Apparatus and method for packaging siding panels

a technology for siding panels and apparatuses, applied in the direction of chutes, loading/unloading, packaging, etc., can solve the problems of reducing the throughput of extruders, repetitive stress injury, and complicating the packing of hanging strips, so as to facilitate the automatic packing process and reduce the level of operator participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

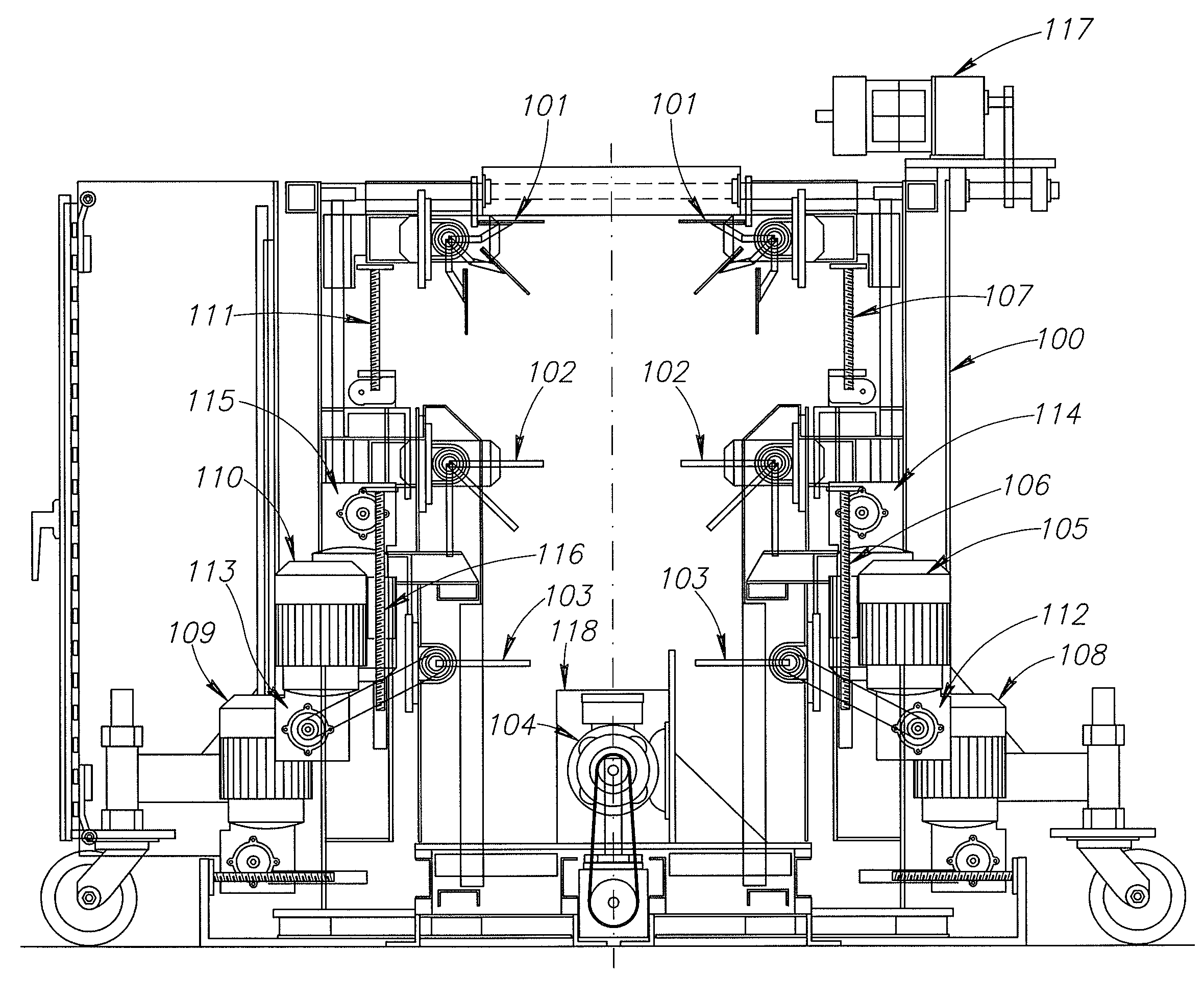

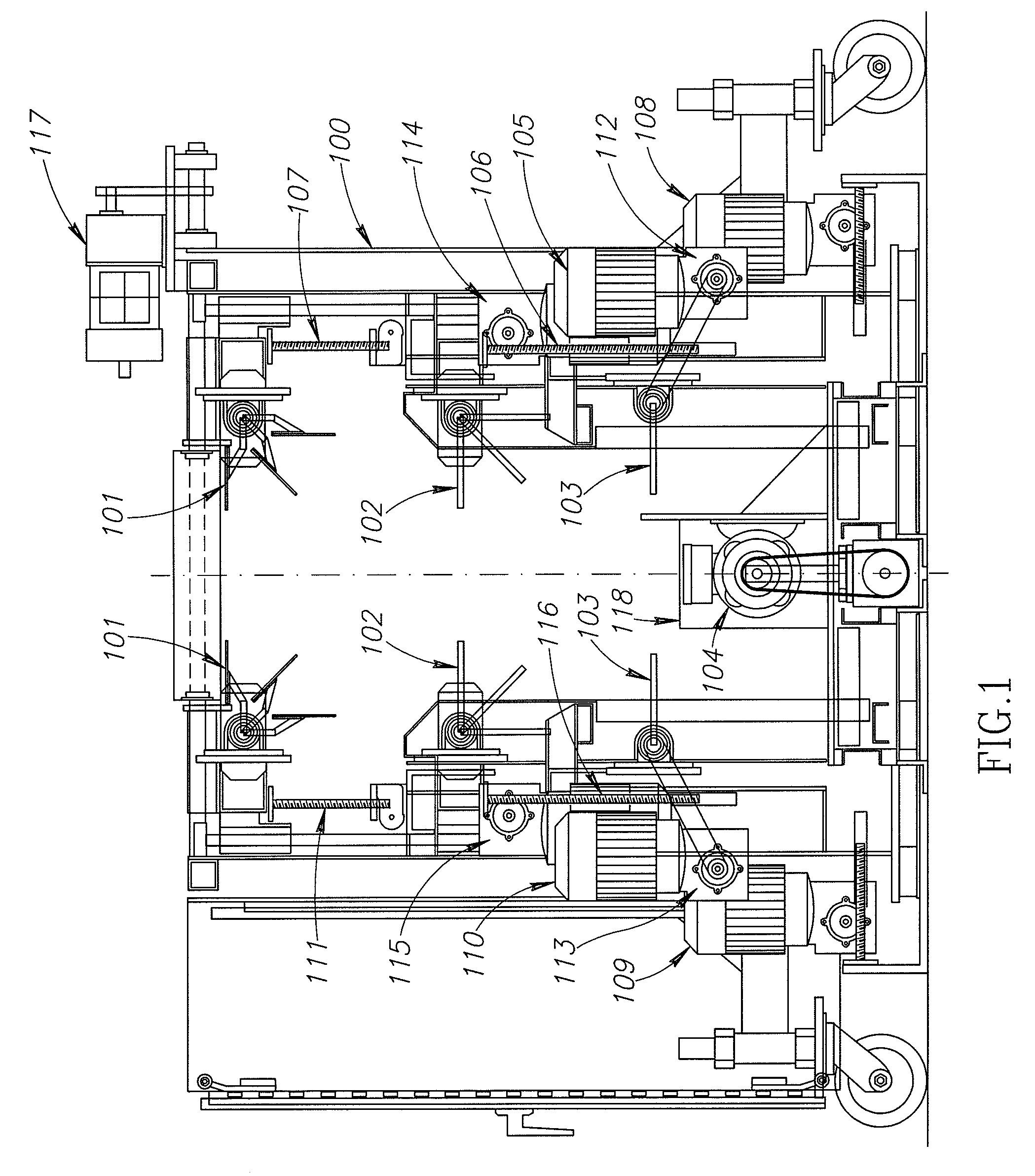

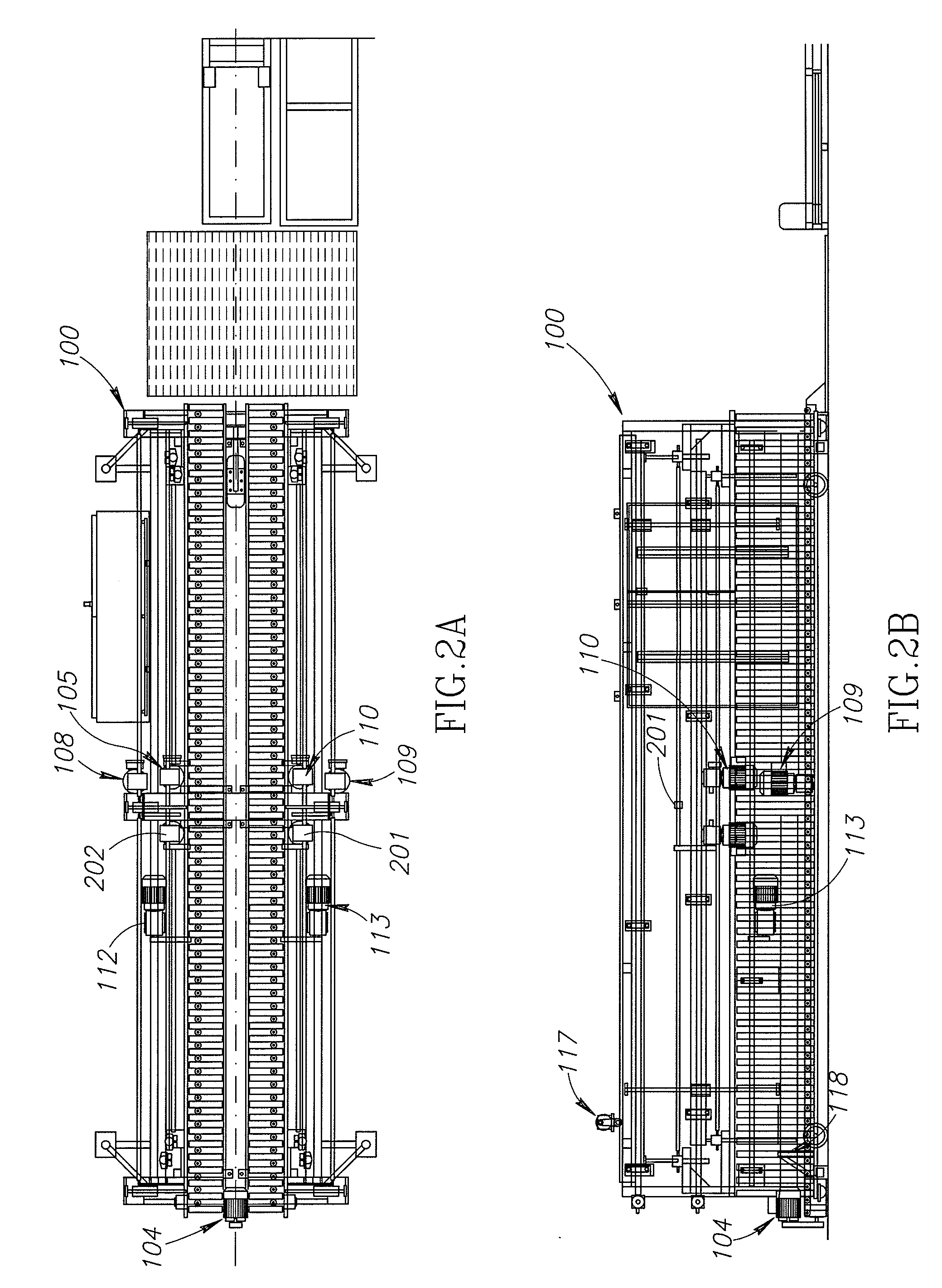

[0014]The present invention is designed to automatically package extruded vinyl siding or similar material such as vinyl soffit panels, in containers after manufacture. The apparatus of the present invention generally comprises a receiving section, a panel accumulation section and a transfer mechanism to transfer accumulated product into cartons. An end view of an apparatus in accordance with the present invention is shown in FIG. 1. As depicted therein, in a preferred embodiment, a packer 100 comprises receiving arms 101 adapted to receive manufactured siding, soffit material or the like after the extrusion process is complete. Disposed beneath receiving arms 101 are inverting pins 102 which operate to orient and nest extruded siding or soffit elements after being received by receiving arms 101. Receiving arms 101 and inverting pins 102 are designed to swing through pre-determined arcs in concert with one another to perform an orientation and nesting operation within packer 100. Ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com