Apparatus for wellbore communication

a technology for communicating equipment and wellbore, which is applied in the field of apparatus for oil and gas wellbore, can solve the problems of mud and damage to formations, conventional overbalanced drilling and underbalanced drilling, and drill string thrown out of well, so as to reduce manufacturing costs, control and seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

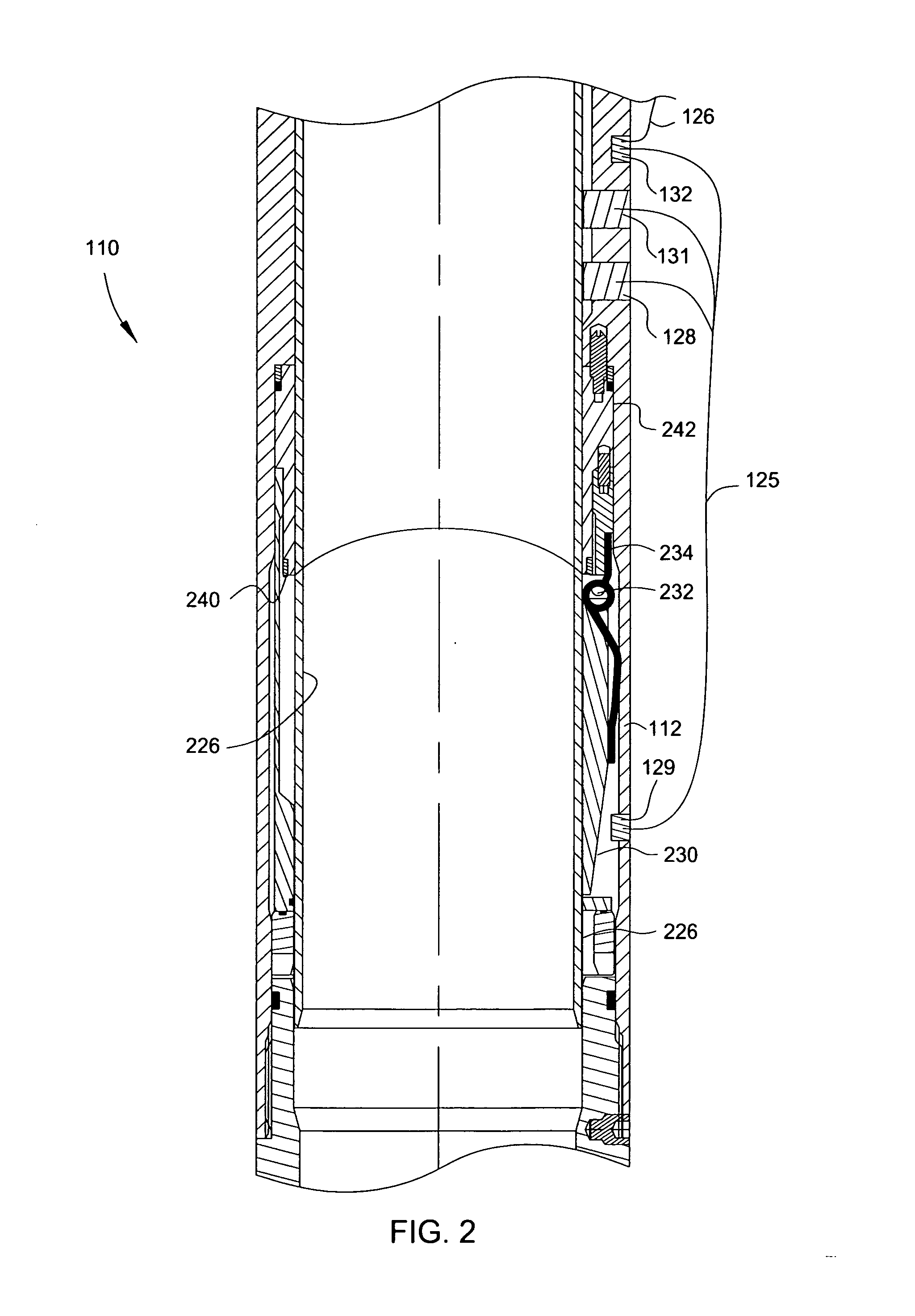

[0036] Embodiments of the present invention provides methods and apparatus for communicating between surface equipment and downhole equipment. One embodiment of the invention provides a wellhead assembly that allows electrical power and signals to pass into and out of the well during drilling operations, without removing the valve structure above the wellhead, resulting in time and cost savings. Another embodiment of the invention provides an electromagnetic communication system for two-way communication with downhole tools that addresses the limitations of EM telemetry such as the gradual decay of EM waves as the EM waves pass through the earth's lithosphere and when a salt dome or water-bearing zone is encountered. Yet another embodiment of the invention provides an antenna module for a resistivity sub that effectively controls and seals the primary / secondary interface gap which can be manufactured with a wider range of tolerances to reduce the manufacturing costs.

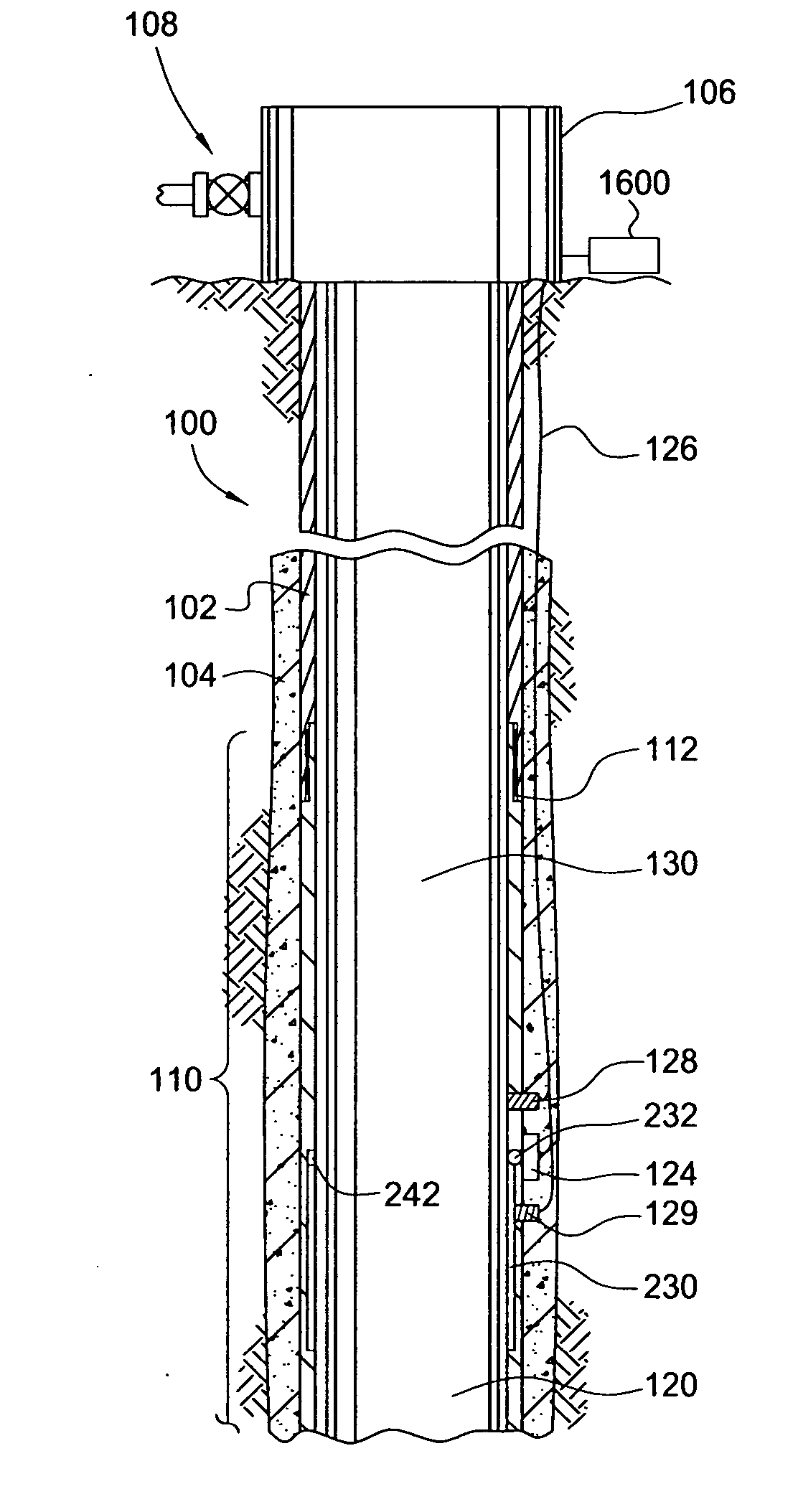

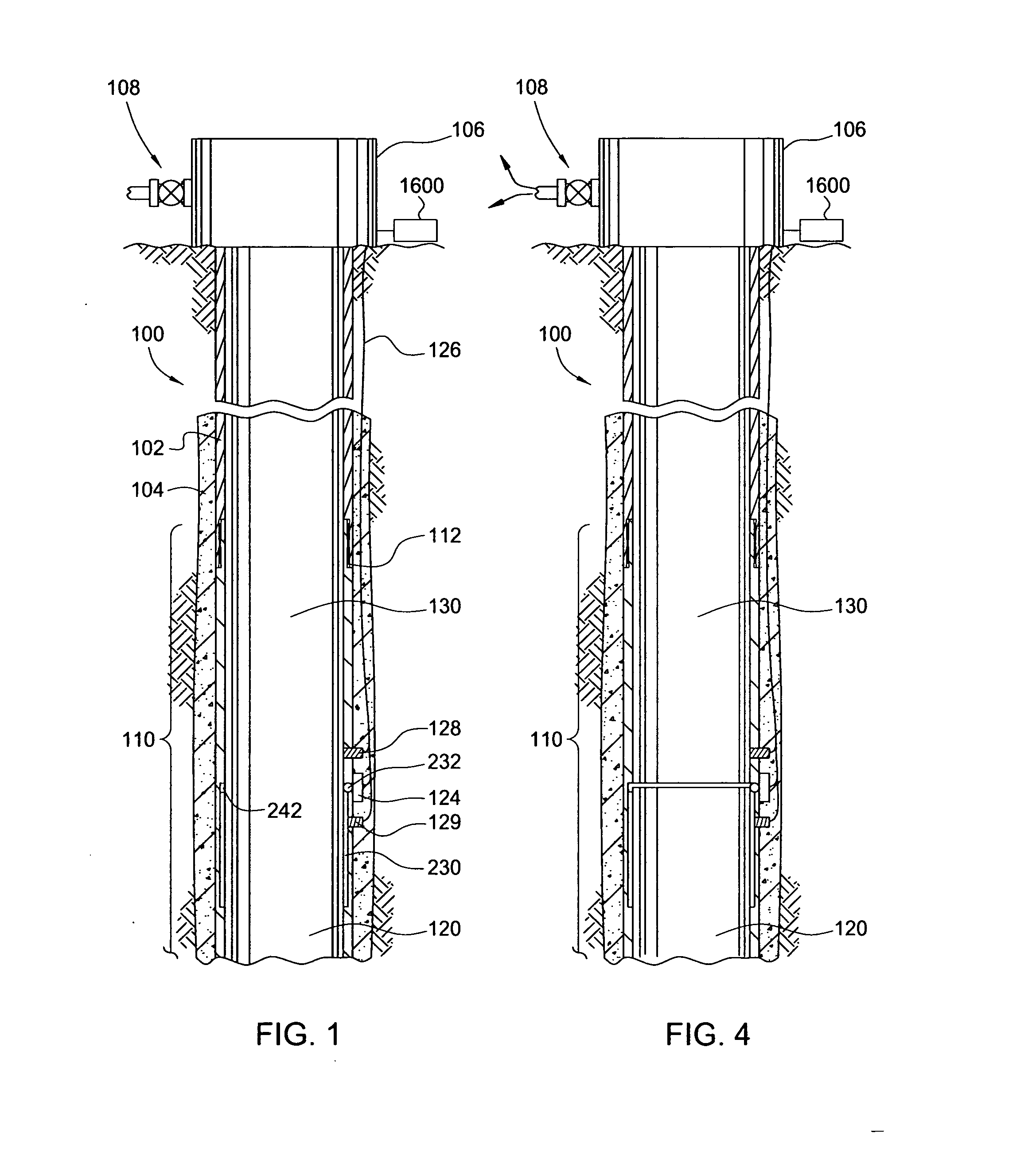

[0037]FIG. 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com