Liquid crystal display

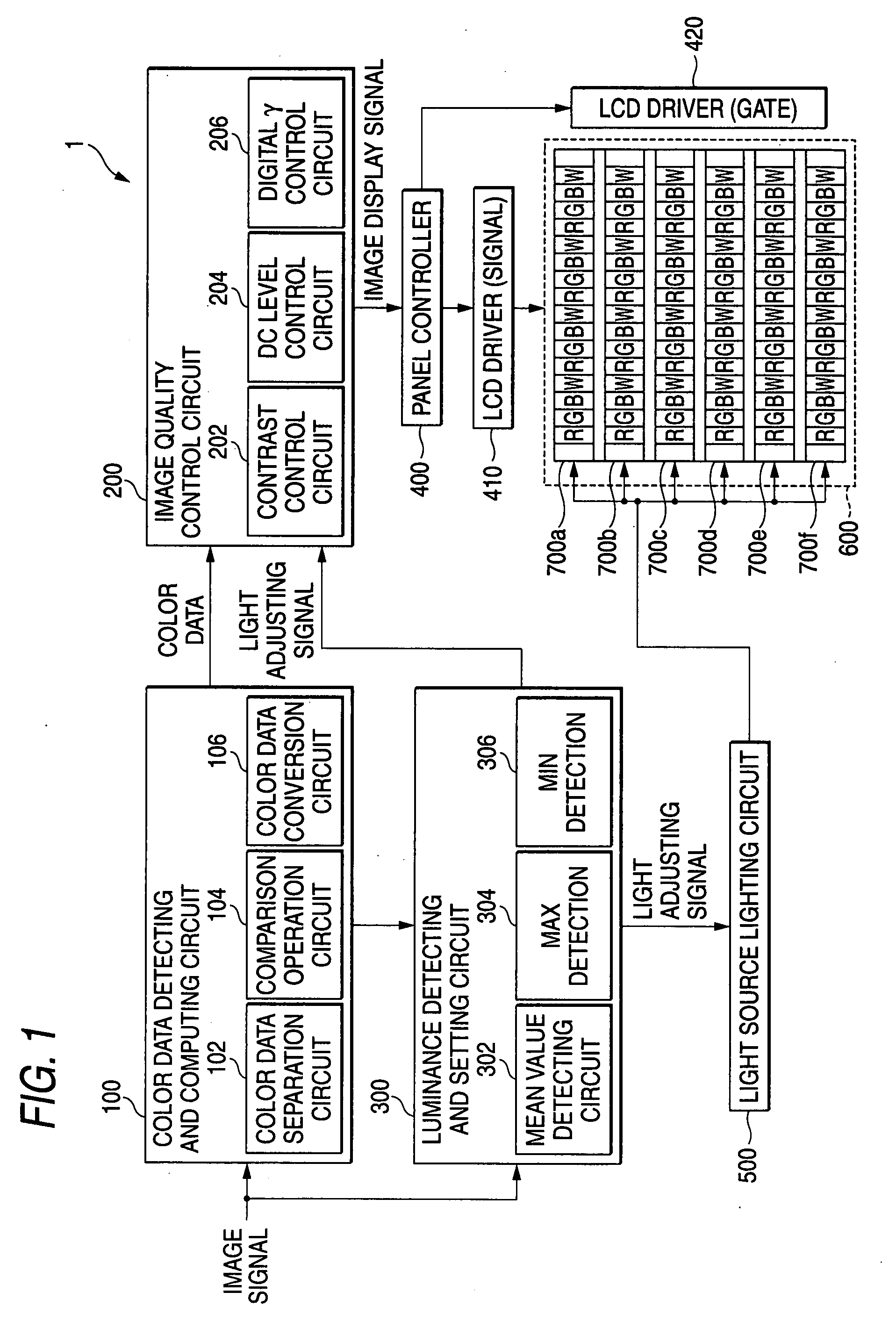

a liquid crystal display and display image technology, applied in the direction of instruments, static indicating devices, etc., can solve the problems of low efficiency of use as display lights, the difficulty of liquid crystal displays to implement complete moving picture displays, and the inability to achieve the improvement of the image quality of the display image of liquid crystal displays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0191]A more specific description will be given of the invention by citing examples.

(Fabrication of Liquid Crystal Display)

[0192]Two elliptically polarizing plates were adhered in such a manner as to sandwich the bent alignment cell. The transmission axis of one polarizing plate was disposed at 90° in the plane of the screen, while the transmission axis of the other polarizing plate was disposed at 0° in the plane of the screen.

[0193]The arrangement provided was such that the optically anisotropic layer of the elliptically polarizing plate opposed the cell substrate, and the rubbing direction of the liquid crystal cell and the rubbing direction of the optically anisotropic layer opposing the same were anti-parallel.

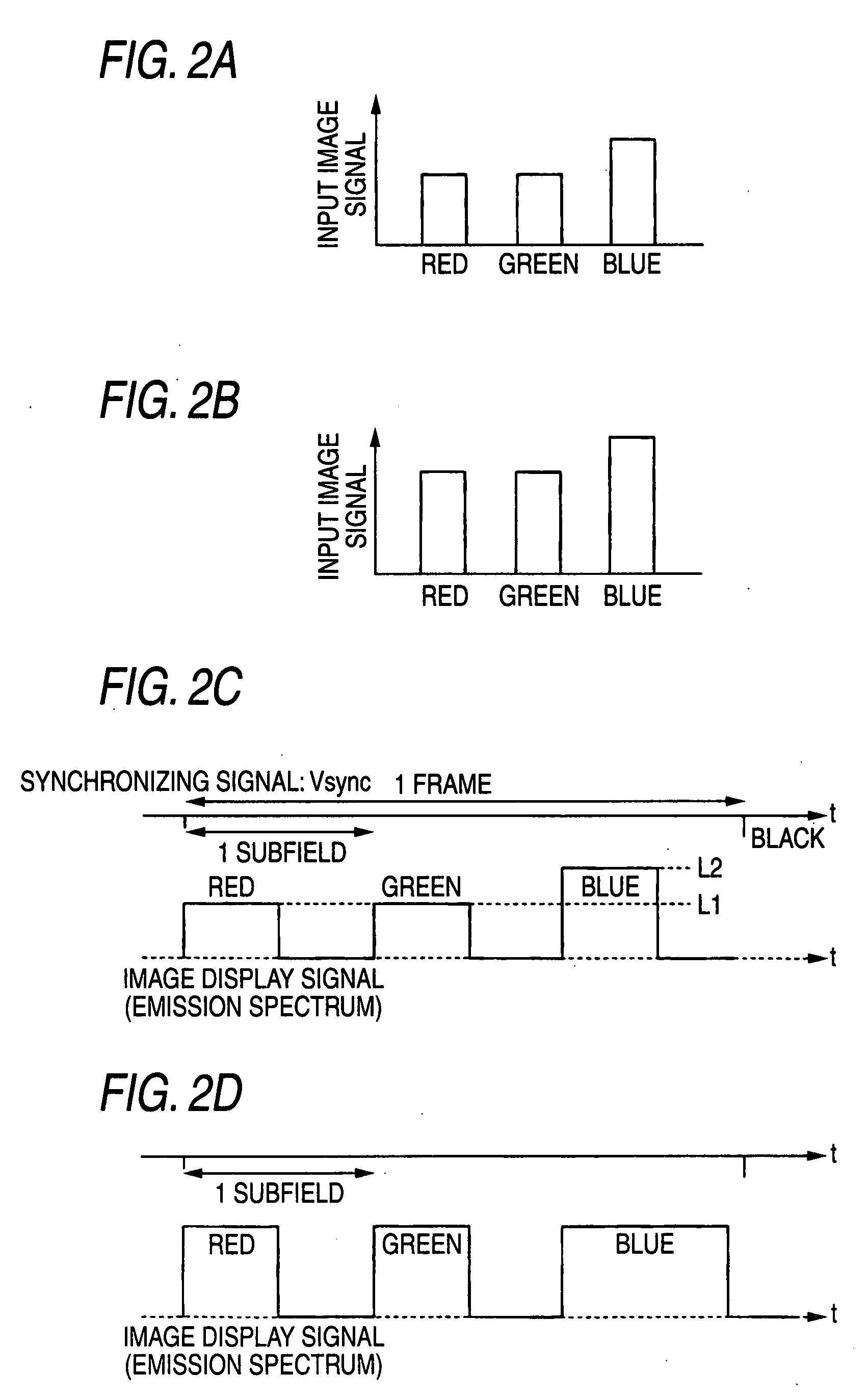

[0194]The liquid crystal display thus fabricated was disposed on a field sequential backlight constituted by four colors of LED light sources, a white display voltage of 2 V was applied to the liquid crystal cell, and color coordinates in the normal direction of the panel...

example 2

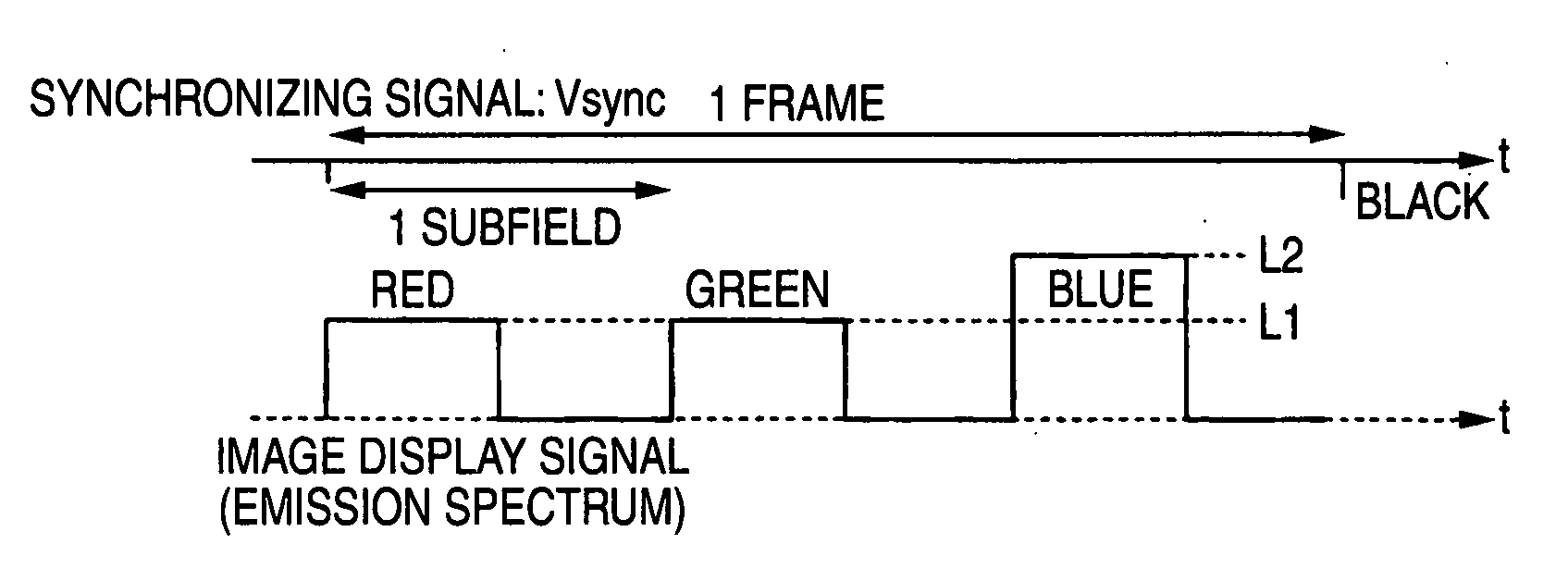

[0196]The lighting of the W light sources in the final subfield was not effected at the time of black display in Example 1 (variable gradation). The reproducible range of color at this time was the same, but the contrast ratio was 200:1.

example 3

[0197]The arrangement adopted was such that the LEDs of the B light sources were lit up in the final subfield in Example 1. When white and black display was effected, the light sources of the three colors of R, G, and B were lit up. When blue display was effected, the blue LEDs were lit up in the final subfield. The blue contrast ratio (blue CR) calculated from the ratio between the blue display luminance and the black display luminance improved from 700:1 to 1200:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com