Retaining frame for a support element of a sensor

a technology for supporting elements and sensors, which is applied in the direction of machine supports, furniture parts, vehicle cleaning, etc., can solve the problems of costing a new window, the cost of a very sophisticated sensor is incurred in addition to the distance between the support element and the sensor, and the retaining frame is near impossible to remove. , to achieve the effect of simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

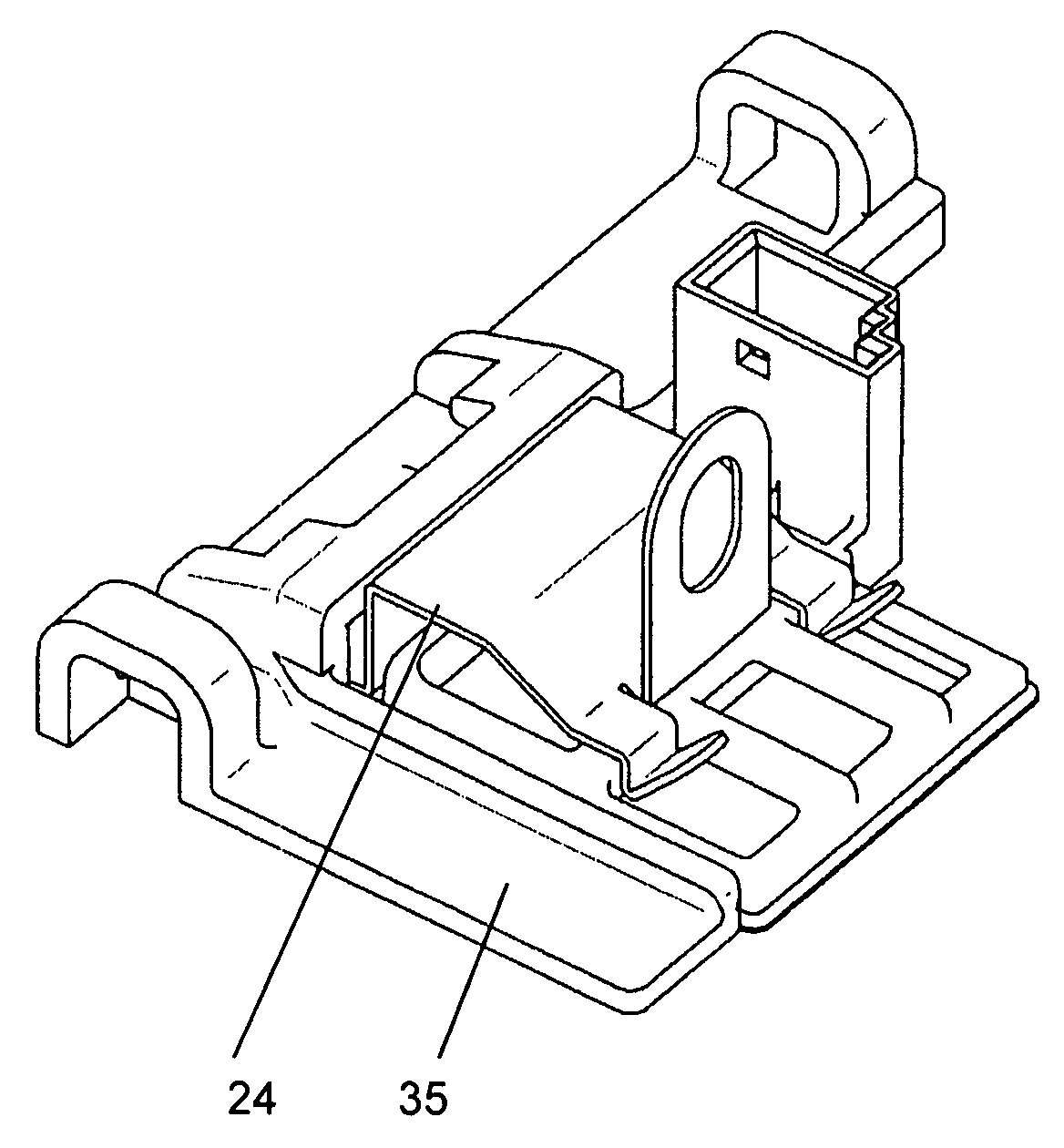

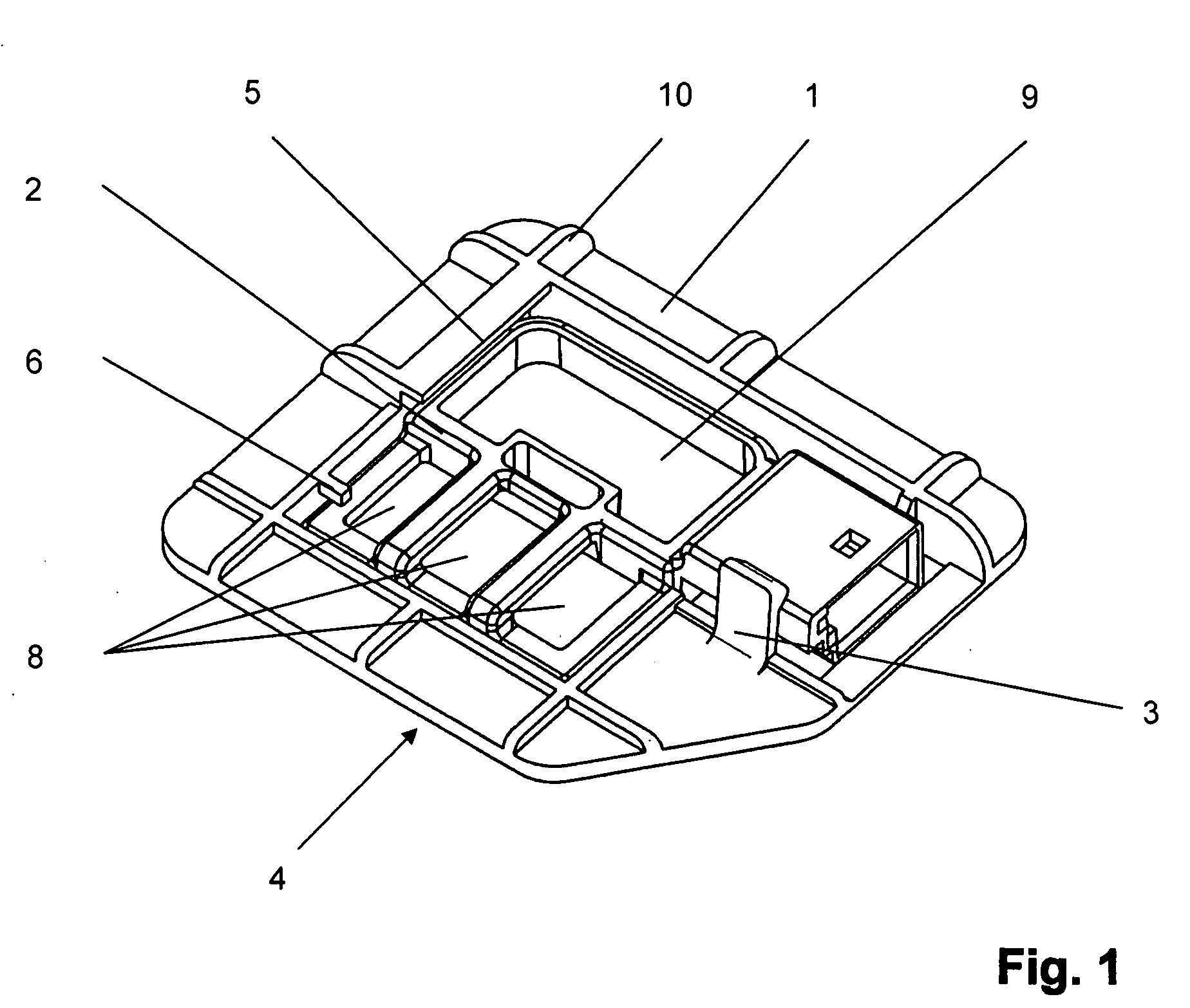

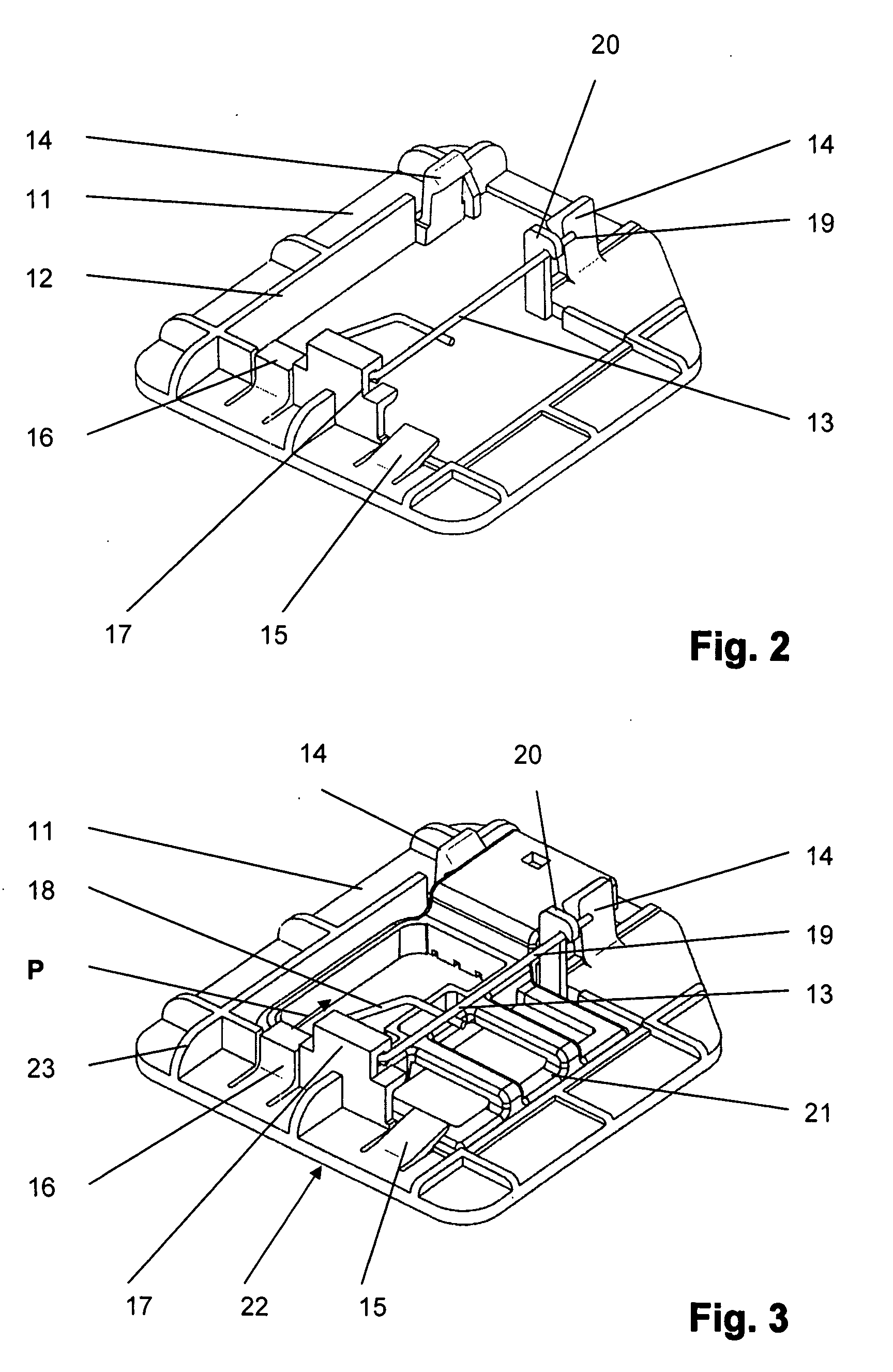

Embodiment Construction

[0022]FIG. 1 shows a retaining frame 1 with an installed support element 2 and an extension 3 that is molded onto the retaining frame 1 as a single piece. The retaining frame 1 has a flat underside 4 and a contact surface 5 against which the support element 2 can be positioned at installation. Also provided on the retaining frame 1 are projections 6 by means of which the support element 2 can be clamped into the retaining frame 1. Formed as a single piece with the support element 2 is a connecting element 7, wherein the connecting element 7 in this embodiment is designed as a receptacle for a plug. In addition, the support element 2 has openings 8 that make it possible for a sensor held in the support element 2 to also sense measured values in the vehicle passenger compartment. The sensor element is not shown in this embodiment. In this case, the sensor element would be below the support element 2 in the regions 9 and 8, directly on the window. The sensor can sit directly on the win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com