Rtm molding method and device

a technology of resin transfer molding and molding method, which is applied in the direction of manufacturing tools, food shaping, drawing profiling tools, etc., to achieve the effects of reducing production costs, shortening molding time, and increasing production speed and production amoun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

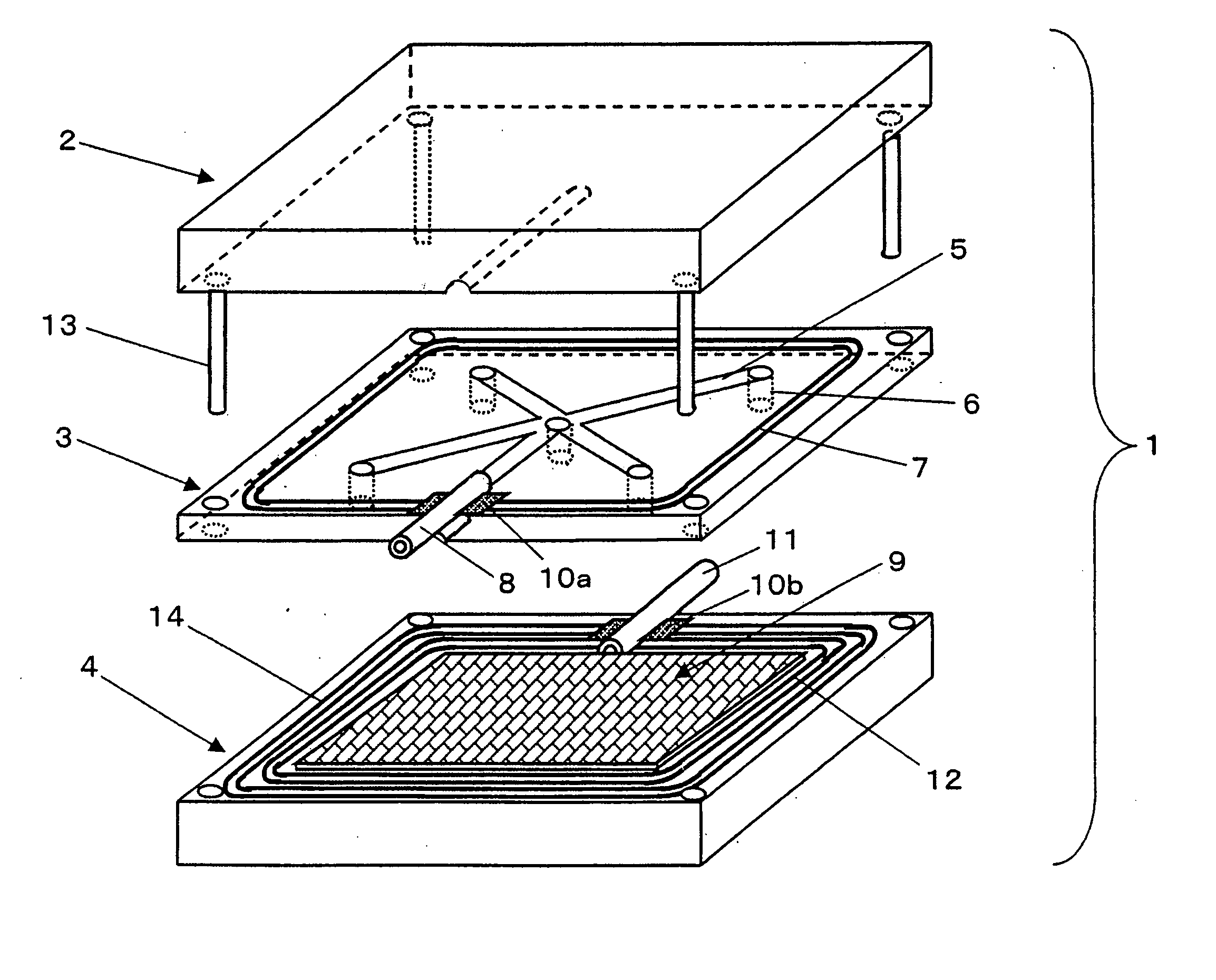

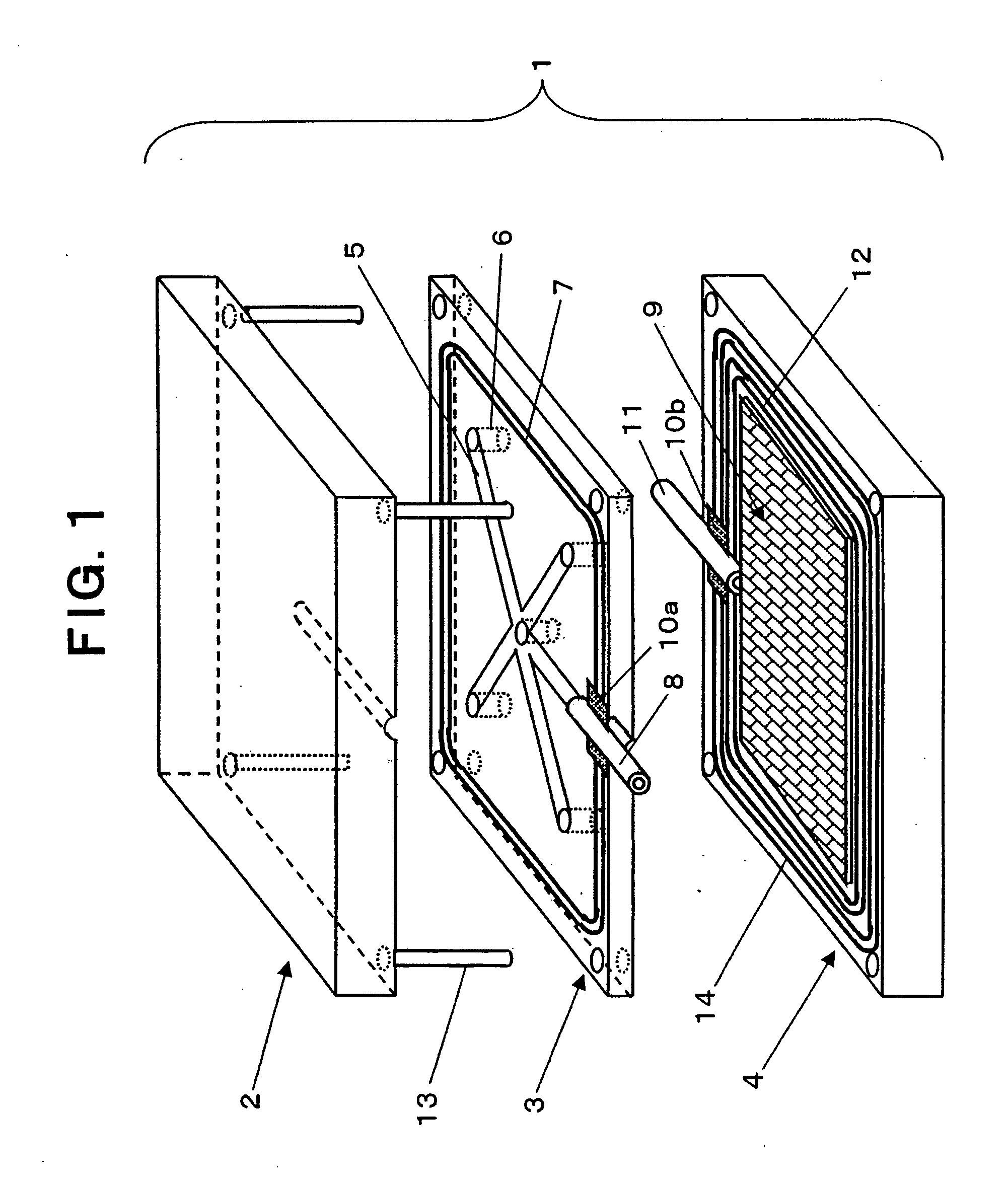

Method used

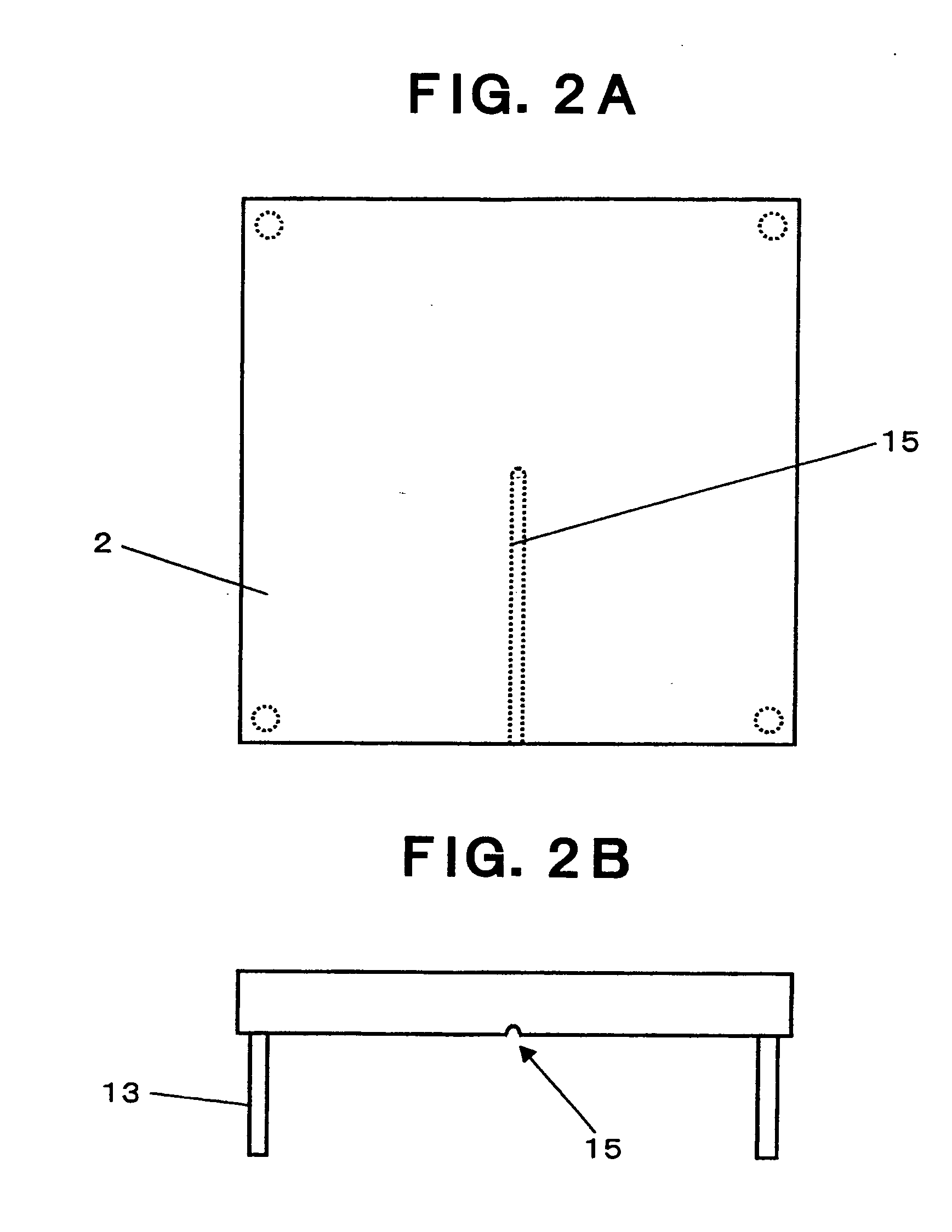

Image

Examples

example 1

[0191] In the above-described respective embodiments, when molding was carried out setting the size of a mold at 1500 mm×1200 mm×depth 3 mm at the molding surface (the cavity surface), using a laminate of 8 plies of “TORAYCA” T700 cloth BT70-30 (300 g / m2) produced by Toray Industries, Inc. as the reinforcing fiber substrate, and using a high-speed curing type epoxy resin (main ingredient: “Epicoat”828 (an epoxy resin produced by Yuka Shell Epoxy Corporation), curing agent: blend TR-C35H (an imidazole derivative) produced by Toray Industries, Inc.) as the resin, in spite of a relatively large molded product, a good and quick molding could be carried out. Where, the time for completing the impregnation of the resin into the substrate was 5 minutes or less at a resin injection pressure of 0.7 MPa, and could be shortened down to ⅕- 1 / 10 or less of a conventional method.

[0192] FIGS. 8 to 12 show RTM molding method and device according to the second embodiment of the present invention. F...

example 2

[0212] In the RTM molding system 54 according to this embodiment shown in FIG. 11, as an example of molding at molding conditions according to the present invention, an example of molding of a large flat plate (length of 1600 mm×width of 700 mm×height (thickness) of 2 mm) will be explained. The whole of the RTM mold 41 used in this example is shown in FIGS. 8 and 9, and the relationship between the temperature and the viscosity of the resin used for the molding and the property in resin curing degree-time at the molding temperature are shown in FIG. 12A and FIG. 12B, respectively. On the molding cavity portion 50 provided on the lower die 43 of the mold 41 (length: 2000 mm, width: 1000 mm and height: 350 mm in each of upper die 42 and lower die 43) having resin injection tubes 46 to 48 and discharge tube 49, carbon fiber “TORAYCA” cloth (CO6343B: T300B-3K, weight: 192 g / m2) is laminated by 8 plies (0 / 90° oriented substrates: 4 plies, ±45° oriented substrates: 4 plies), a preform sub...

example 3

[0226] Although the above-described Example 2 employed a single plate structure of reinforcing fiber substrate, as another example, when employed was a carbon fiber reinforcing structural material including a foam core (thickness: 10 mm, apparent specific gravity: 0.1) therein (three plies of the above-described carbon fiber “TORAYCA” cloths were stacked on each of the upper and lower surfaces of the foam core), an almost similar molded product excellent in surface quality could be obtained. Where, the time for impregnation was about 4.5 minutes, and was a short period of time similarly to the above-described example.

[0227] Next, an RTM molding method according to a third embodiment of the present invention will be explained. First, the production of the fiber reinforced resin molded by this RTM molding method will be explained referring to FIG. 18. As shown in FIG. 18A, a resin injection port 85 and a suction port 86 are provided on an upper die 83 of the double-sided mold. Lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com