Partitioned chimney cap and fireplace venting system

a chimney cap and venting system technology, applied in the field of partitioned chimney caps, can solve the problems of significant heat loss from the room, inefficient heat source of the conventional fireplace, and inability to draw cold air, so as to improve operational efficiency, reduce noise level, and reduce noise level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

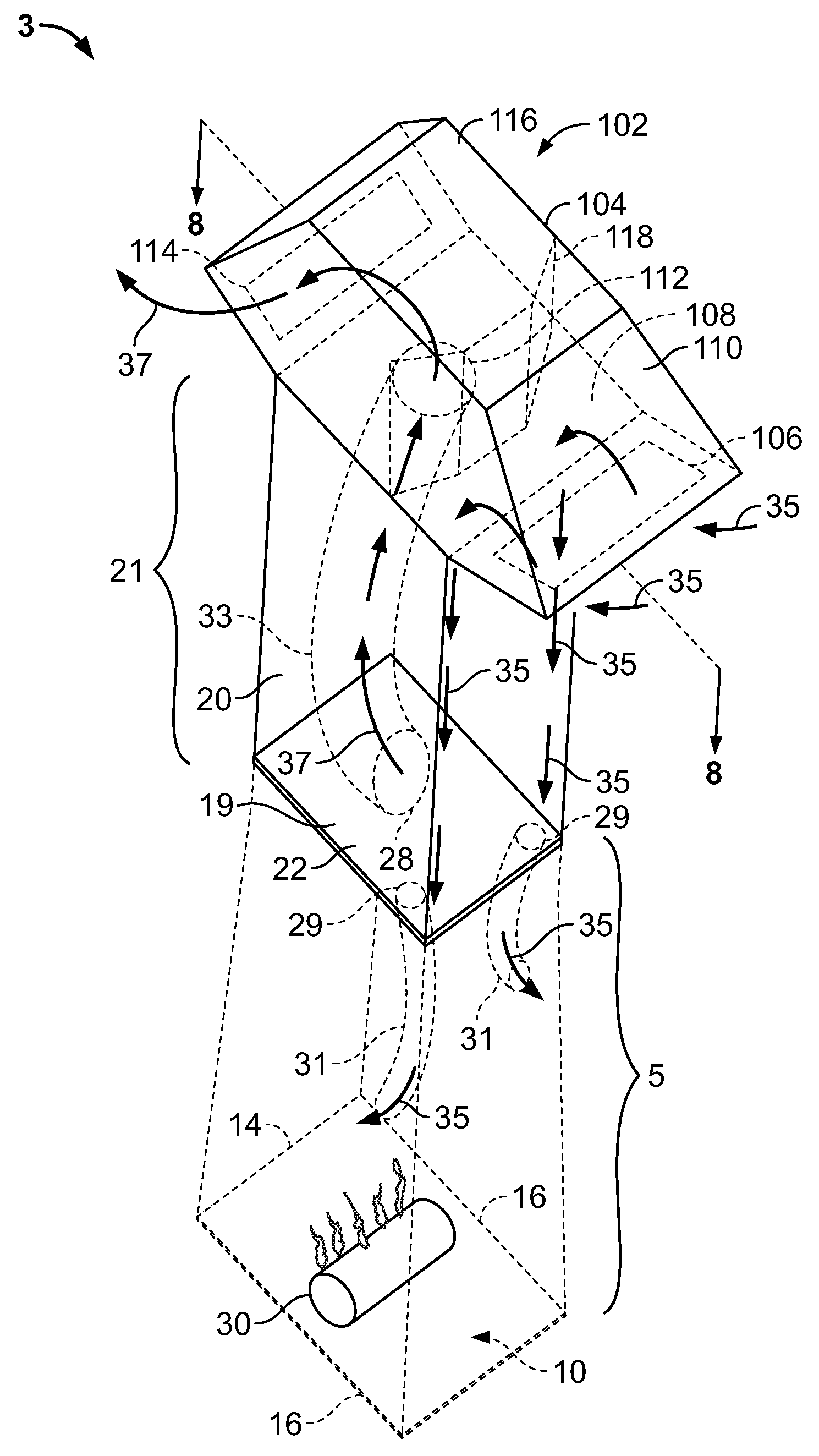

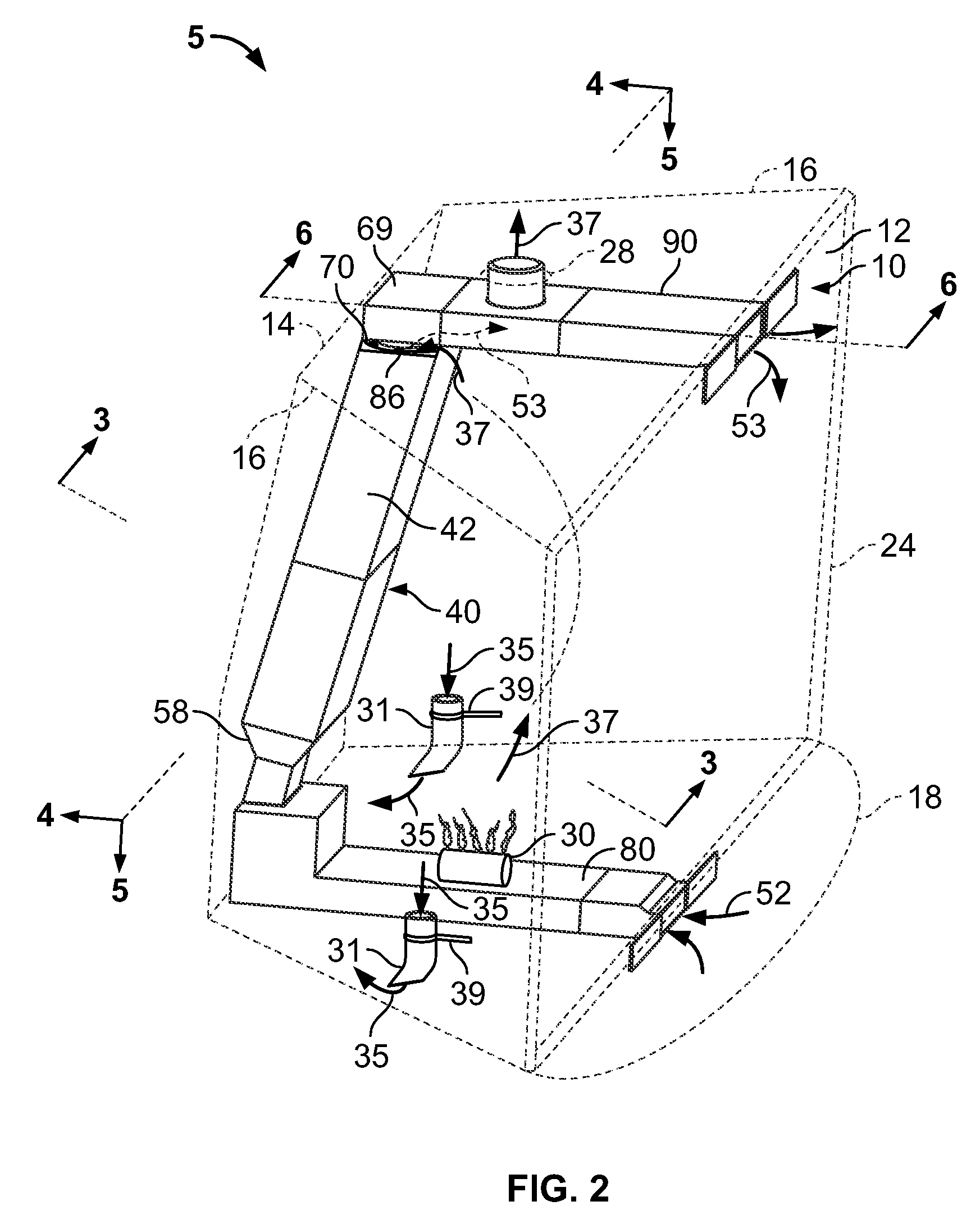

[0030]In FIGS. 1, 2 and 2A, there is shown a perspective view (and an exploded perspective view in FIG. 2A) of a fireplace 5 comprising a combustion chamber 10 having a front opening 12 (FIG. 2), a back wall 14, a pair of side walls 16, a hearth 18, and a chimney 21 including a chimney flue 20 connected to the top portion of the combustion chamber 10 by a throat or chimney opening 19. Combustion gases 37 produced in combustion chamber 10 are discharged through the chimney flue 20 by way of the throat or chimney opening 19, and then through a chimney cap 102. In one embodiment, fireplace venting system 3 conveys relatively cold outside air or combustion air 35 through chimney cap 102 and then through chimney flue 20 to combustion chamber 10, as will be discussed in further detail below.

[0031]FIGS. 1 and 2 further shows a suitable type of gas log burner 30 for producing heat energy that is supplied with heating gas from an external source. These gas log burners 30 are well known in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com