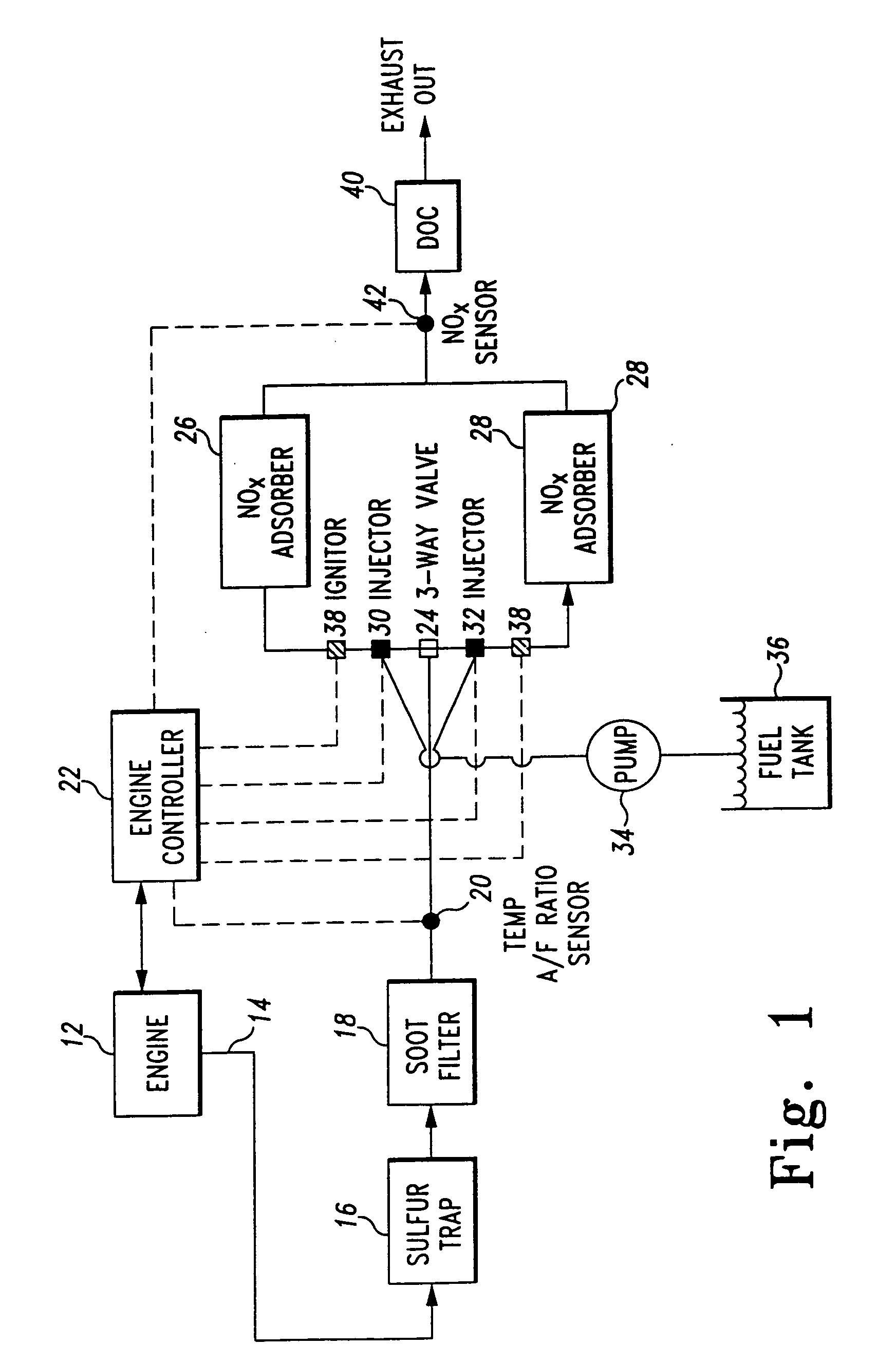

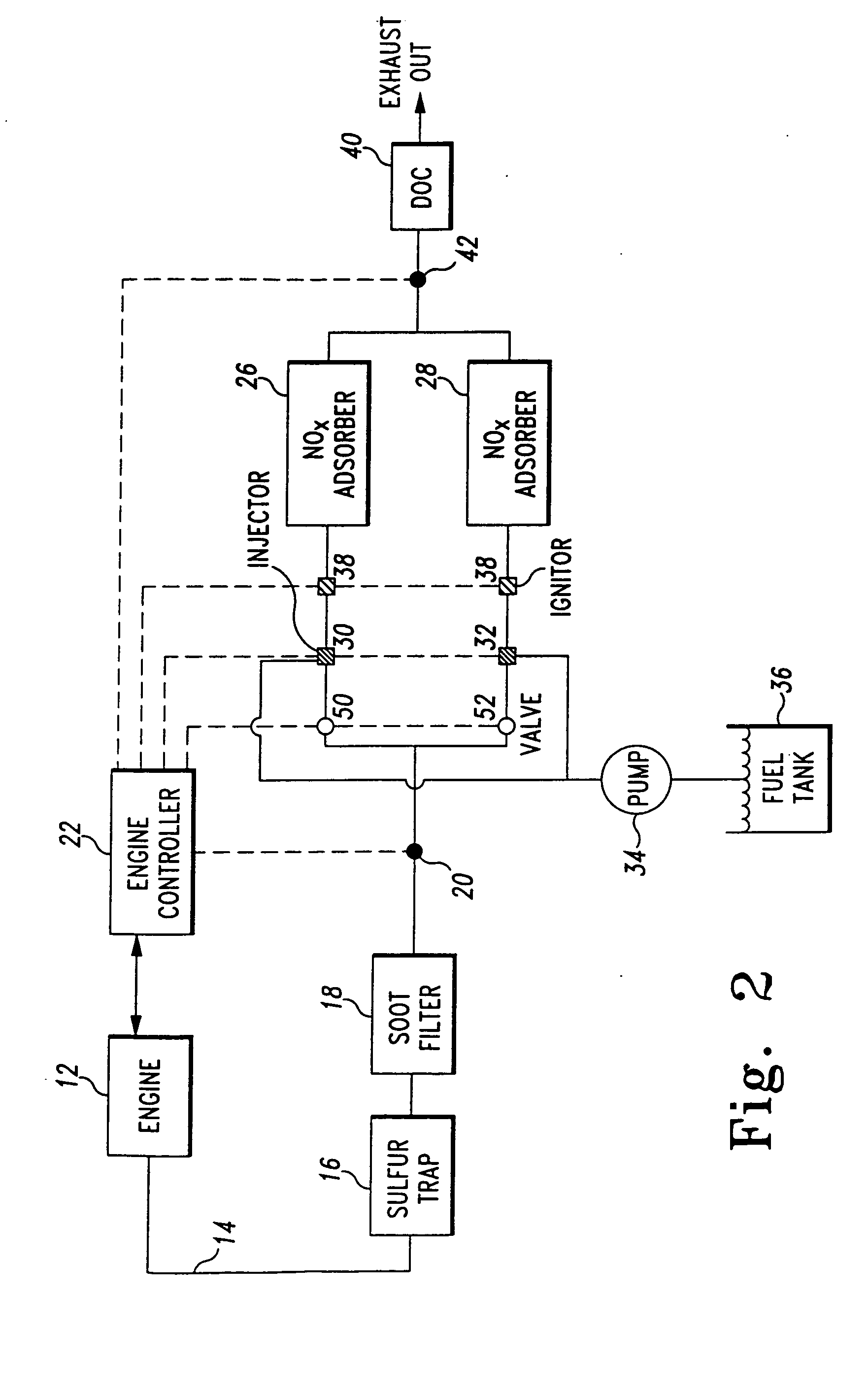

NOx adsorber aftertreatment system for internal combustion engines

an aftertreatment system and nox technology, applied in the field of internal combustion engines, can solve problems such as temperature rise, and achieve the effects of increasing temperature, reducing the amount of nox adsorber, and increasing the time and surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

fourth embodiment

[0050] As discussed hereinabove, catalytic soot filters 18 require high temperatures in order to regenerate. It is difficult to attain these high temperatures in the exhaust stream during low load operation of the engine 12. Under these conditions, the soot filter 18 eventually becomes clogged with soot. By placing the soot filter 18 upstream from the adsorber 26 and downstream from the fuel injector 30 as shown in the fourth embodiment, the catalytic soot filter 18 also receives the injected hydrocarbon and is regenerated by combustion of this hydrocarbon. Placement of the catalytic soot filter 18 in this position also provides more time and surface area for the introduced hydrocarbon to react with oxygen, thereby more completely burning the hydrocarbon. More complete hydrocarbon combustion will possibly eliminate the need for the diesel oxidation catalyst 40, thereby reducing exhaust system cost and package size.

[0051] Furthermore, the catalytic soot filter 18 will reformulate som...

fifth embodiment

[0053] As discussed hereinabove, catalytic soot filter 18 requires high temperatures in order to regenerate. It is difficult to attain these high temperatures in the exhaust stream during low load operation of the engine 12. Under these conditions, the soot filter 18 eventually becomes clogged with soot. By placing the soot filter 18 downstream from the adsorber 26 as shown in the fifth embodiment, heat generated in the adsorber 26 due to the combustion of the introduced hydrocarbon serves to raise the temperature of the catalytic soot filter 18 sufficiently to accomplish regeneration.

[0054] Furthermore, any hydrocarbon that slips unburned through the adsorber 26 will oxidize in the soot filter 18, thereby generating further heat to encourage regeneration of the soot filter 18. Because the hydrocarbon slip is oxidized in the soot filter 18, the diesel oxidation catalyst 40 of the prior embodiments is no longer required. Elimination of the diesel oxidation catalyst 40 reduces the exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com