Carrier member for transmitting circuits, coreless printed circuit board using the carrier member, and method of manufacturing the same

a carrier member and carrier technology, applied in the direction of printed circuit manufacturing, printed circuit aspects, conductive pattern formation, etc., can solve the problems of reducing the reliability of circuits, reducing the size and thickness of substrates, and reducing the area of circuits, so as to achieve high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the attached drawings.

[0041]Reference now should be made to the drawings, in which the same reference numerals are used throughout the different drawings to designate the same or similar components.

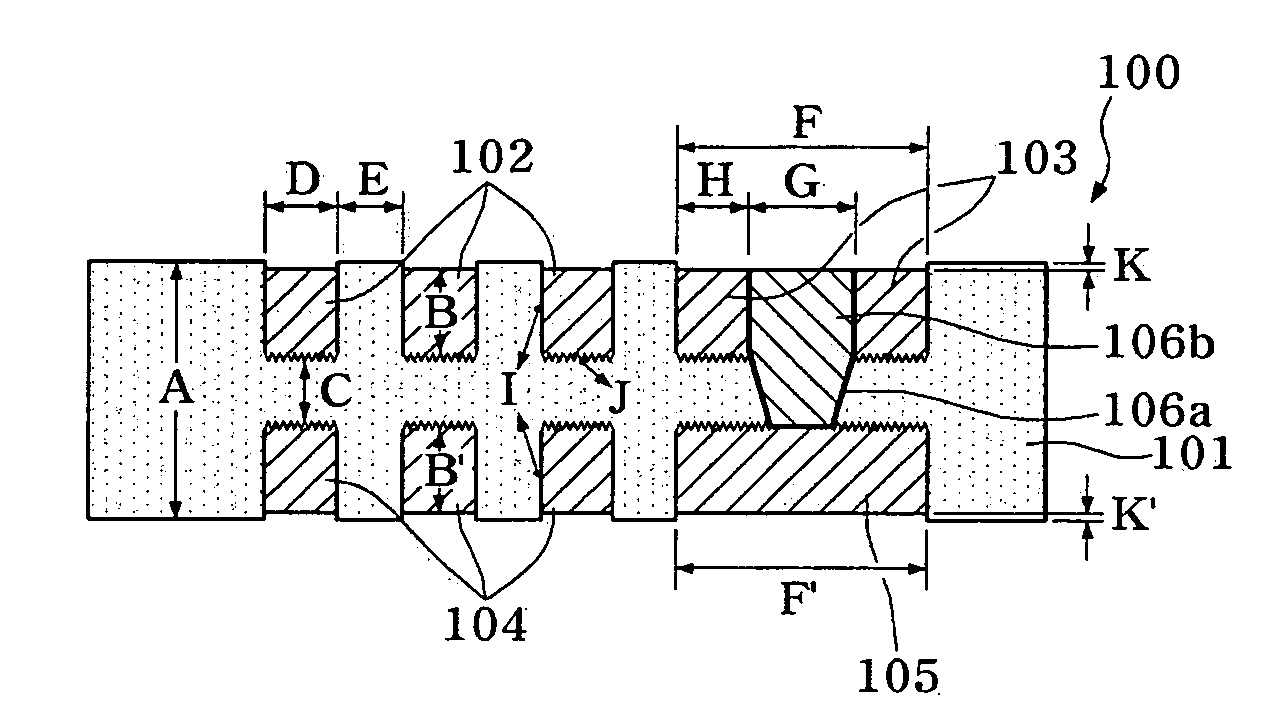

[0042]FIG. 1 is a schematic sectional view showing a structure of a coreless printed circuit board according to an embodiment of the present invention.

[0043]The coreless printed circuit board according to an embodiment of the present invention, which is a thin structure with circuits embedded in resin, can be used as a core structure of a high-density substrate.

[0044]Referring to FIG. 1, the coreless printed circuit board 100 includes a resin insulation layer 101; circuit patterns 102 and 104, including lands 103 and 105, the surfaces of which are exposed, and which are embedded in respective sides of the resin insulation layer 101; and a via 106 contacting the lands 103 and 105...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com