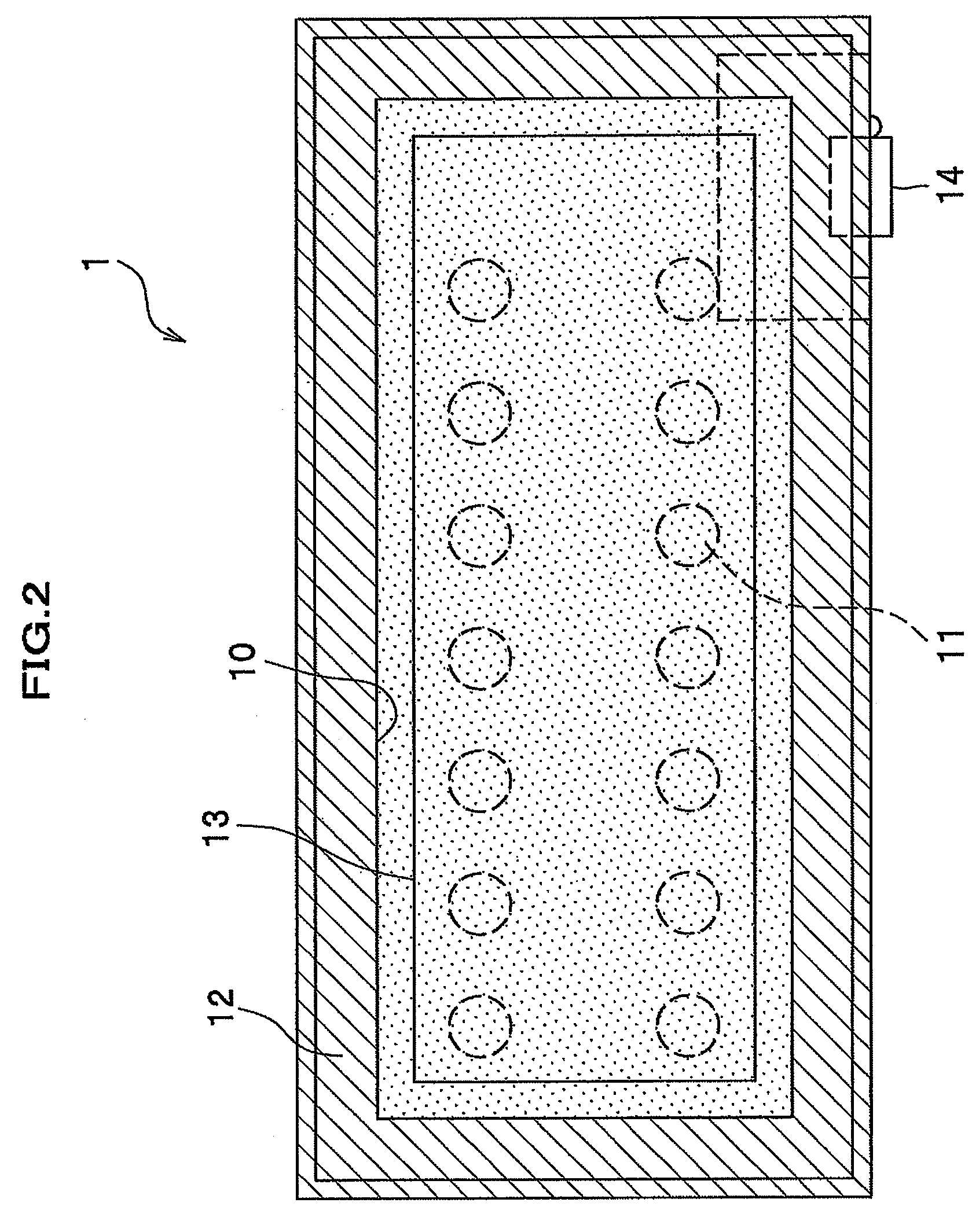

[0041]With respect to the underwater ultrasonic thawing apparatus 1 shown in FIG. 1 relating to the embodiment, a thawing treatment tank 10 including underwater ultrasonic vibrators 11 provided on inner faces thereof and a thawing treatment tank lid 12 configured to close an opening of the tank 10 are attached to be freely opened and closed. Furthermore, the underwater ultrasonic thawing apparatus 1 comprises a controller 14 configured to control an operation of the underwater ultrasonic vibrators 11, a temperature adjuster 30 configured to adjust a temperature of thawing treatment water 20 filled in the thawing treatment tank 10, and circulation pumps 31 configured to circulate the thawing treatment water 20 adjusted to a predetermined temperature by the adjuster 30. Furthermore, the underwater ultrasonic thawing apparatus 1 comprises mesh plates 15 as a sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com