High-cleaning, low abrasion, high brightness silica materials for dentrifices

a technology of high brightness and silica materials, applied in the field of unique abrasive materials, can solve the problems of affecting the cleaning effect of dentin pellicle film, exhibiting a high abrasion level, and exhibiting a limited level of such properties, and achieve excellent dentin abrasion and pellicle film cleaning ability, excellent thickening properties, and desirable abrasives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

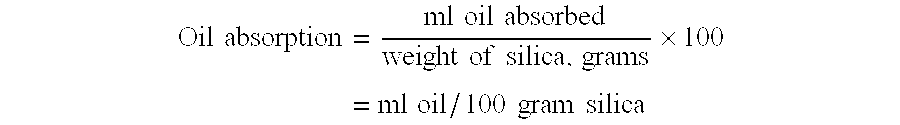

Method used

Image

Examples

example

[0064] The inventive example initially involved the provision of 8140 liters of 6.0% sodium silicate to which was added 11.4% sulfuric acid at a rate of 191.3 liters / minute for 8 minutes at a temperature of 50° C. within a reactor. The resultant silica gel-containing slurry was then heated up to 93° C. for 53 minutes thereafter. Subsequently, 13 minutes into the heating step, high shear flow of 3000 liters / minute of reactor slurry (gel) was started and continued throughout the remainder of the example production. After the 53 minutes completed, 30 kilograms of dry weight of sulfuric acid (243.8 liters) was then added to the gel slurry. Thereafter, simultaneous sulfuric acid and sodium silicate addition was started with introduction of both to the reactor to initiate the precipitation step. The sodium silicate of 16.21% concentration (at a temperature of 85° C.) was added at 339 liters / minute and dilute sulfuric acid (11.4% concentration) was introduced at 191.3 liters / minute. The si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com