Wall Exterior Structure for Outer Wall Heat-Insulated Building and Wall Exterior Base, Lateral Furring Frame for Wall Exterior Material Installation and Method for Covering Wall Using Lateral Furring Frame, and Exterior Base Material and Outer Wall Using Exterior Base Material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

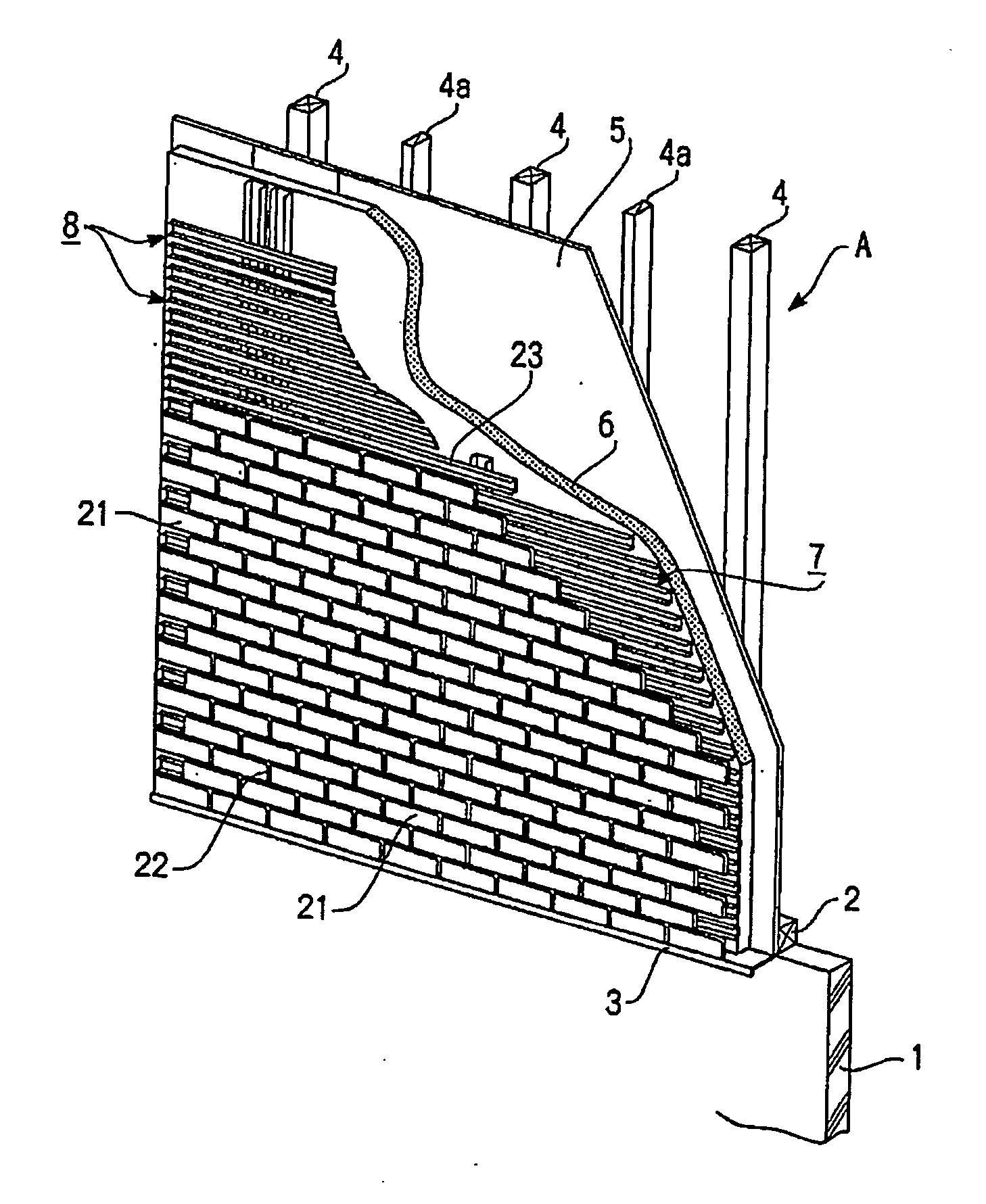

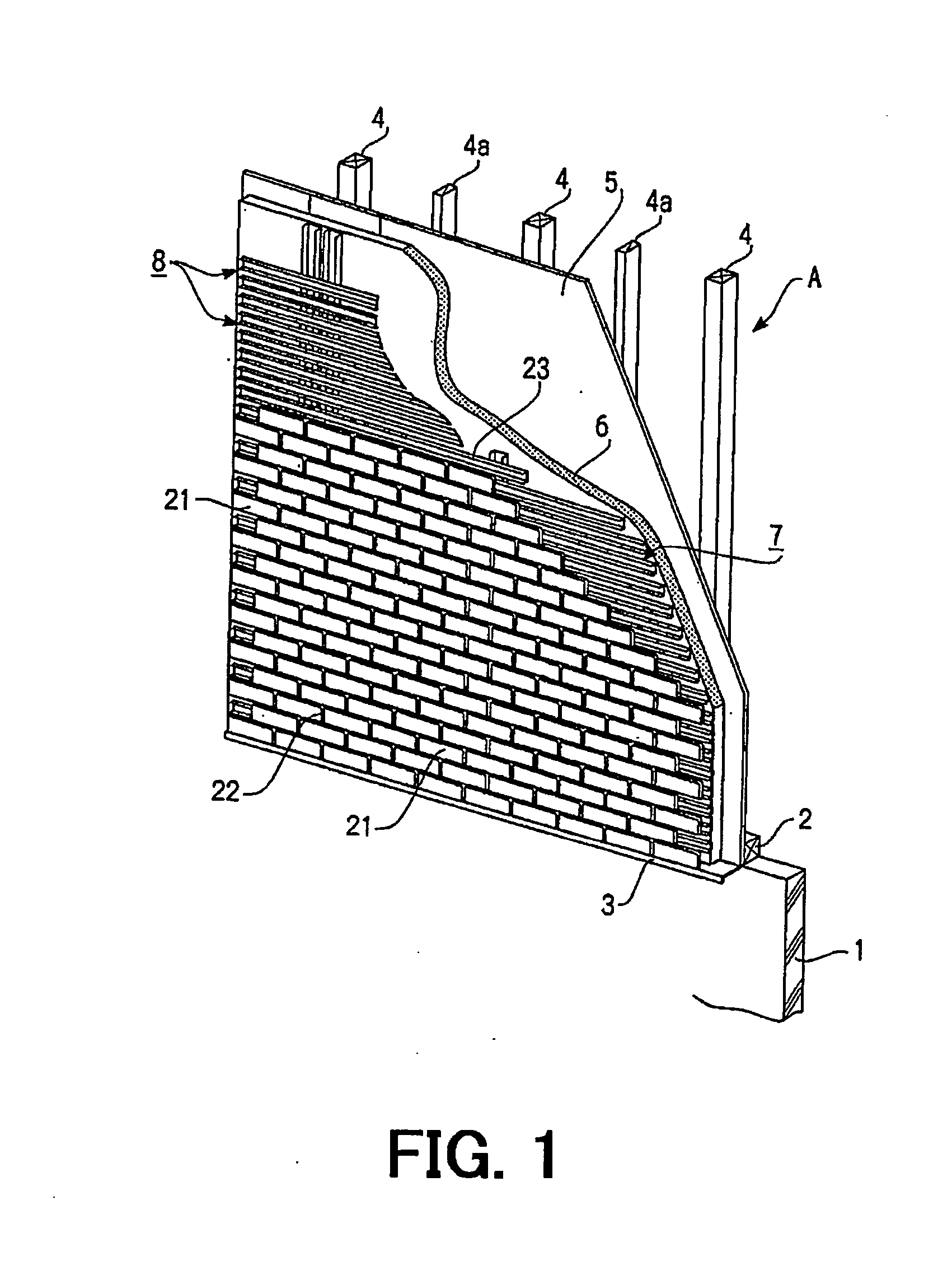

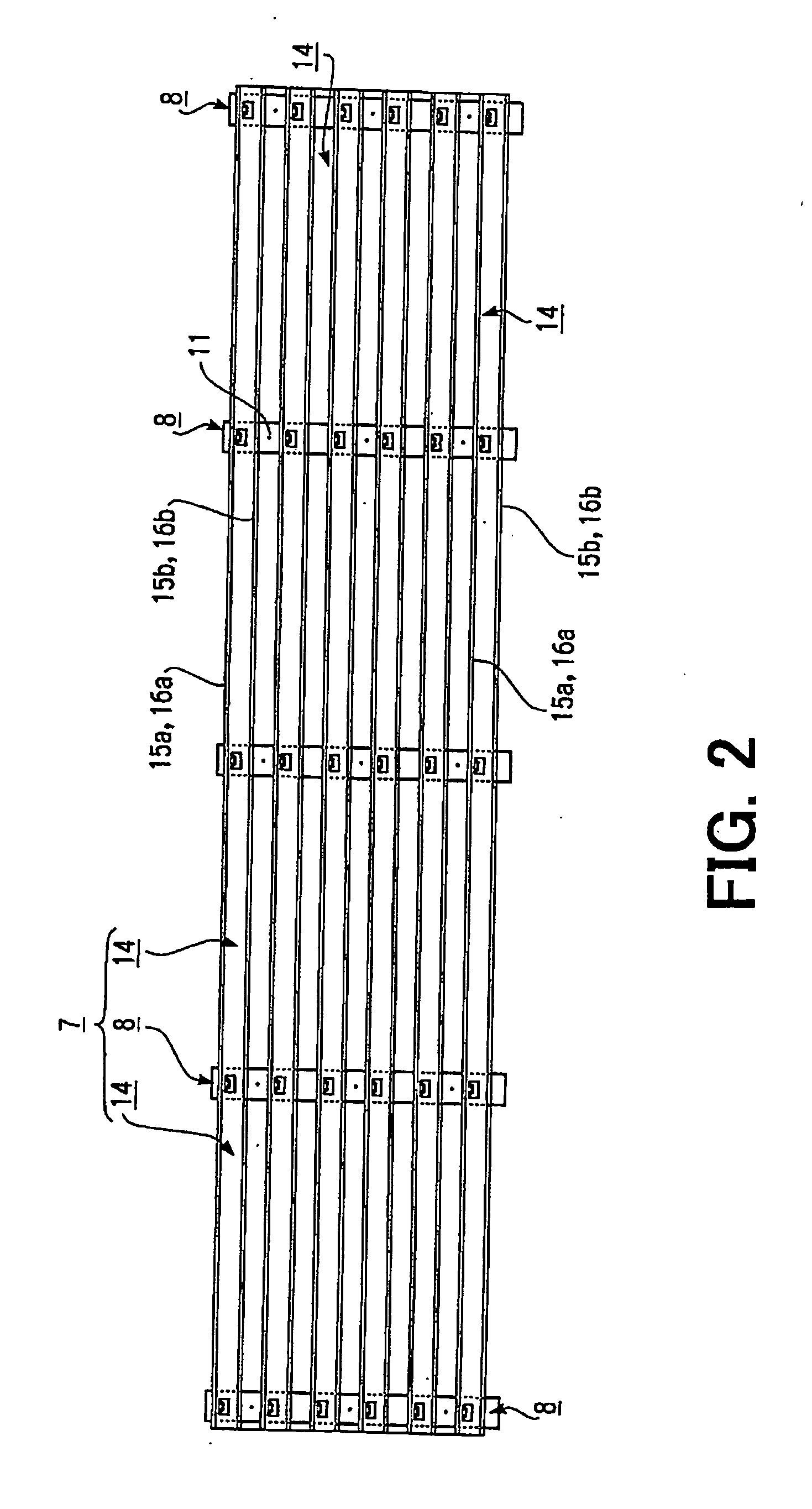

[0128] First, according to the first embodiment, a wall exterior structure and a wall exterior base, shown in FIGS. 1 to 12, will be explained below.

[0129] FIGS. 1 to 12 show various elements in an outer wall heat insulated building according to the first embodiment. FIG. 1 shows a single family house to which an outer wall portion A is heat insulated according to the wooden axial assembling construction method. The single family house includes a structural base 1 having its lower side embedded in the ground, a basic frame 2 fixed on the structural base 1 and from which a weather board 3 is extended out under a heat insulation structure, and plural main columns 4 and plural studs 4a planted on the basic frame 2.

[0130] The outer wall portion A is formed of a structural panel 5 (being a structural frame in a broader sense) overlying a required surface between the main column 4 and the stud 4a and an outer heat insulation layer 6 disposed over the structural panel 5. An exterior base...

second embodiment

[0153] Next, a wall exterior structure embedding the second embodiment of the present invention and a lateral furring strip for wall exterior including the wall exterior base will be explained by referring to FIG. 13 to FIG. 35.

[0154] The second embodiment belongs to the same line as the first embodiment and has so much in common with the first embodiment. Hence, the explanation becomes complicated. In the second embodiments shown in FIGS. 13 to 35, like numerals are attached to the same elements as those in the first embodiment. Thus, the explanation is simplified. The number of 100 is added to the corresponding numerals of main elements.

[0155] In the third embodiment, like numerals are attached to the same elements as elements in the first and third embodiments and the explanation is simplified. The number of 200 is added to the corresponding numerals of main elements.

[0156] In the second embodiment shows FIGS. 13 to 35, a metallic lateral furring strip frame 100a is formed of ...

third embodiment

[0160] Next, a wall exterior structure according to the third embodiment of the present invention and a wall exterior base thereof will be explained by referring to FIGS. 36 to 50.

[0161] In the third embodiment shows in FIGS. 36 to 50, a metallic rail unit frame 200a is formed of fourth vertical rails (vertical furring strips) 201 (hereinafter merely referred to as “vertical rails 201”), plural third standard lateral rails for unit formation (unit formation standard lateral furring strips) 202 (hereinafter merely referred to as “standard lateral furring strips 202 for unit formation”), plural third bridge short lateral rails (short lateral furring strips for bridging) (hereinafter merely referred to as “short lateral rails 203 for bridging), and plural third extension adjustment lateral rails (lateral furring strips for extension adjustment) 204 (merely referred to as “lateral rails 204 for extension adjustment”). Each fourth vertical rail 201 corresponds to the vertical furring st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com