Refrigerant evaporator

a technology of refrigerant evaporator and liquid refrigerant, which is applied in the direction of refrigerating machines, stationary conduit assemblies, lighting and heating apparatus, etc., can solve the problems of difficult to clear the stagnation of liquid refrigerant, and liquid refrigerant is likely to stagnate in the core, so as to reduce heat capacity, suppress the decrease of heat exchange efficiency, and increase the pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Exemplary embodiments of the present invention will now be described with reference to the accompanying drawings.

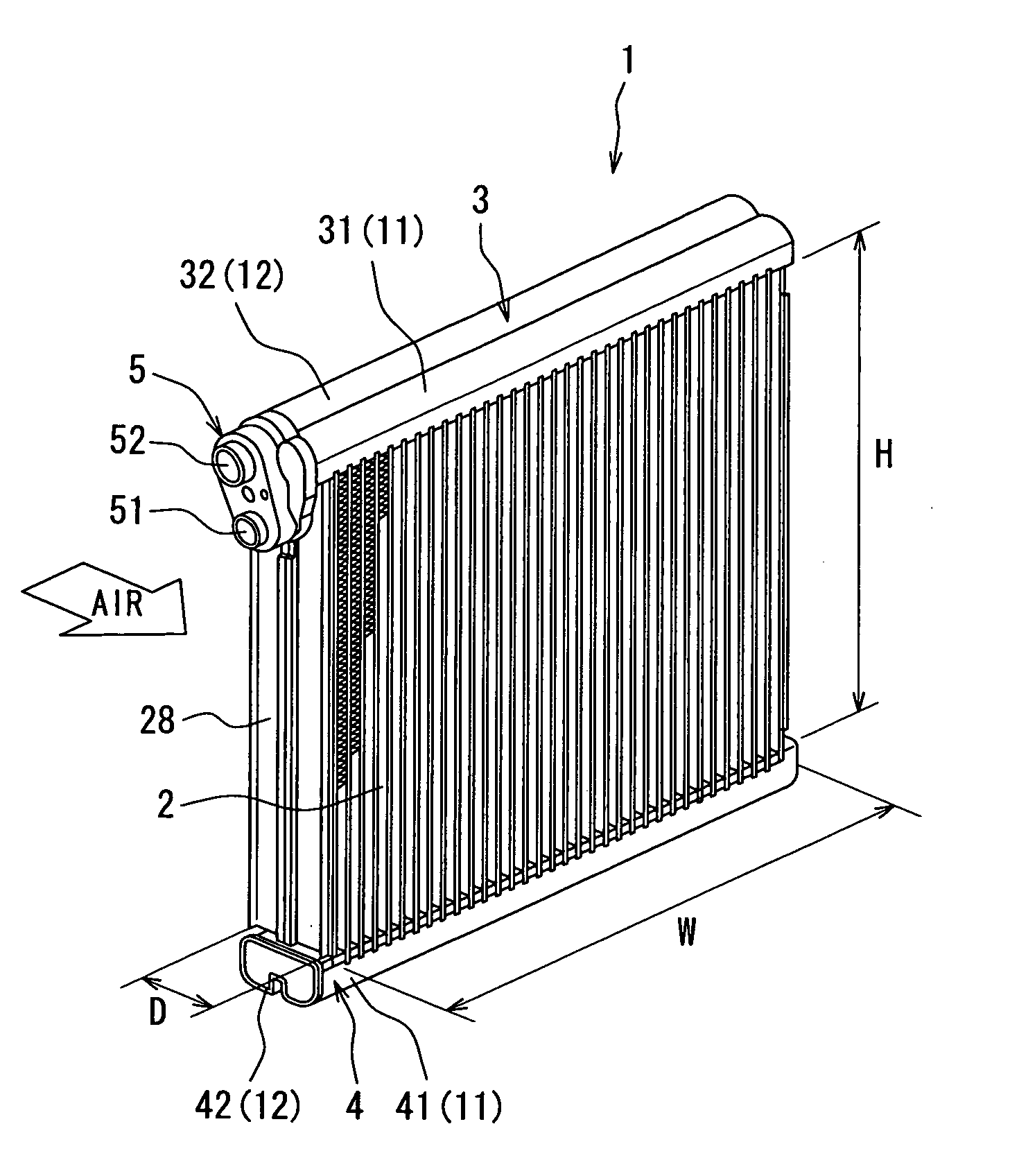

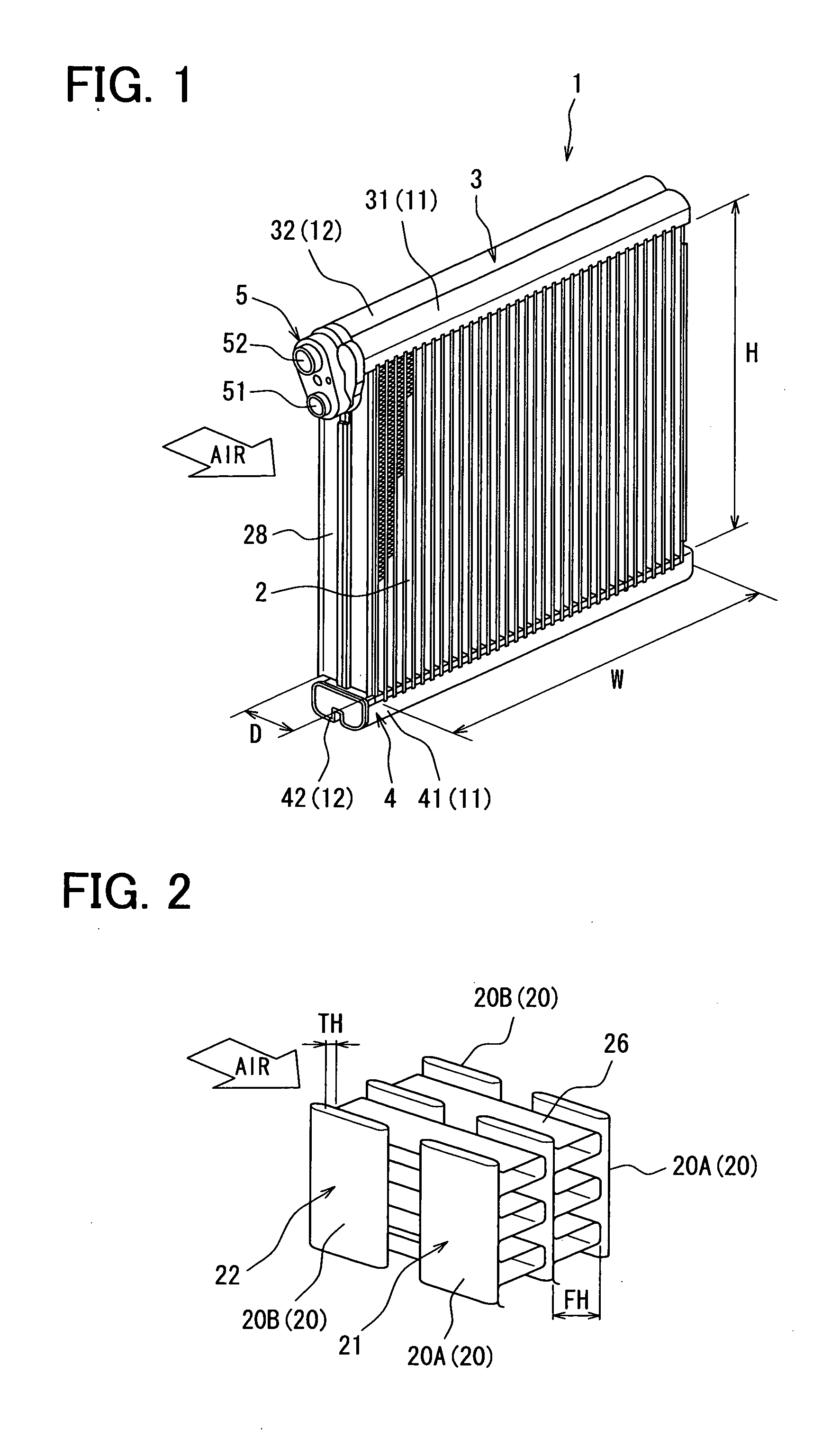

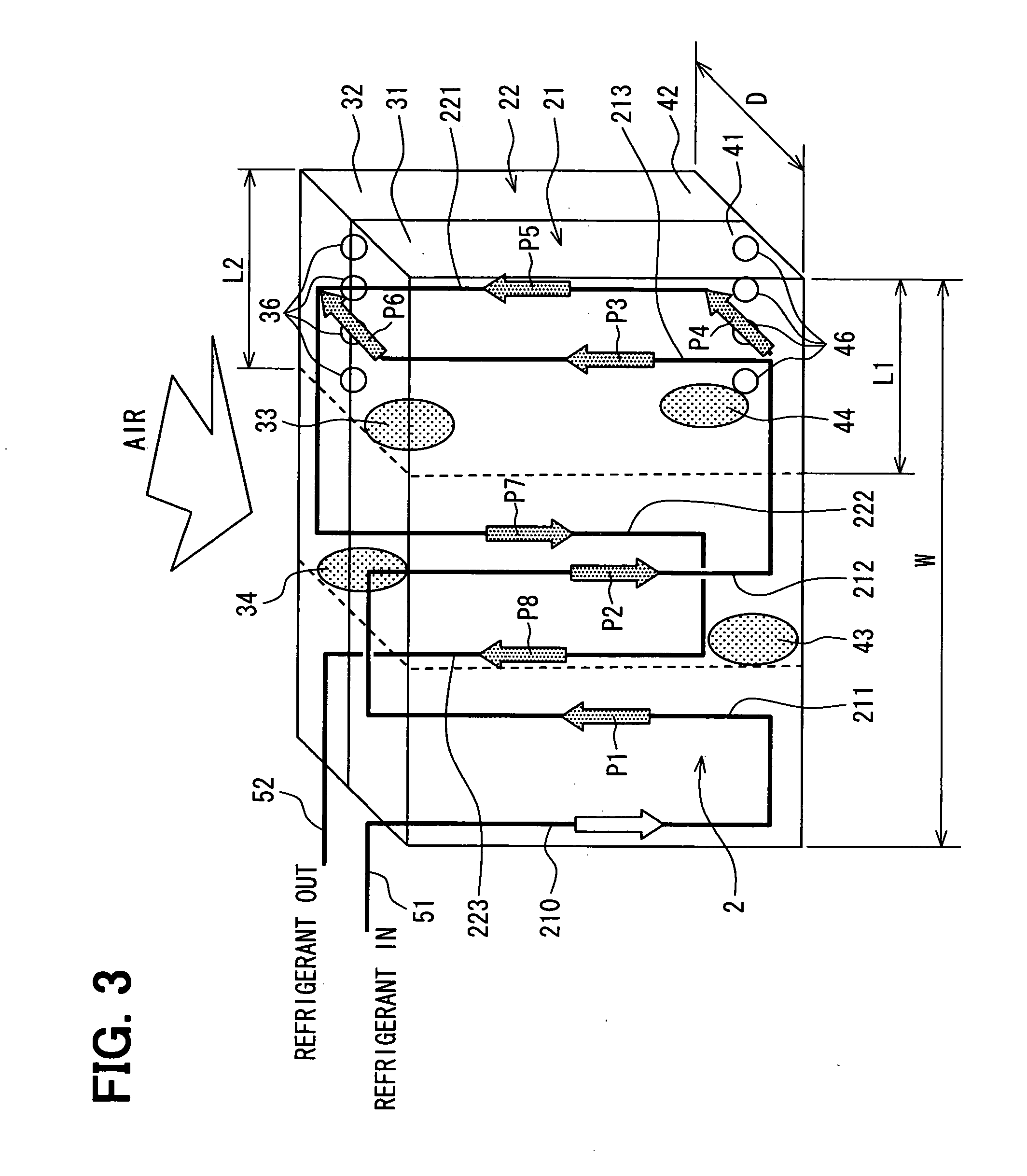

[0024]FIGS. 1 to 3 show an embodiment of the present invention. In the present embodiment, a refrigerant evaporator 1 (hereinafter, simply referred to as the evaporator 1) is, for example, employed to a refrigerant cycle apparatus for a vehicular air conditioner. In the refrigerant cycle apparatus, a refrigerant is compressed into a high temperature, high pressure refrigerant by a refrigerant compressor. The high temperature, high pressure refrigerant is cooled through a radiator, and is decompressed into a low temperature, low pressure refrigerant by a decompressing device. The low temperature, low pressure refrigerant is evaporated in the evaporator 1. In the present embodiment, the refrigerant is, for example, R134a. The radiator serves as a condenser for condensing the refrigerant discharged from the refrigerant compressor.

[0025]The evaporator 1 generally includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com