Filter device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

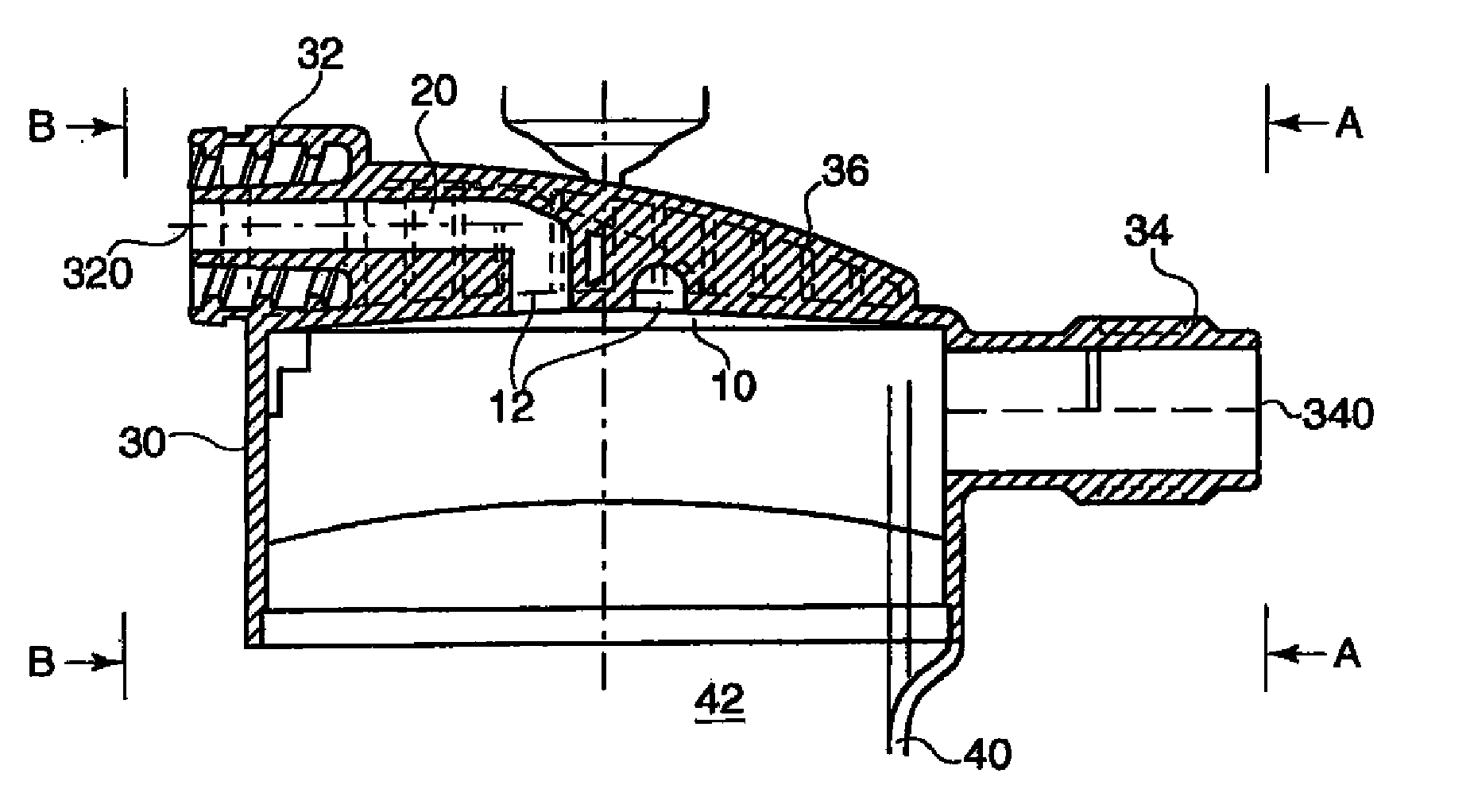

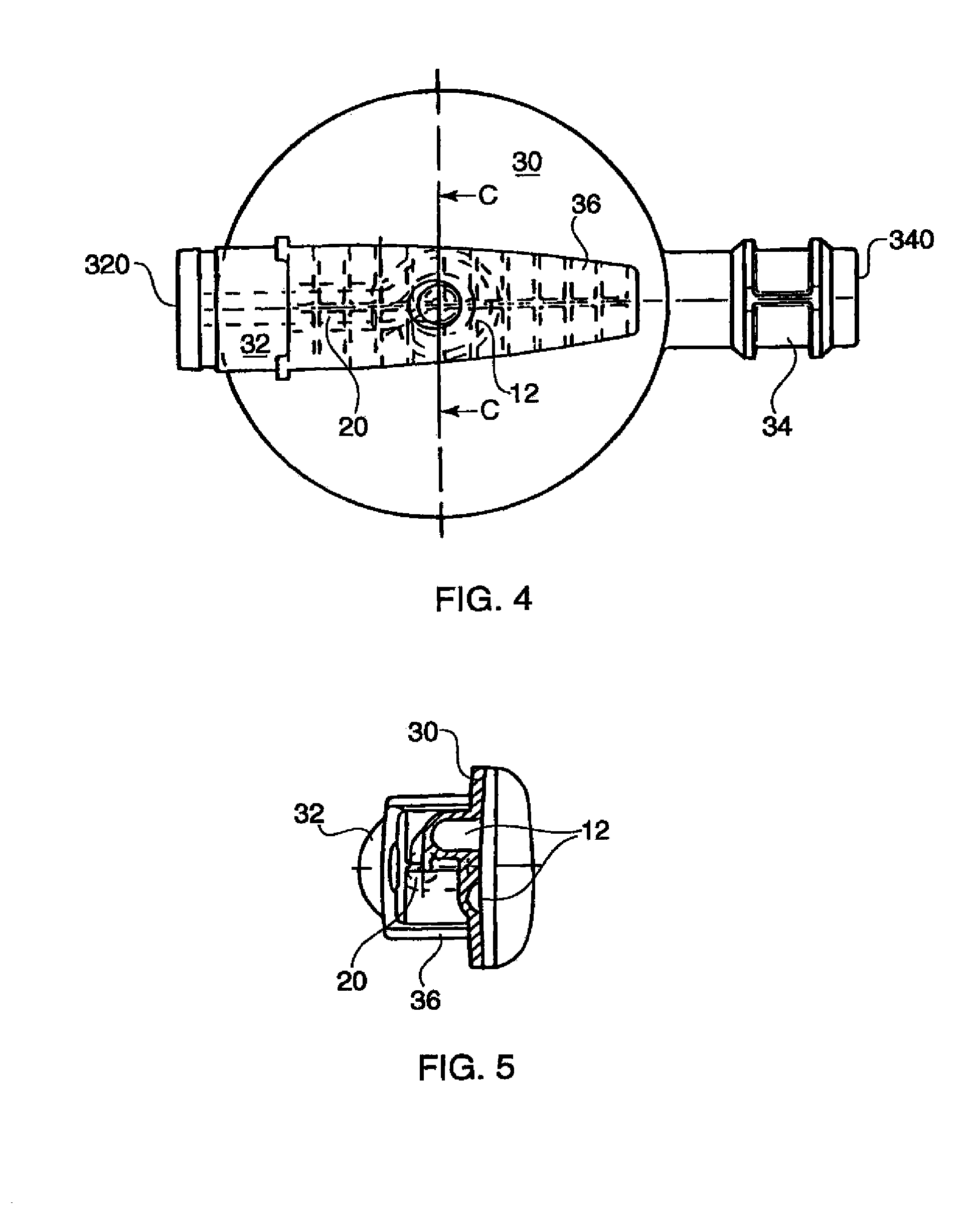

[0042]FIG. 1 shows a longitudinal sectional diagram of the end cap 30, which is in fluid-tight connection with the casing 40. End cap 30 has inflow or outflow chamber 10 adjacent to the semicircular channel 12. Liquid leaving semicircular channel 12 is carried into the inflow or outflow chamber 10 and is distributed in an essentially radially symmetrical pattern over the ends of the hollow fibers of a hollow fiber bundle.

[0043]Channel 12 is connected to the inlet or outlet 20 which in its end area forms the mouth 320 of connection 32 of the filter device according to the present invention.

[0044]End cap 30 is provided with bead 36 which extends radially, with connection 32 being formed in its end area.

[0045]In the area of end cap 30 shown at the right in FIG. 1, connection 34 is provided, having mouth 340 which is connected to the second flow space formed by the interior 42 of the casing surrounding the fibers.

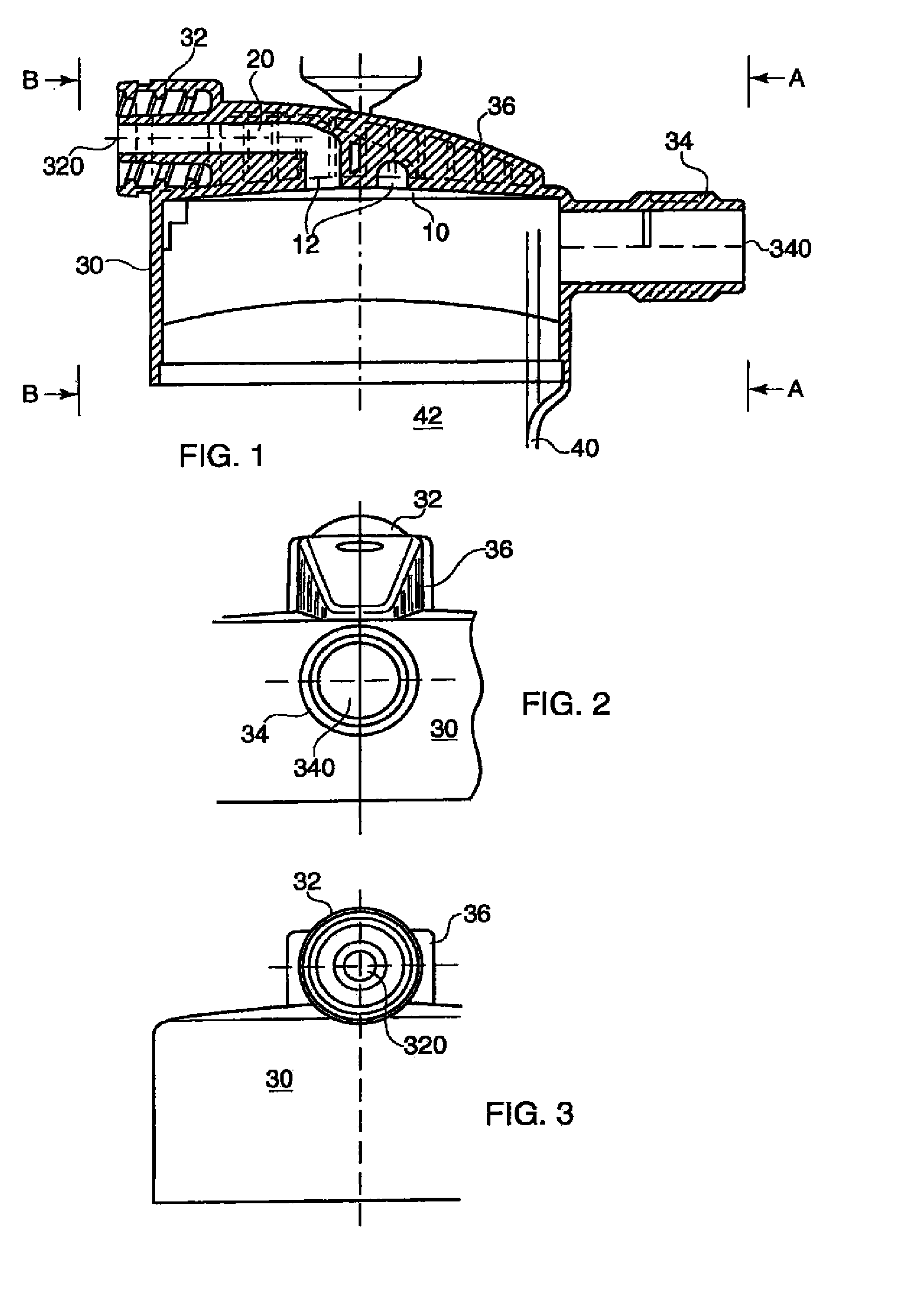

[0046]FIGS. 2 and 3 show the side views of the end cap 30 according to FIG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com