Lead-free glass material for use in sealing and, sealed article and method for sealing using the same

a technology of lead-free glass and sealing, applied in the field of lead-free glass material for use in sealing, can solve the problems of difficult recycling, inability to obtain fundamental measures, and contamination of soil, and achieve the effect of preferable sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

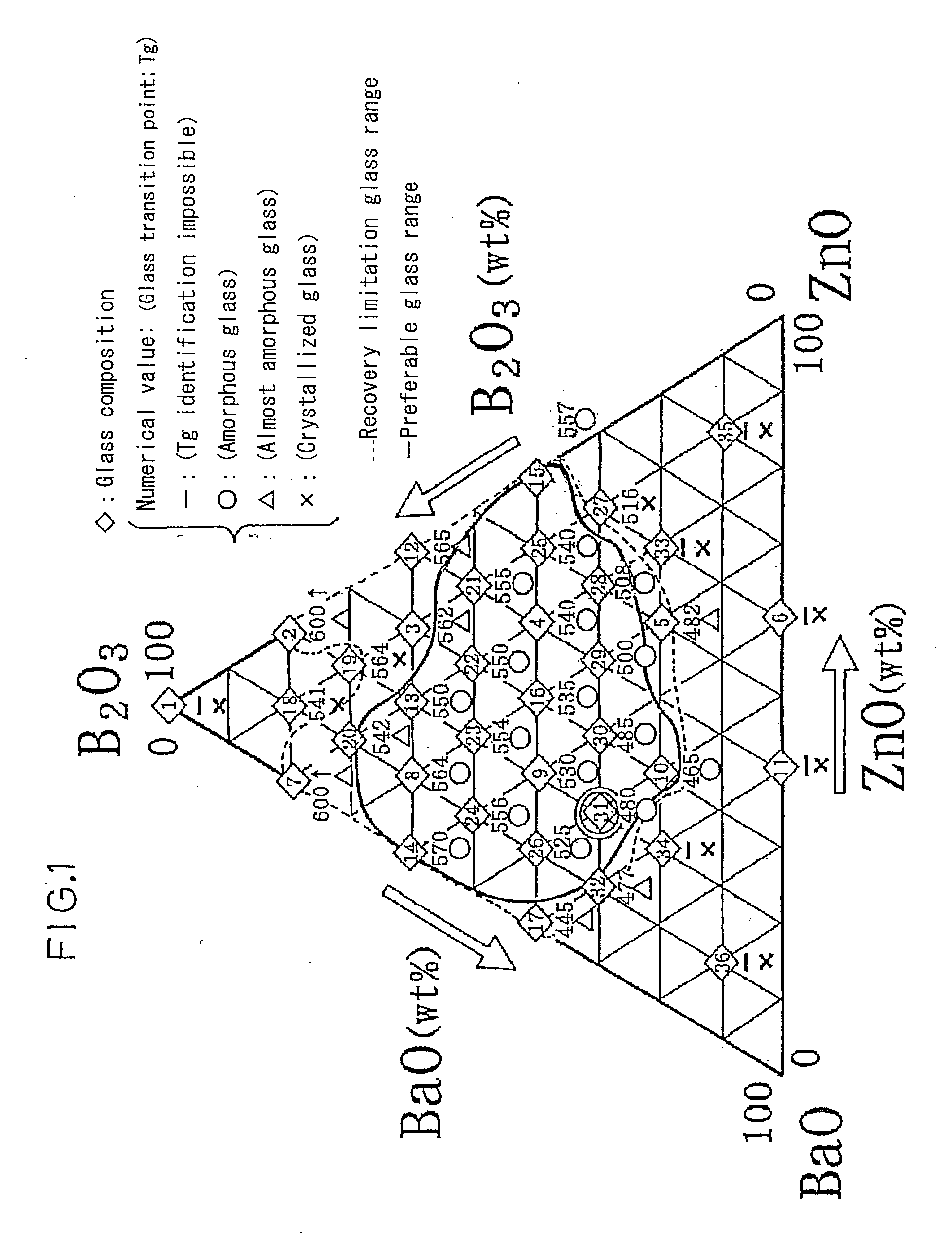

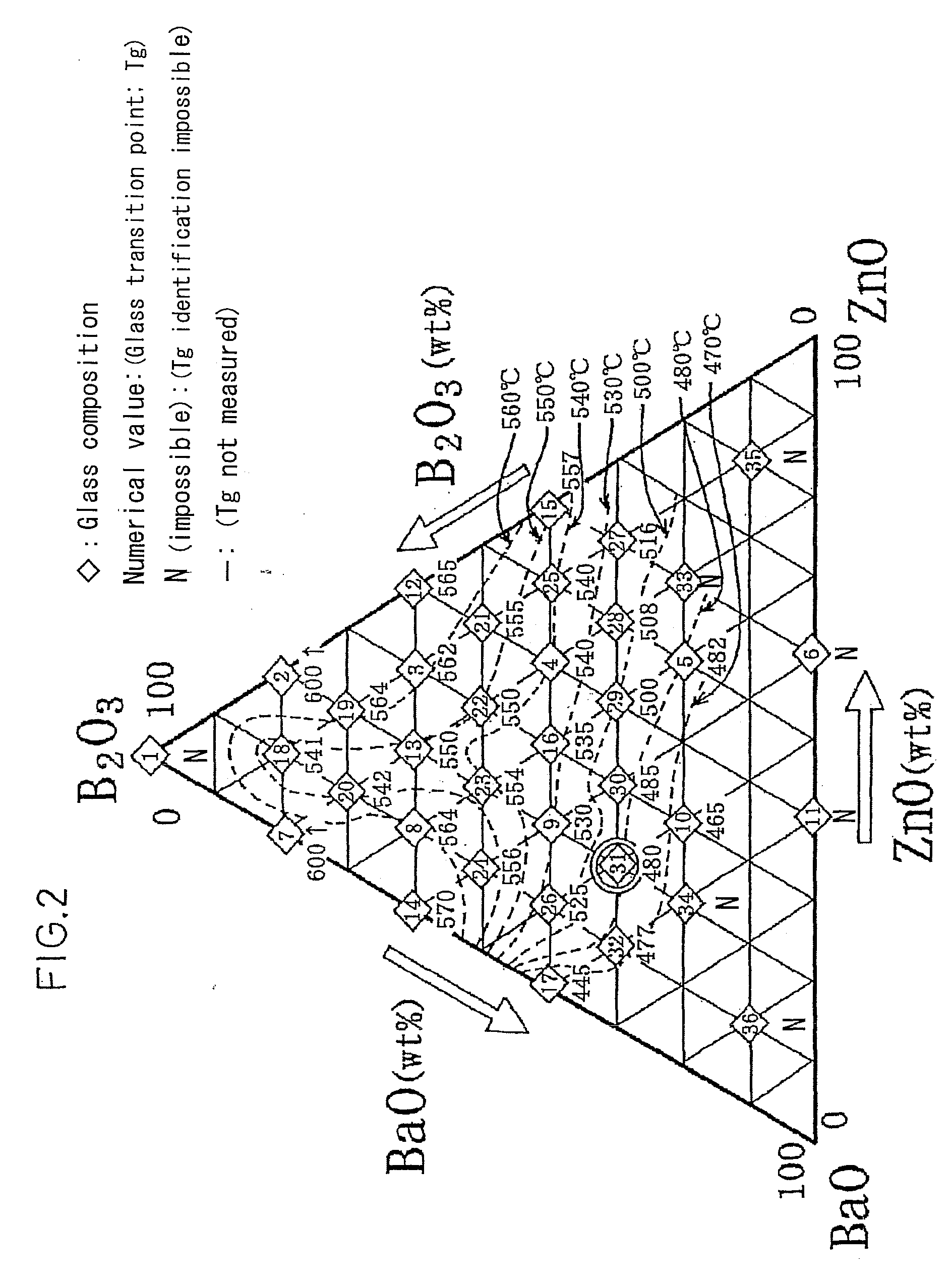

example 1

[0072] A mixture (total amount of 15 g) of B2O3 powder, ZnO powder and BaO powder as the material oxide at a ratio (% by weight) described in the following Table 1 was housed in a platinum crucible and burned in an electric furnace at approximately 1000° C. for 60 minutes, the molten material was cast into an alumina boat to create a glass rod, the glass rod was cooled in the atmosphere, then grinded with a stamp mill (ANS 143 made by Nitto Kagaku Co., Ltd) and classified to collect powder having a grain size smaller than or equal to 100 μm, and lead-free glass materials B1-B32 were manufactured.

[0073] [Glass Recovery Percentage and Visual Appearance Property]

[0074] In the lead-free glass material manufactured in the above Example 1, the glass recovery percentage was measured on the basis of the yield of casting of a molten material from the platinum crucible into the alumina boat and the visual appearance property of the molten material was checked. The results are shown in Table ...

example 2

[0090] A mixture (total amount of 15 g) of V2O5 powder, ZnO powder and BaO powder as the material oxide at a ratio (% by weight) described in the following Table 3 was housed in a platinum crucible and burned in an electric furnace at approximately 1000° C. for 60 minutes, the obtained molten material was cast into an alumina boat to create a glass rod, the glass rod was cooled in the atmosphere, then grinded similarly to the Example 1 and classified to collect powder having a grain size smaller than or equal to 100 μm, and lead-free glass materials V1-V34 were manufactured.

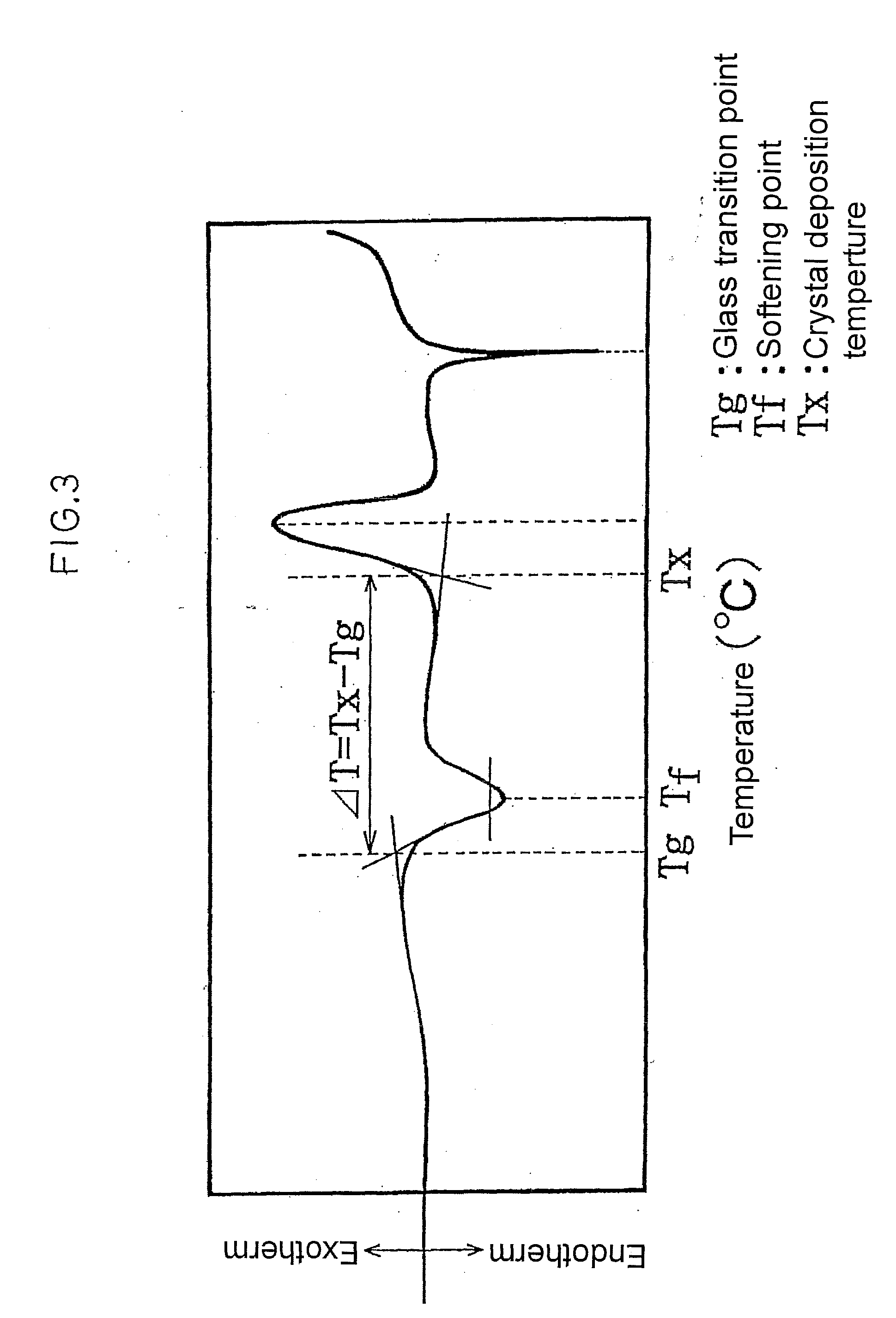

[0091] Regarding these lead-free glass materials V1-V34, the glass transition point Tg, the softening point Tf and the crystallization starting temperature Tx were measured similarly to Example 1 and the glass texture was checked by X-ray structural analysis. The results are shown in Table 3 together with ΔT (Tx−Tg) and the kind of the deposited crystal. It should be noted that the sign (−) in each column of Tg,...

example 3

[0094] B2O3 powder of 20 part by weight, V2O5 powder of 10 part by weight, ZnO powder of 20 part by weight and BaO powder of 50 part by weight were mixed as the material oxide, and burning, creation of a glass rod, grinding after cooling and classifying were performed similarly to Example 1 to manufacture a lead-free glass material BV. Here, the molten material after burning was of a tawny vitriform and preferable fluidity and preferable visual appearance were offered. Then, when the glass transition point Tg, the softening point Tf, the crystallization starting temperature Tx and the thermal expansion coefficient of this lead-free glass material BV were measured similarly to Example 1 and the glass texture was checked by X-ray structural analysis, the following result was obtained.

[Characteristic of Lead-Free Glass Material BV]Glass Transition Point Tg450° C.Softening Point Tf465° C.Crystallization Starting Temperature Tx550° C.Thermal Stability ΔT100° C.Thermal Expansion Coeffic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization starting temperature | aaaaa | aaaaa |

| crystallization starting temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com