Low cost high yield Iso-octene/ Isooctane process with capability to revamp the MTBE units

a technology of isobutylene and octane, which is applied in the direction of hydrocarbon preparation catalysts, hydrocarbon oil treatment products, sustainable manufacturing/processing, etc., to achieve the effects of enhancing catalyst life, reducing isobutylene concentration, and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

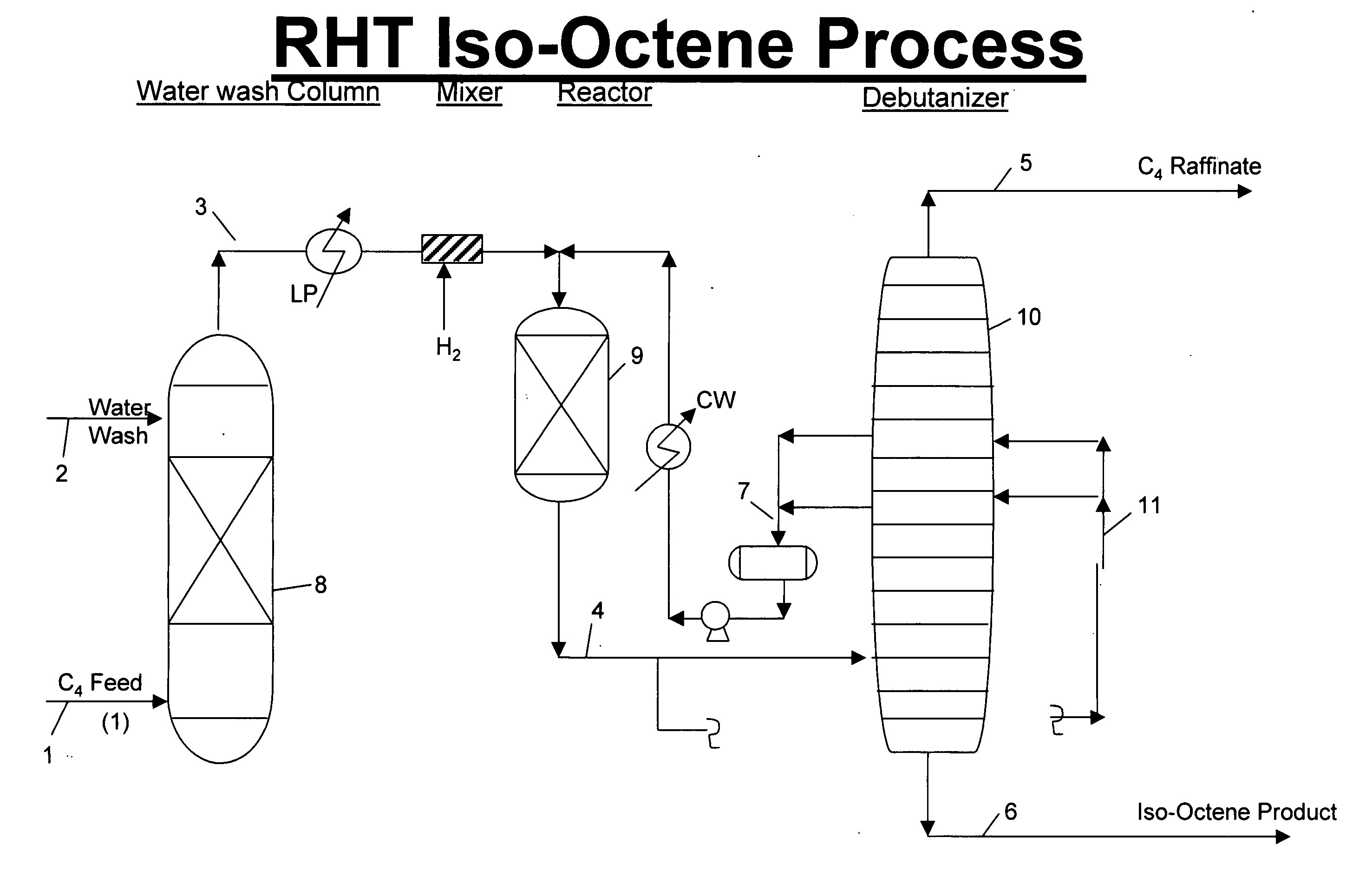

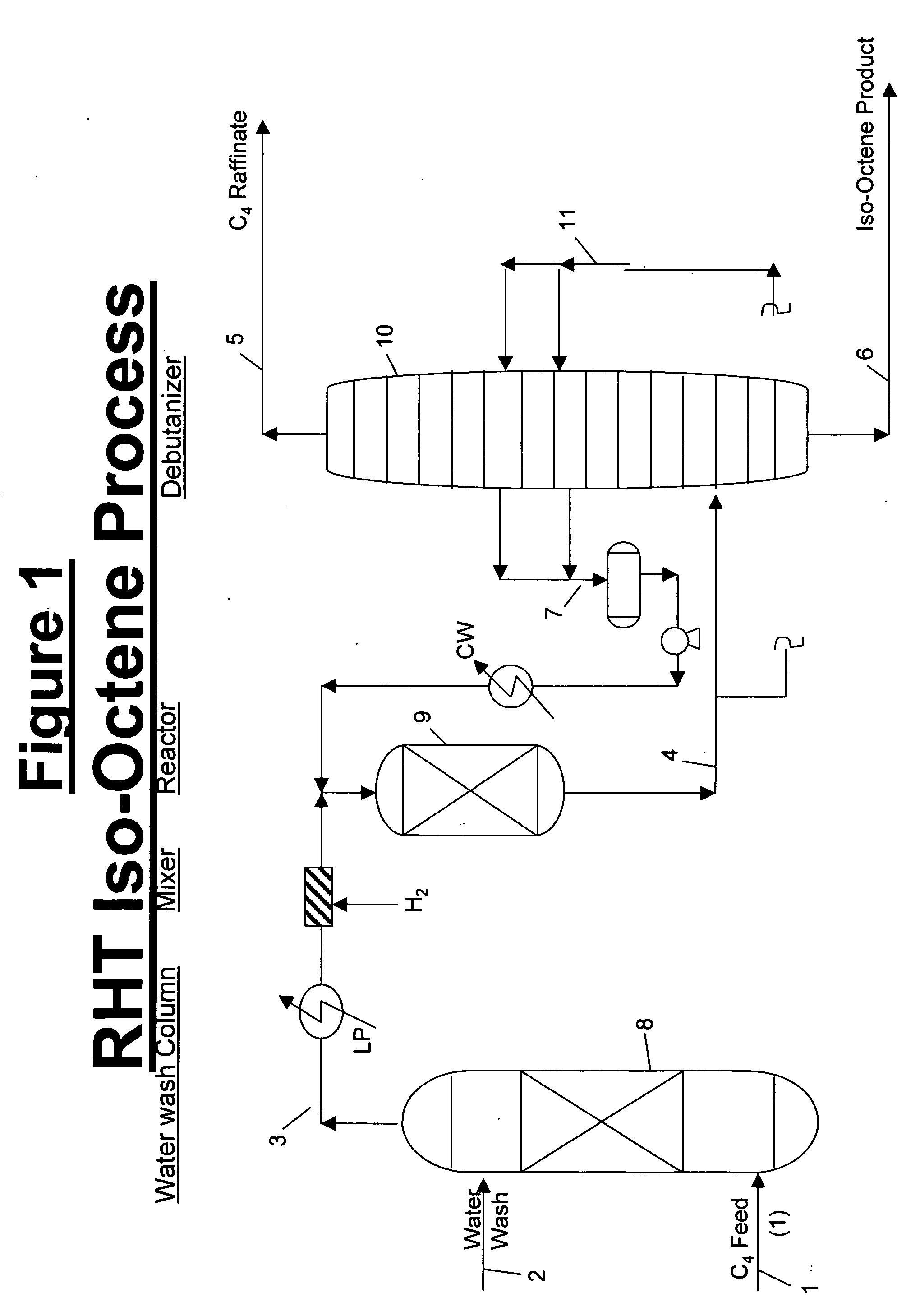

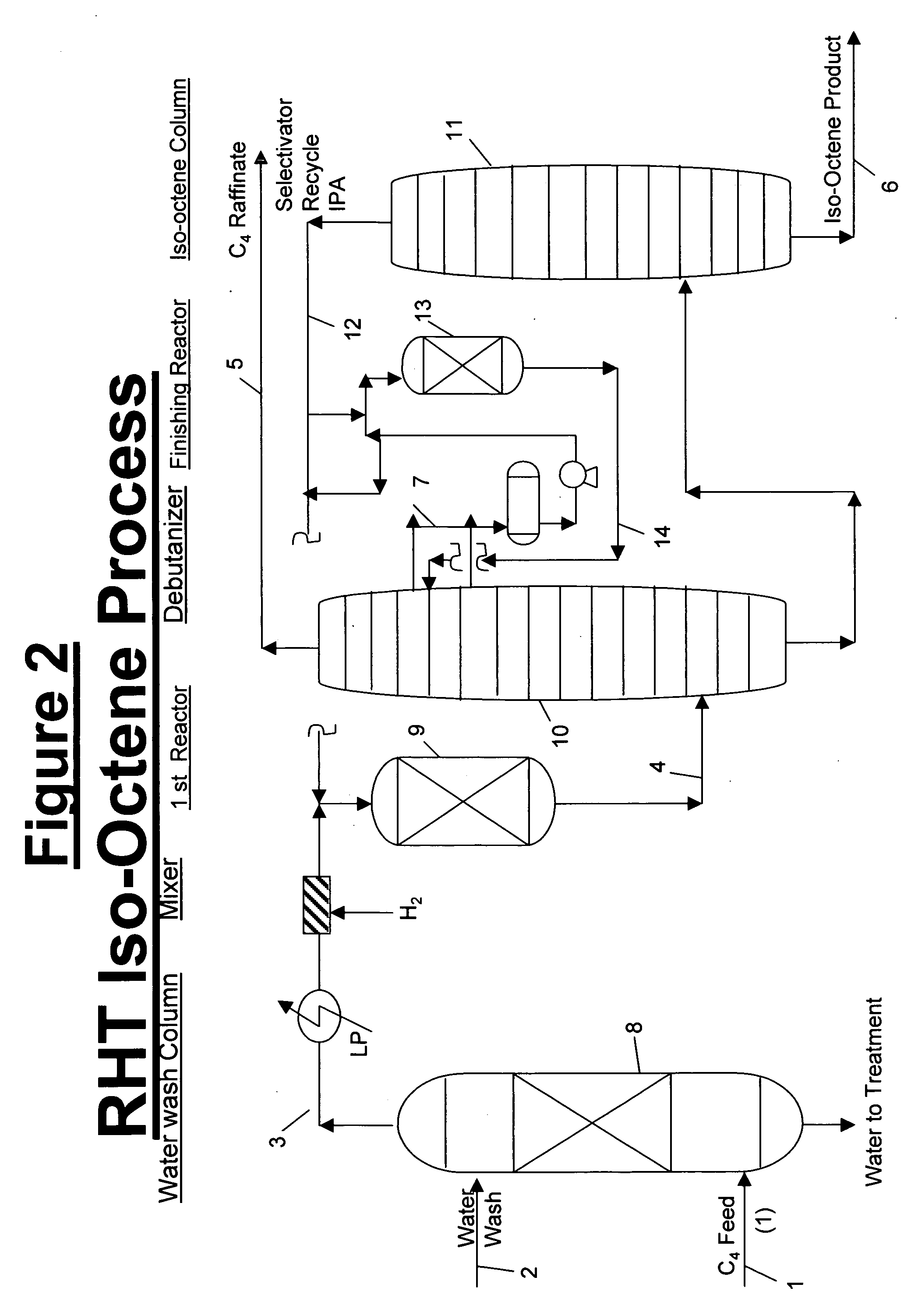

Method used

Image

Examples

examples

[0039]The following example illustrates the feeds which could be used for making Iso-octene. These could be from multiple sources FCC C4 Stream, Steam Cracker C4 Stream and on purpose Isobutane Dehydrogenation units, which can provide good feed for Iso-octene production. The higher concentration feeds need is well suited to this configuration.

C4 Feed from the FCC unit:Componentwt %Propane1.2Propylene0.7Isobutane23.9Isobutylene17.81-Butene13.7c-2-butene12.6t-2-butene14.3n-butane15.3C5's0.5Total100.00Iso-octene ProductC8 olefins90 to 92%C12 Olefins7.5 to 9.0%Other byproducts0.5 to 2.0%Iso-octane ProductC8 Paraffins91 to 93%C12 Paraffins 7 to 8.5%Other impurities0.5 to 2.0%

[0040]The following reaction conditions and yields can be expected from this unit:

Based on the configuration and feed compositions following conditions will be required for the first and Side reactors configuration:[0041]Inlet Temp (F) 100 to 180 (100 to 130 F preferable)[0042]Pressure (psig) 100 to 175[0043]LHSV (h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| inlet pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com