Multiple barrel frozen product dispenser

a product dispenser and multi-barrel technology, applied in the field of frozen product dispensers, can solve the problems of affecting the efficiency of conventional refrigeration systems, affecting the balance of refrigeration systems, and reducing the temperature of saturated evaporators, and achieve the effect of efficiently handling large variations in cooling load demands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

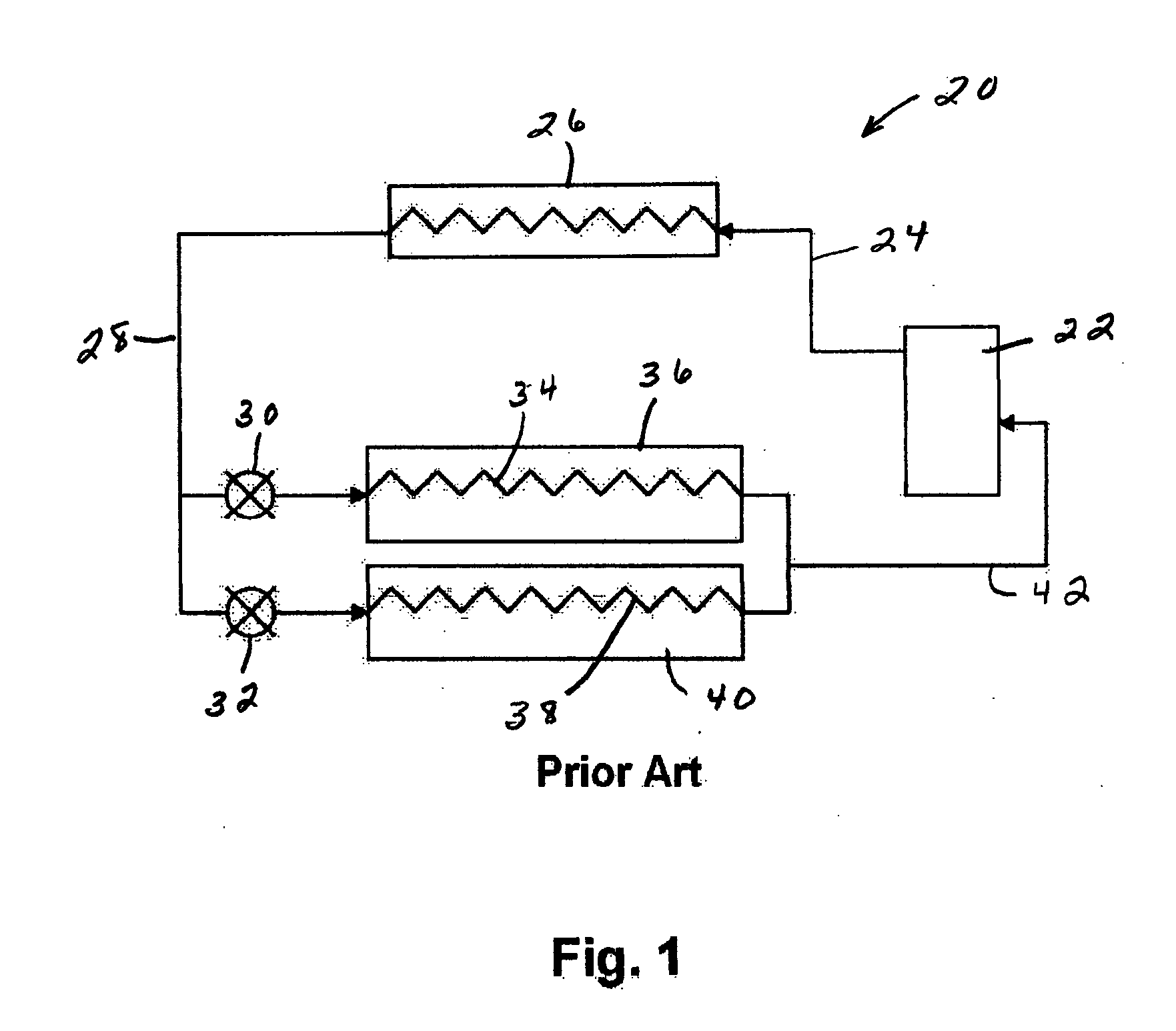

The Prior Art

[0016]FIG. 1 shows a known type of refrigeration system, indicated generally at 20, for use in chilling product freeze barrels of a frozen product dispenser. The refrigeration system has a fixed speed compressor 22 that delivers hot refrigerant from its outlet through a line 24 to an inlet to a condenser 26 for cooling of the refrigerant. Upon leaving the condenser, the cooled refrigerant flows through a line 28 to inlets to each of a pair of variably controlled expansion valves 30 and 32. The expansion valve 30 adjustably meters refrigerant to an evaporator 34 heat transfer coupled to a product freeze barrel 36 to chill the barrel and freeze product in it. The expansion valve 32 adjustably meters refrigerant to an evaporator 38 heat transfer coupled to a product freeze barrel 40 to chill barrel and freeze product in it. Refrigerant exiting the evaporators 34 and 38 flows through a suction line 42 to an inlet to the compressor 22. Liquid product components, which may b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com