Outsole With Tangential Deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

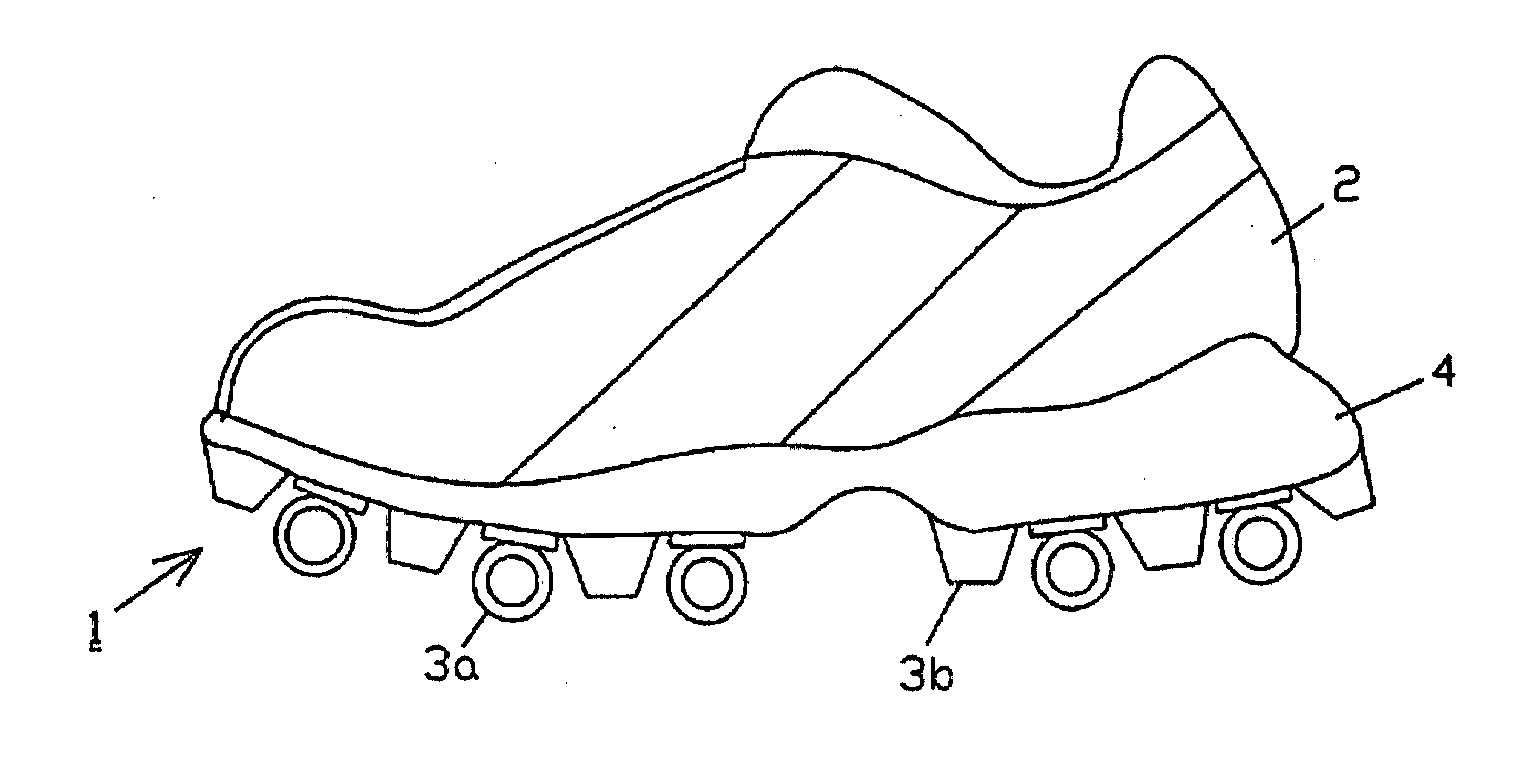

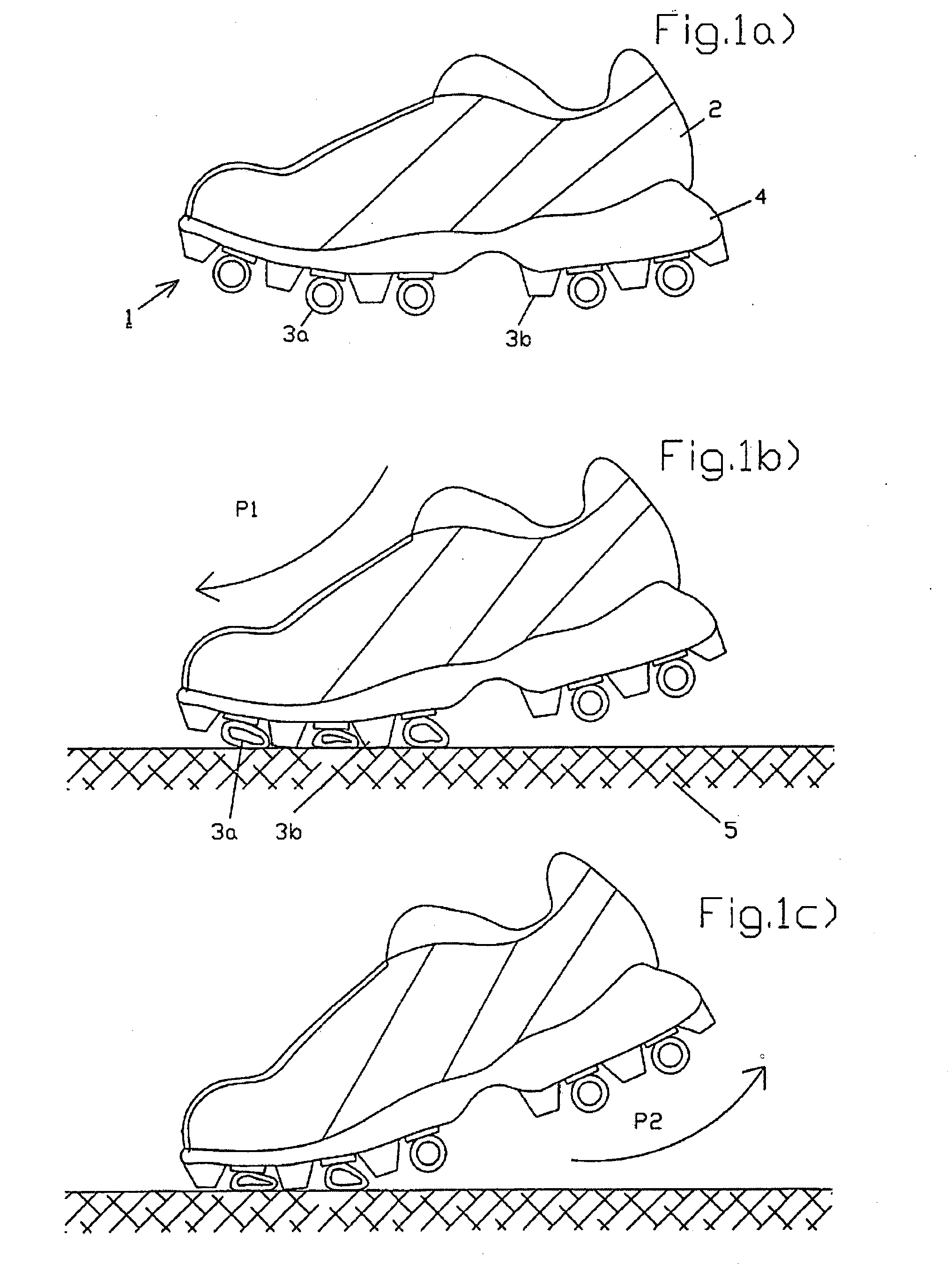

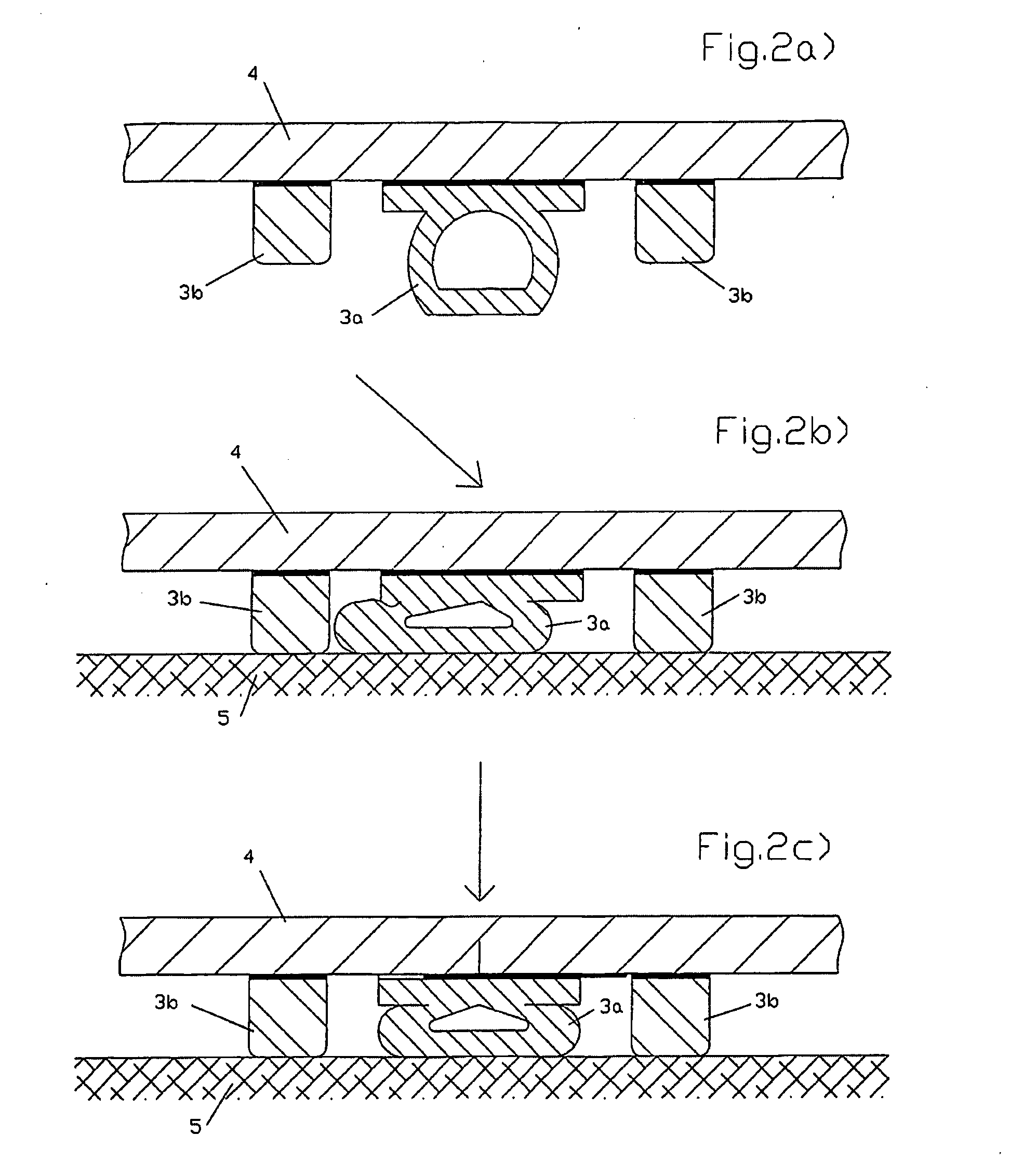

[0035]To begin with, an embodiment is described by means of FIG. 1, which is not necessarily the preferred embodiment, but by means of which, however, the inventive teachings can be represented well.

[0036]FIG. 1 shows a running shoe 2, which is equipped with an inventive outsole 1. The outsole 1 is formed by a plurality of first profile-like hollow elements 3a, similar to those already known from WO 03 / 102430, as well as by several platform-like second elements 3b. The hollow elements 3a may have a height of, for example, 15 mm and the platform-like elements 3b a height of, for example, 10 mm. The hollow elements 3a, as well as the second elements 3b may extend over the whole width of the running shoe 2. They may also, however, be disposed in several rows next to one another. The platform-like elements 3 may also enclose individual or several hollow elements 3a at least partly in annular fashion. The elements 3a, 3b are attached to the underside of an intermediate sole 4 of the runn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com