Resilient Sealing Sleeve

a sealing sleeve and elasticity technology, applied in the direction of engine sealing, yielding couplings, engine components, etc., can solve the problems of insufficient gas-tightness insufficient wear resistance and wear resistance of materials, and inability to meet the wear resistance and sealing requirements of today, so as to achieve great wear resistance and seal effect, effective sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

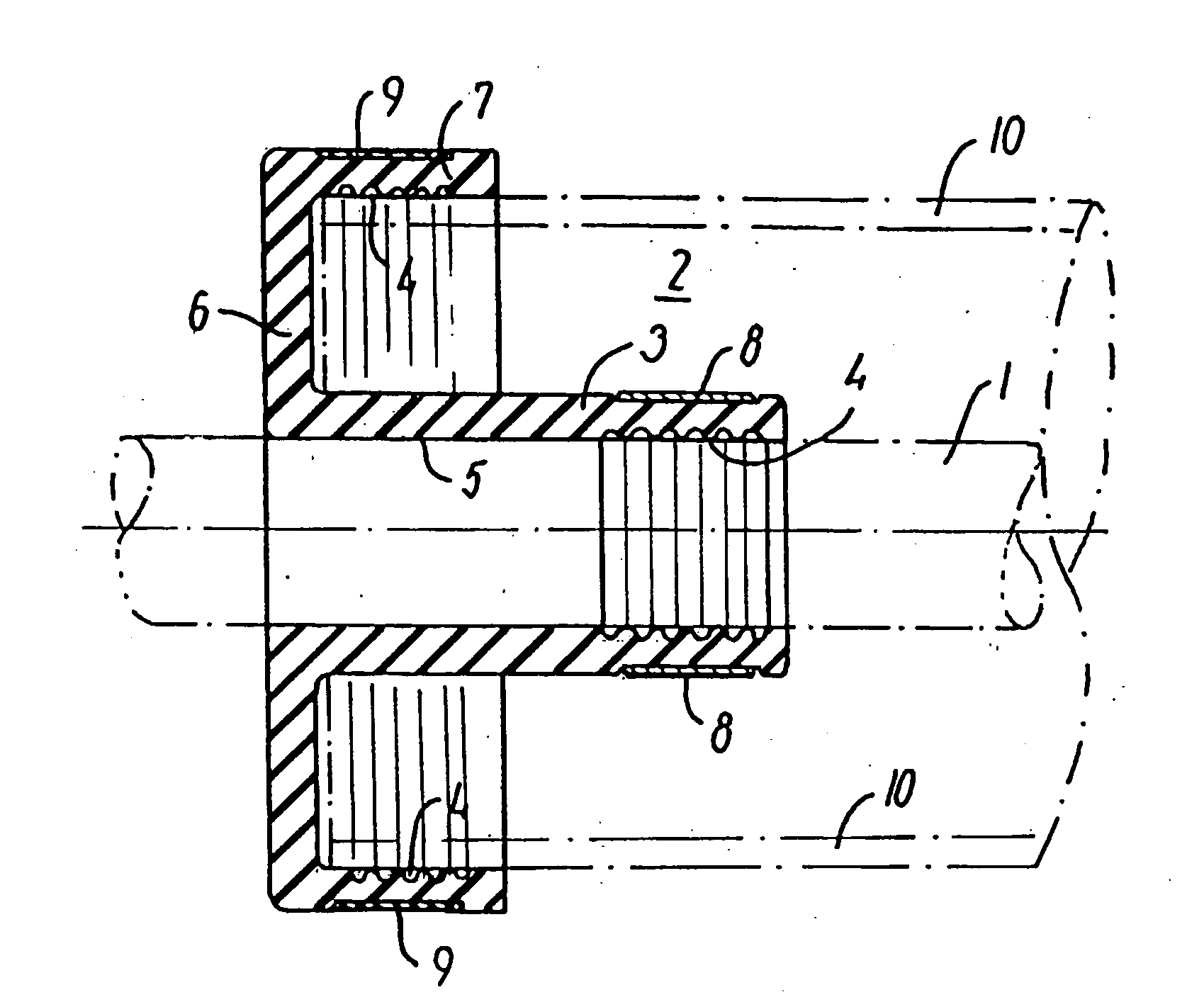

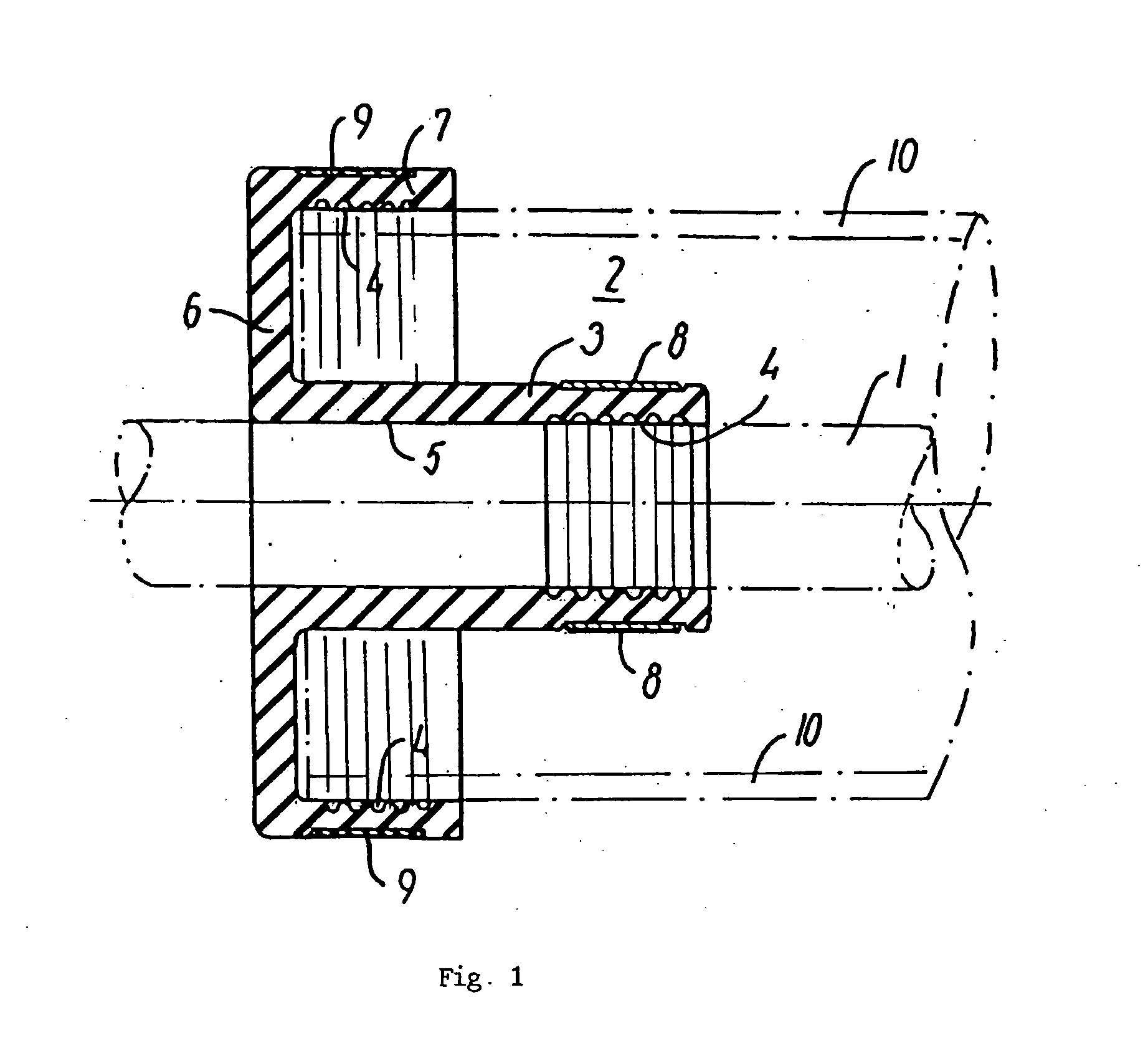

[0016]The embodiment shown in the drawing comprises a structure comprising a shaft 1 which extends inside a housing 10, 2 with lubricants, and where a sealing sleeve according to the invention surrounds the shaft 1 and the end face of the housing 10.

[0017]Interiorly, the sleeve comprises a bushing 3 which engages the shaft 1, and which is of such a length that a strap 8 or the like can easily be mounted.

[0018]The engagement face may be provided with ribs or waves 4, which gives an effective seal against “creeping” lubricant, if any, from the interior 2 of the housing and out.

[0019]At the end, the sleeve merges into an end wall 6 which is flat in the example shown, but which may be bellows-shaped or pleated, as needed, to accommodate angular deflections.

[0020]Finally, a ring portion 7 is provided externally on the sleeve, said ring portion engaging the housing or shield 10 which surrounds the shaft 1.

[0021]The extent of this ring portion 7 is such as to allow clamping by means of a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com