Device and Method for Thread Positive Feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

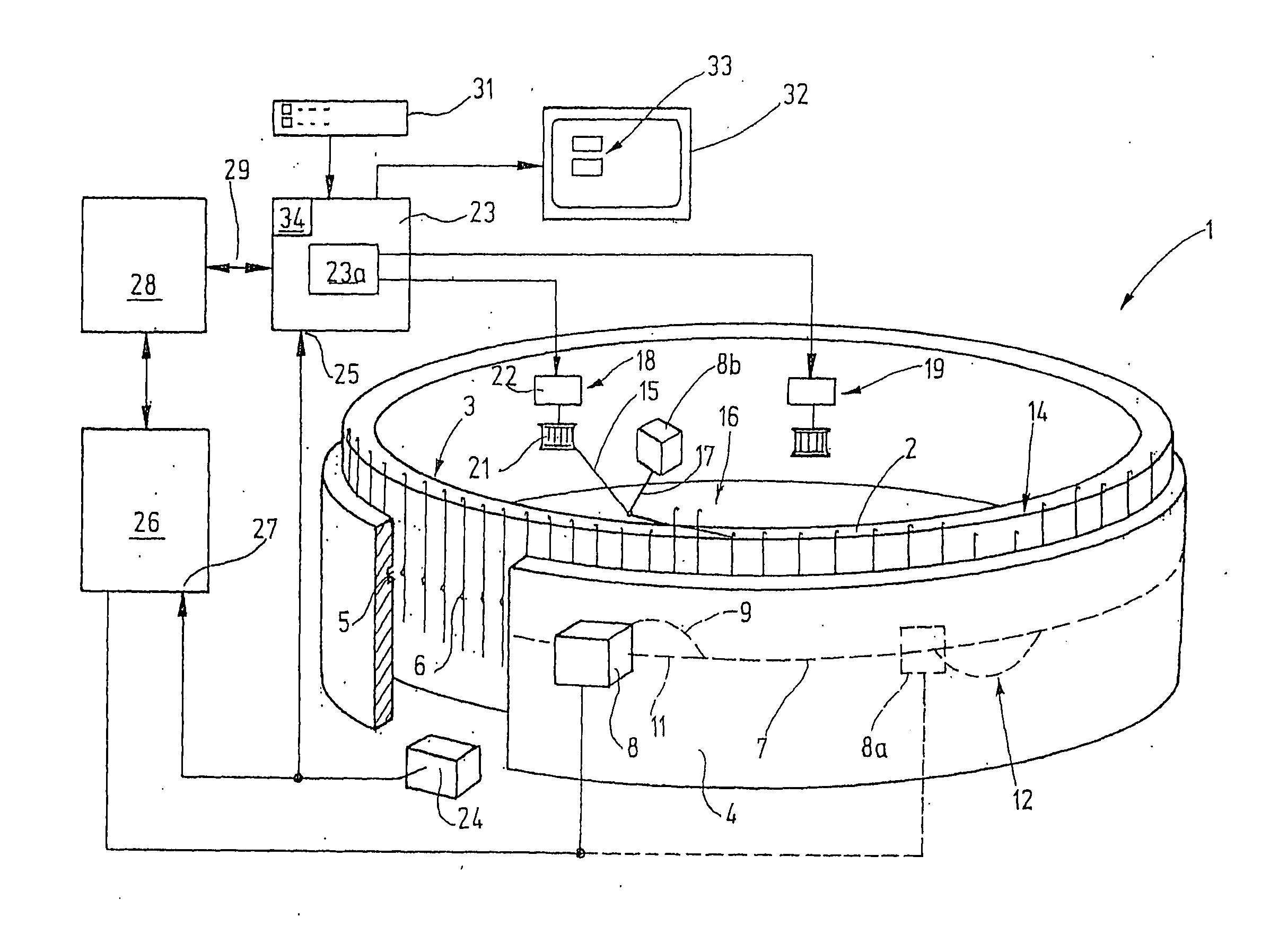

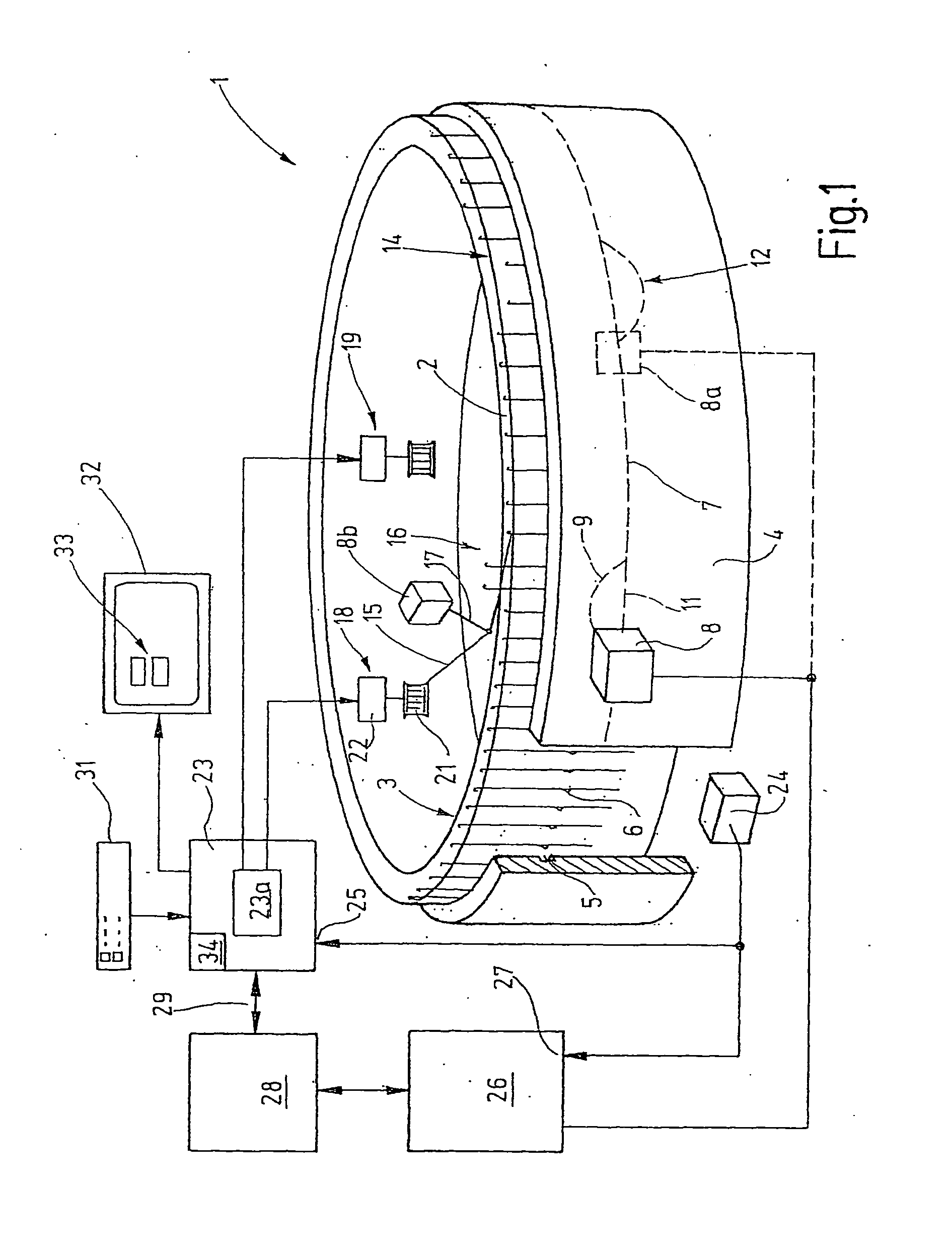

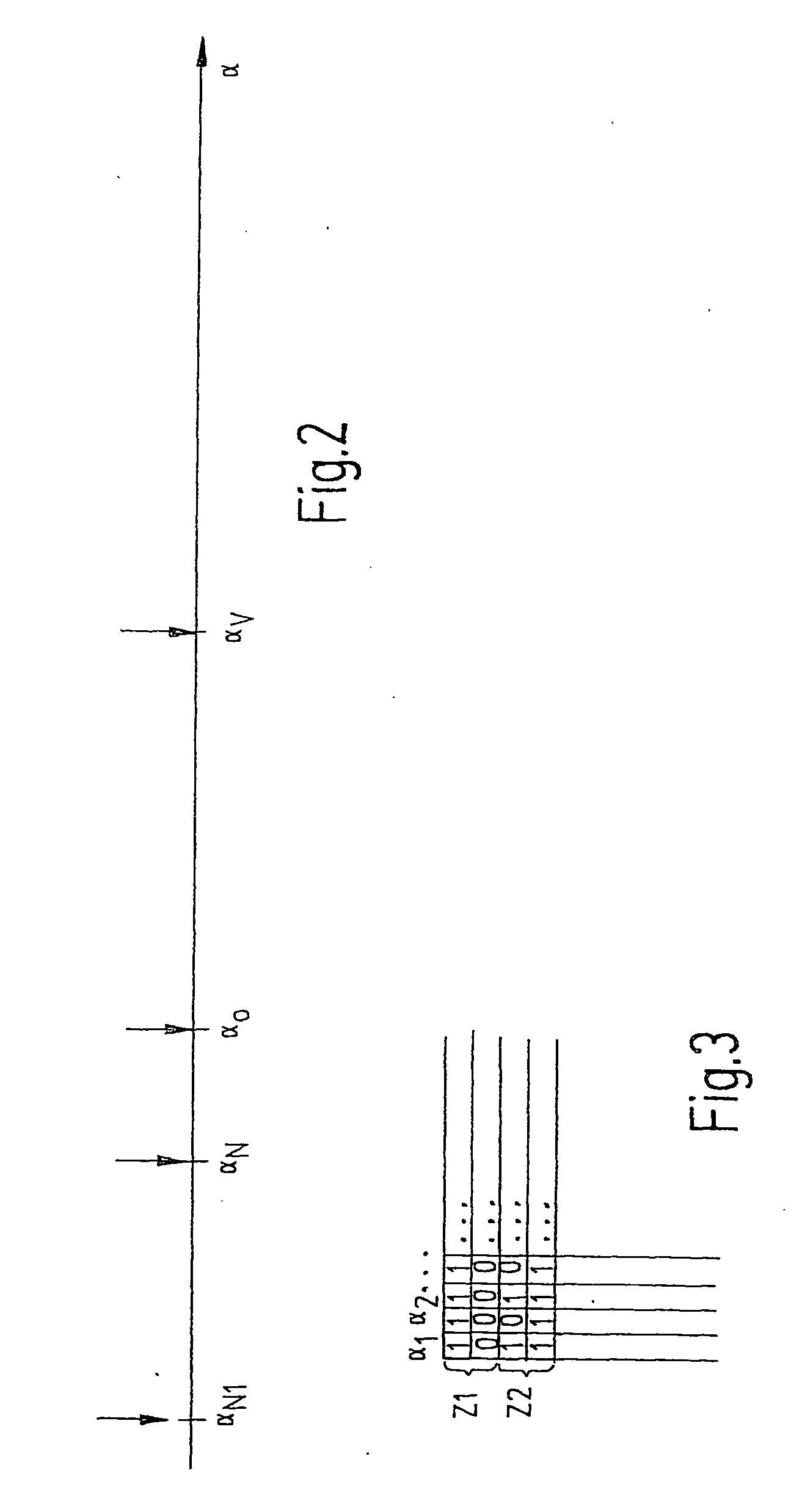

[0023]In the following description, a number of reference numbers are used to refer to specific elements in the several drawings. These reference numerals correspond to the drawing elements as follows: Knitting machine (1); Needle cylinder (2); Needles (3); Lock (4); Lock cam (5); Line (7); Switching element (8, 8a); Actuator (8b); Branches (v); Points (12); Stitching positions (14); Thread (15); Hold points (16); Thread guide (17); Thread feeding devices (18, 19); Thread feed wheel (21); Motor (22); Control device (23); Processing module (23a); Position sensor (24); Position input (25); Control unit (26); Position input (27); Pattern memory (28); Data connection (29); Input device (31); Display device (32); Input masks (33); Data memory (34); and Thread tension sensor (35).

[0024]In FIG. 1, a knitting machine 1 designed for manufacturing patterned goods is shown schematically. The knitting machine 1 has a needle cylinder 2, which is mounted so that it can rotate about a vertical axi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com