Method for Melting Magnesium and Melting Apparatus

a technology of magnesium melt and melting apparatus, which is applied in the direction of heat treatment apparatus, furnaces, manufacturing tools, etc., can solve the problems of economic damage, reduced magnesium melt amount, and damage to the furnace, so as to increase the flow rate of the cover gas, reduce the cost, and increase the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental example

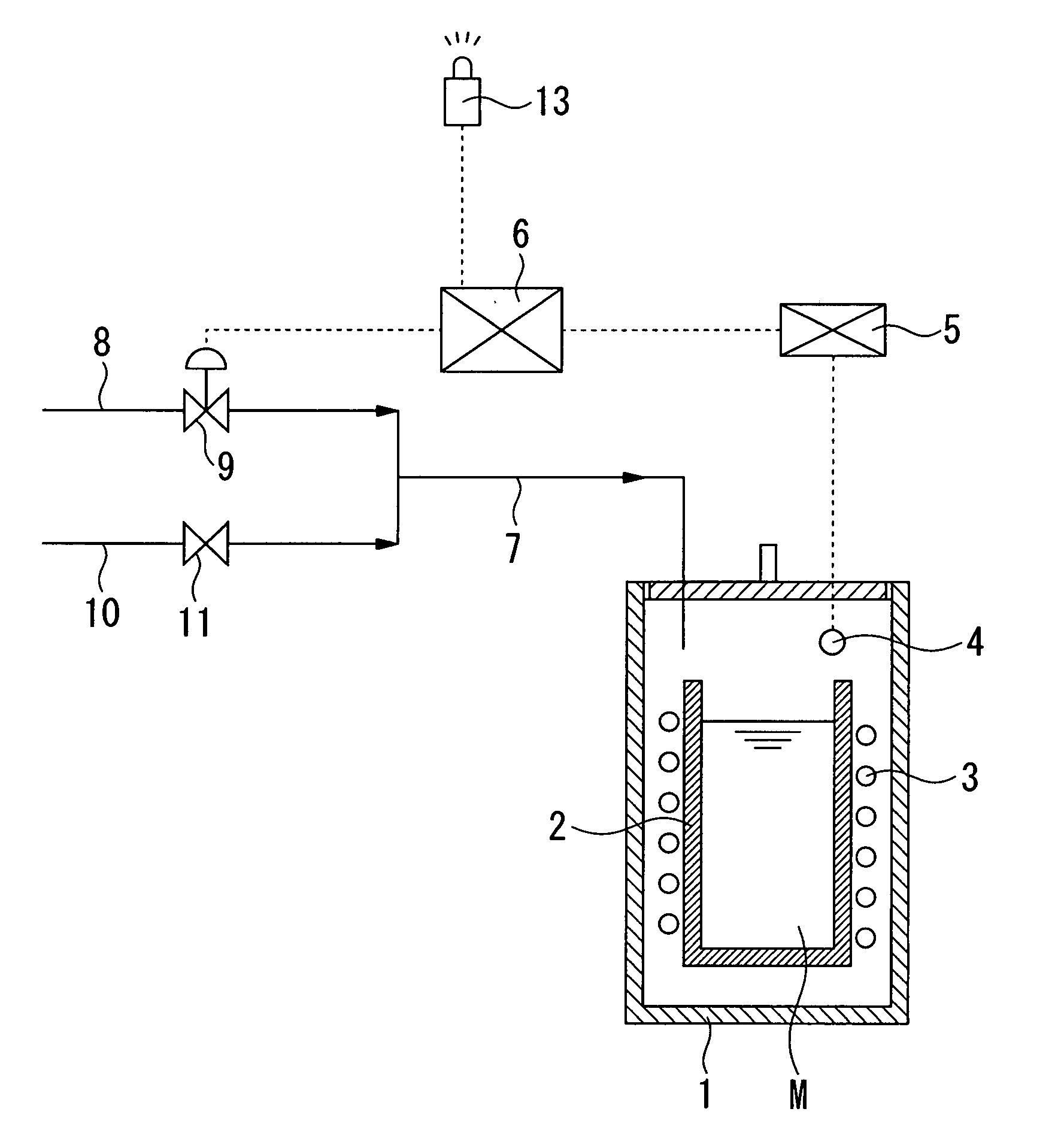

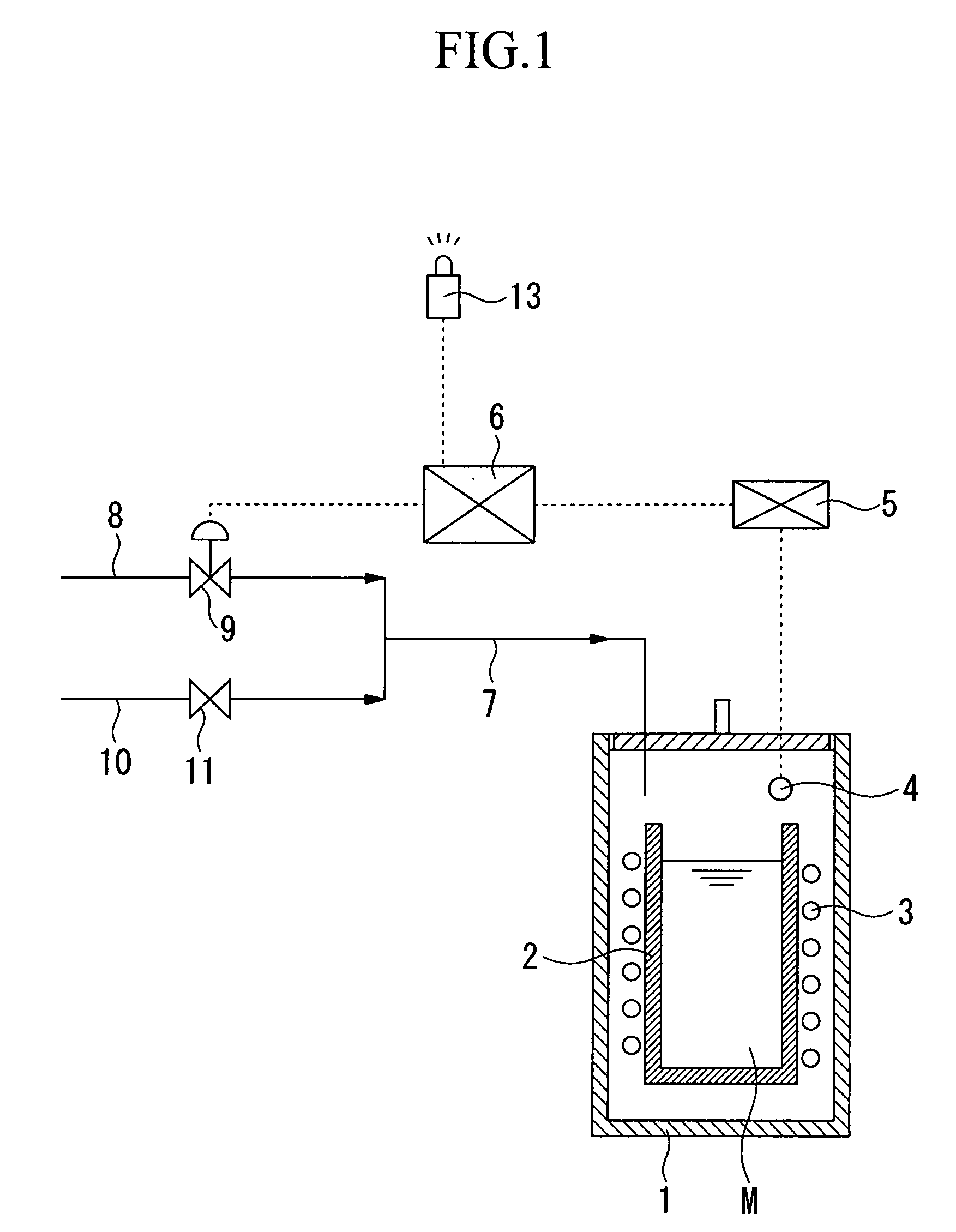

[0056] In this Example, the melting apparatus shown in FIG. 1 was used. The inner diameter of the furnace 1 was 300 mm, and the height was 670 mm. The inside of the furnace 1 could be watched through the heat-resistant glass in the furnace cover.

[0057] The crucible 2 having an inner diameter of 200 mm and a height of 300 mm was positioned in the furnace 1. A magnesium melt, which was obtained by melting 4.7 kg of magnesium alloy (AD91D), was put in the crucible 2. The temperature of the magnesium melt was maintained at 680° C.

[0058] A diluted gas, which was obtained by diluting 1,1,1,2,2,4,4,5,5,5,-nonafluoro-4-(trifluoromethyl)-3-pentanone which is a fireproof agent with carbon dioxide such that the concentration be 200 ppm, was used as a cover gas. The cover gas was supplied to the furnace 1 from the pipe 7 at a rate of 7.5 litter / min. The concentration of carbon monoxide in the furnace 1 was measured by the sensor 4 and the carbon monoxide concentration meter 5.

[0059] The vari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com