Method of Manufacturing Packaging Comprising Pharmaceutical Products

a manufacturing method and technology for pharmaceutical products, applied in the direction of packaging/bundling articles, medical devices, packaged goods, etc., can solve the problems of relatively cumbersome production methods and extremely complicated overall methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

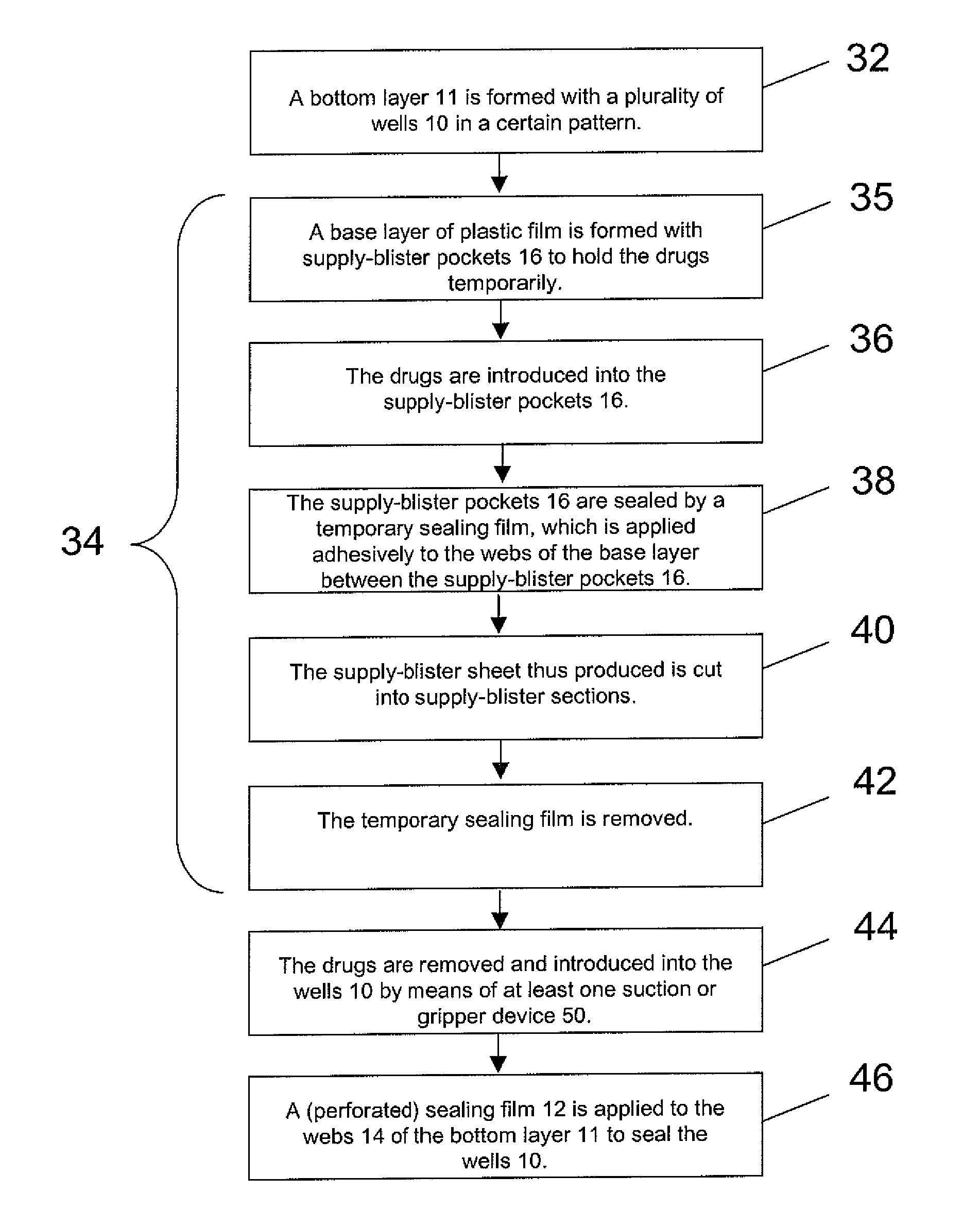

[0029]A flow chart of the inventive method for producing the multi-day package is shown in FIG. 3.

[0030]First, wells 10 to hold the drugs are formed in a bottom layer 11 (step 32). For this purpose, the bottom layer 11 is pulled from a roll, possibly heated in a heating station, and then provided with the wells 10 in a following forming station.

[0031]Then a predetermined number of different drugs are arranged (step 34) in predetermined positions at various dispensing stations of the filling station. The steps to be carried out for this purpose in the case of the embodiment according to FIG. 3 are explained in the following.

[0032]First, in step 35, a base layer of considerable size in the longitudinal and transverse directions is formed, as a result of which a large number of supply-blister pockets 16 is obtained. For this purpose, the base layer is unwound from a roll, possibly heated in a heating station, and provided with the supply-blister pockets 16 in a forming station. Then th...

second embodiment

[0040]The arrangement 34 of a predetermined number of a drug in predetermined positions at a dispensing station of the filling device can also be carried out in accordance with a second embodiment, as can be seen from FIGS. 4 and 6.

[0041]In this case, the holders of a sorting plate 56, which are arranged in correspondence with the pattern of the wells 10 in the multi-day package, are filled with drugs. The individually controlled suction or gripper devices 50 can be arranged above the sorting plate 56 in correspondence with the pattern of the holders. This is especially effective when large numbers of these drugs are to be packed into each multi-day package. The placing of the drugs onto the sorting plate 56 is preferably accomplished by means of a vibrating chute. To ensure that all of the holders of the sorting plate 56 are filled, a brushing movement with a brush device 58 is then preferably carried out, which also takes care of removing excess tablets from the sorting plate 56.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| suction | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com