Sheet Conveying Device

a conveying device and sheet technology, applied in the direction of thin material processing, printing, article separation, etc., can solve the problems of not being removed, not attached to a portion of the belt, printing failure, etc., to prevent the effect of reducing the print quality due to the change of belt speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

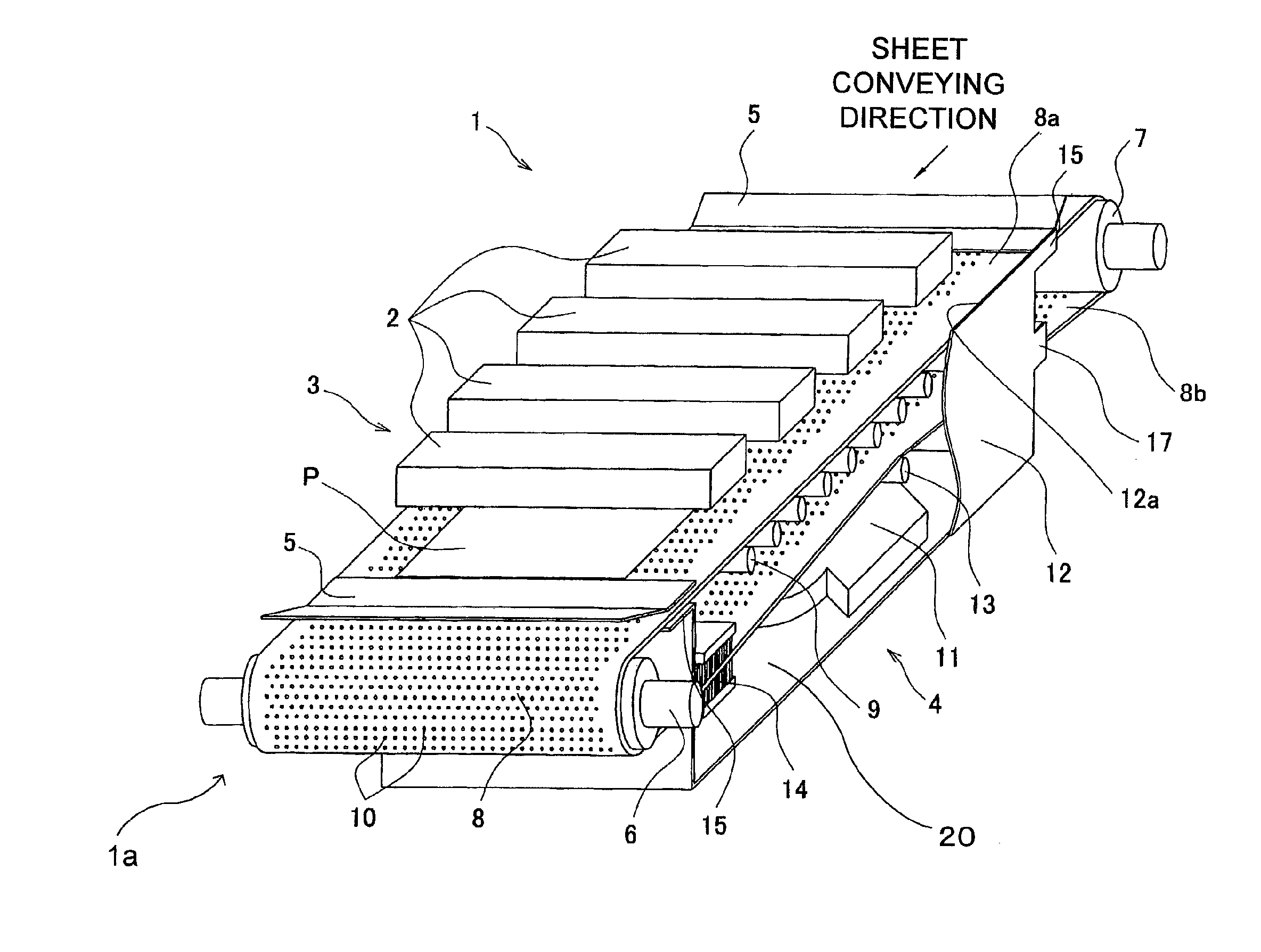

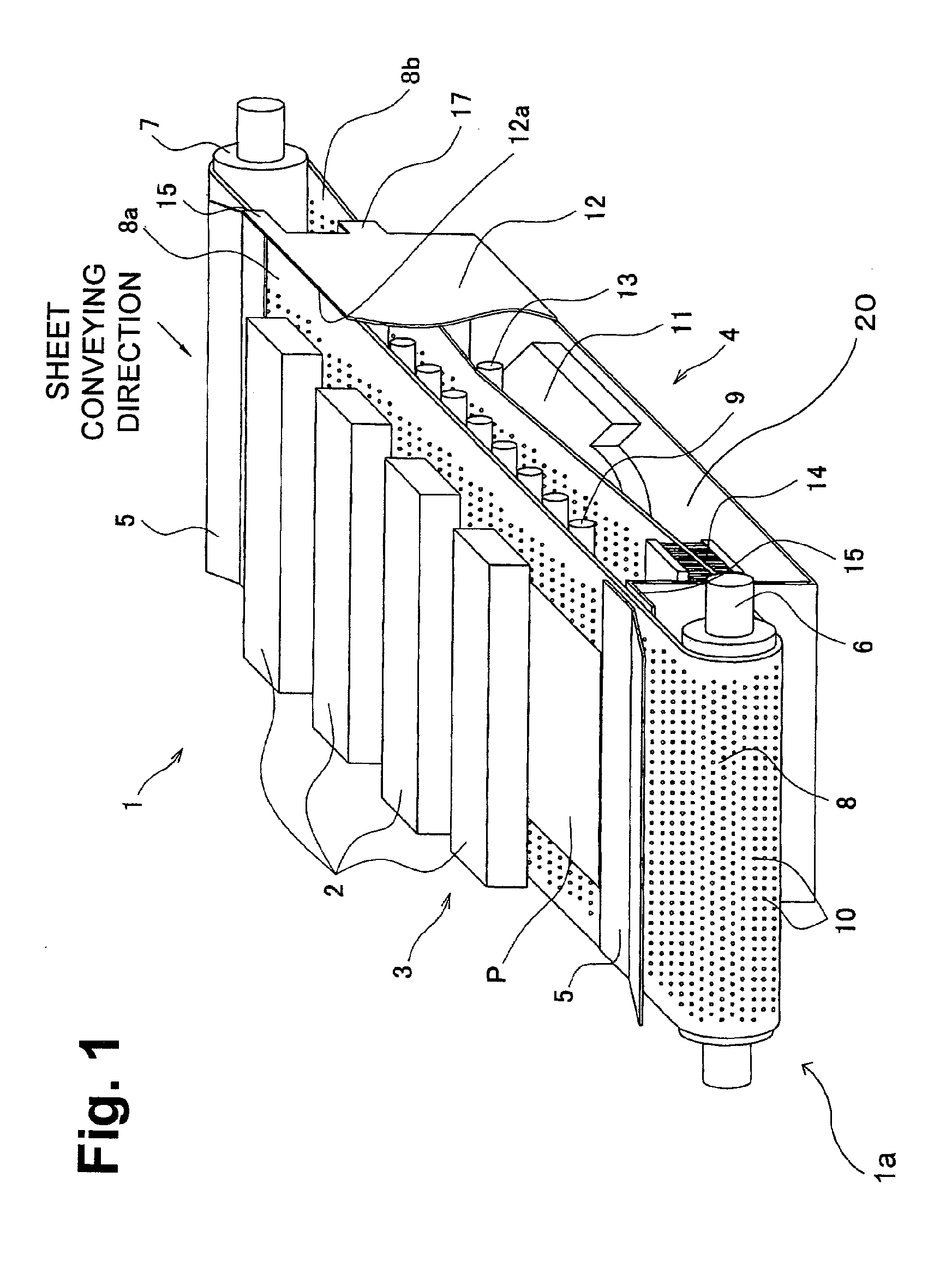

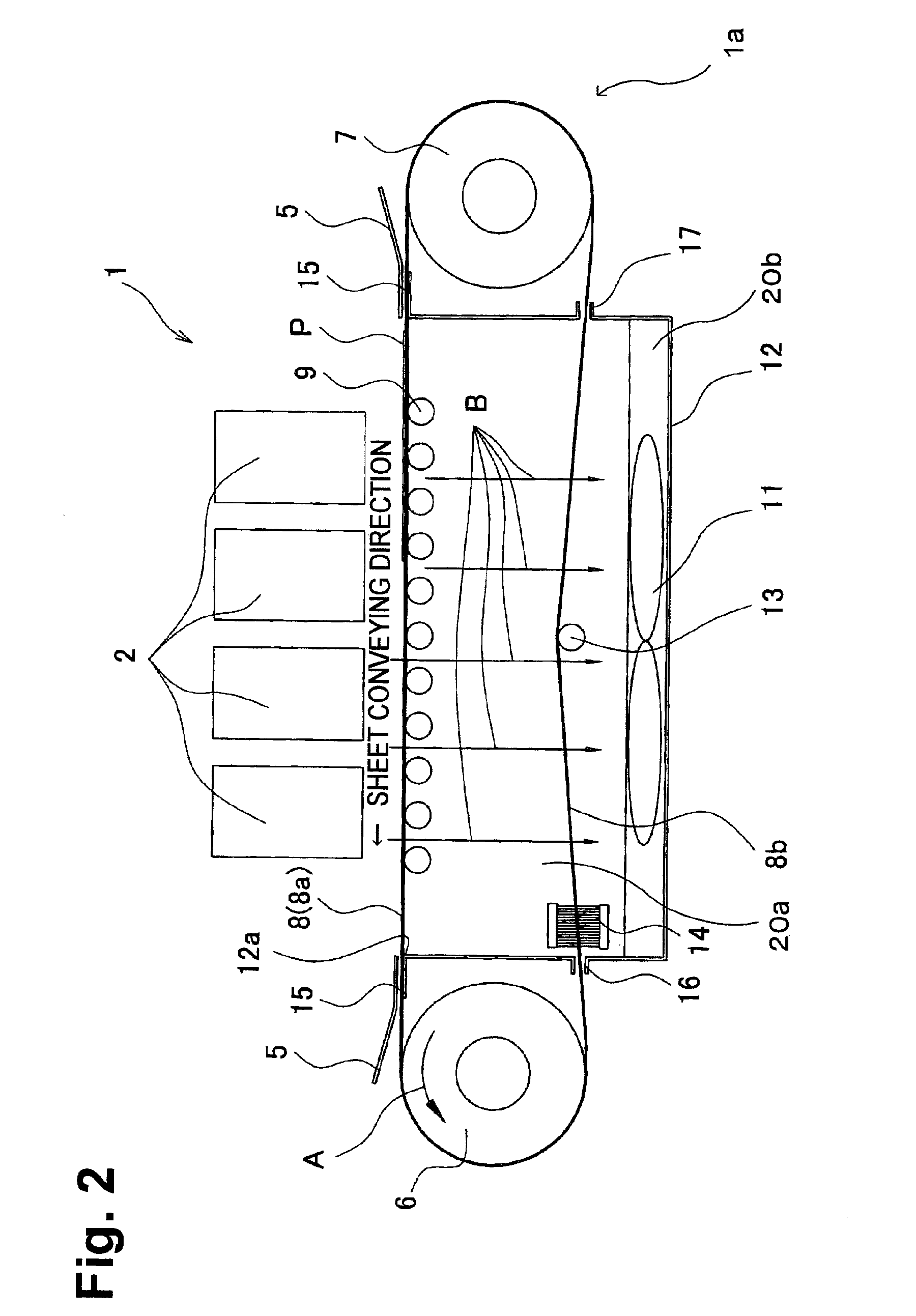

[0022] Embodiments are described in detail with reference to the accompanying drawings. One or more embodiments may be applied to inkjet printers that form characters and / or images by ejecting ink onto recording sheets.

[0023] As shown in FIGS. 1 and 2, a color inkjet printer 1 comprises four print heads 2, and a sheet conveying device 1a including a conveyor unit 3 and a suction unit 4.

[0024] Inkjet printer 1 may be a line printer comprising four print heads 2, each of which corresponds to one of four ink colors (e.g., magenta, yellow, cyan and black) arranged in a sheet conveying direction. Each of the four print heads 2 may be of a hexahedral shape elongated in a direction perpendicular to the sheet conveying direction. Bottom surfaces of print heads 2 face a conveying belt 8. Ink droplets of each color are ejected to a print area defined on an upper print surface of a sheet P when sheet P, conveyed by the conveying belt 8 sequentially, passes under print heads 2. Thus, a color ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com