Downflow knockback condenser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

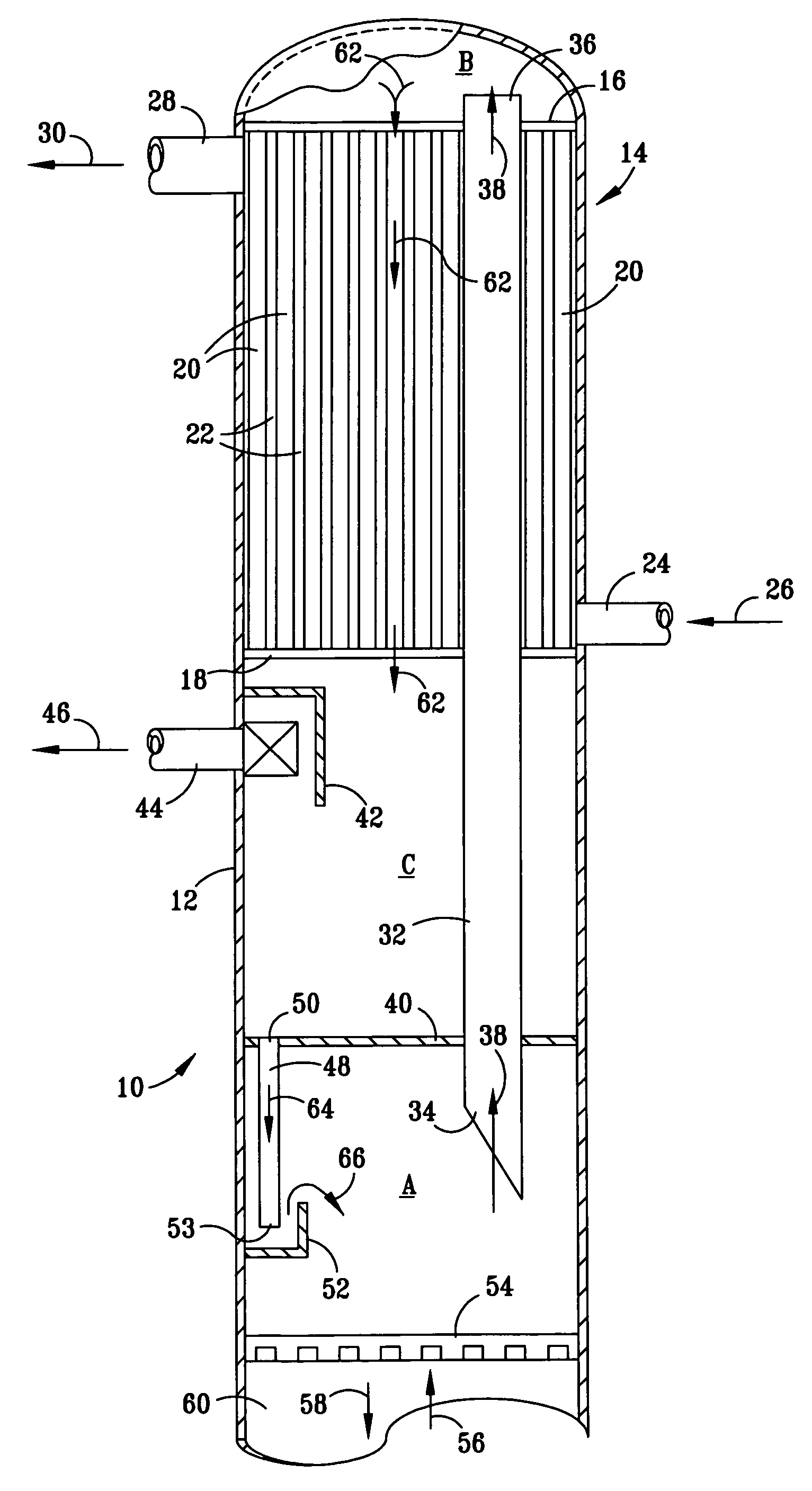

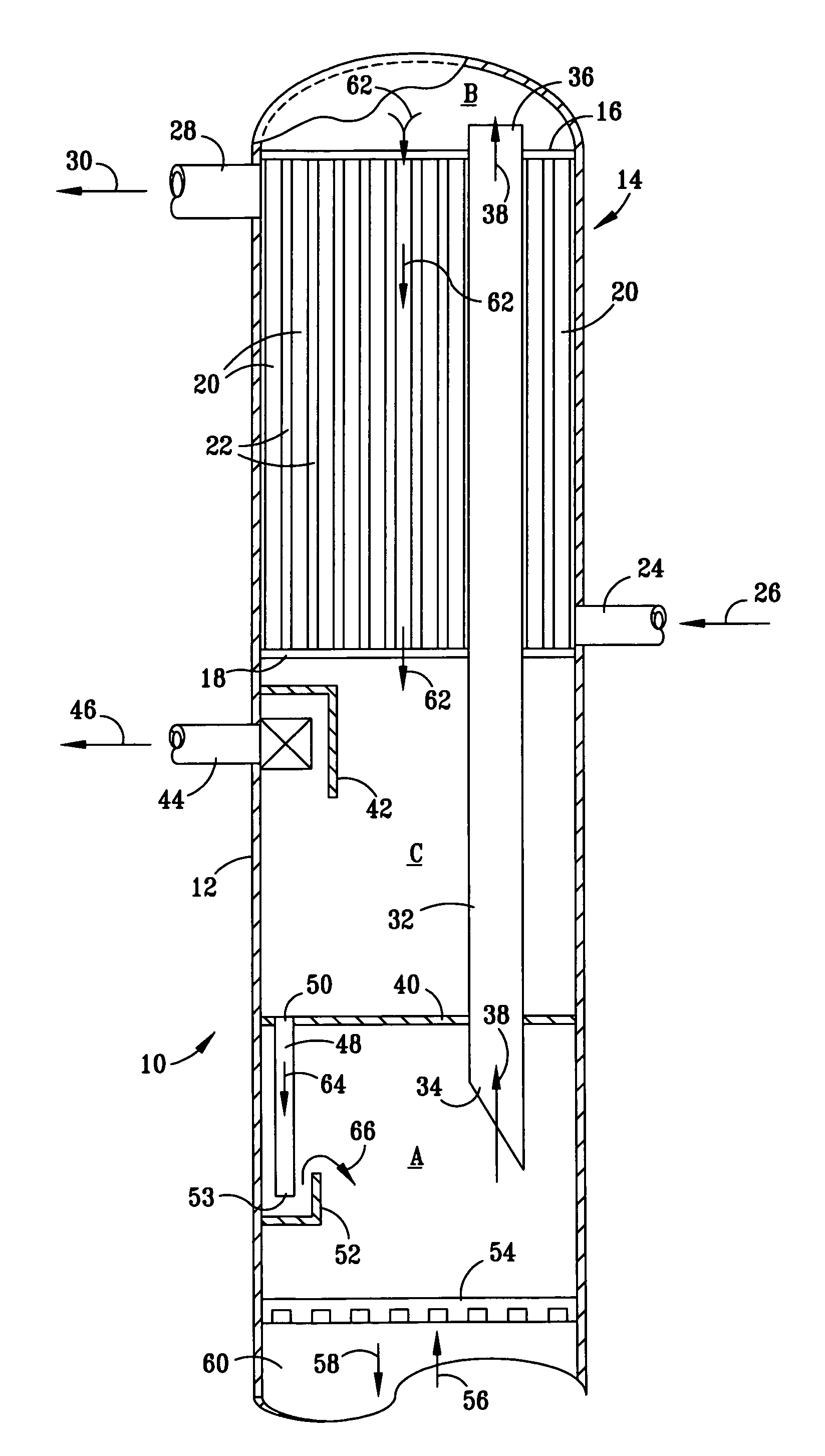

[0014] The drawing depicts the upper portion of a fractionation tower 10 in which the upper portion of shell 12 contains a preferred embodiment of downflow, knockback condenser 14 of the invention. Fractionation tower 10 is preferably made of conventional materials capable of operating at the temperatures and pressures needed for a particular application, and has a nominal diameter ranging from about 18 to about 120 inches, depending upon plant size and throughput. Generally speaking, the fractionation section of fractionation tower 10 is disposed below section 60, and is broken away to facilitate enlargement of the upper section of the tower in which condenser 14 resides. As shown in the embodiment depicted in the drawing, section 60 of fractionation tower 10 is separated by liquid distribution plate 54 from the gas and condensed liquid recovery zones disposed between section 60 and condenser 14. Liquid distribution plate 54 allows rich vapor 56 rising upwardly from the fractionati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com