Polymeric package with resealable closure and valve and methods relating thereto

a polymer and resealable technology, applied in the direction of packaging, packaging by pressing/gasifying, sacks, etc., can solve the problems of inability to achieve air tightness, gaps in profile seals, and rarely perfect engagement of sealing structures in bags utilizing resealable closures, etc., to facilitate the development of stand-off structures, facilitate the sealing of evacuable packages, and facilitate the effect of non-embossed portions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

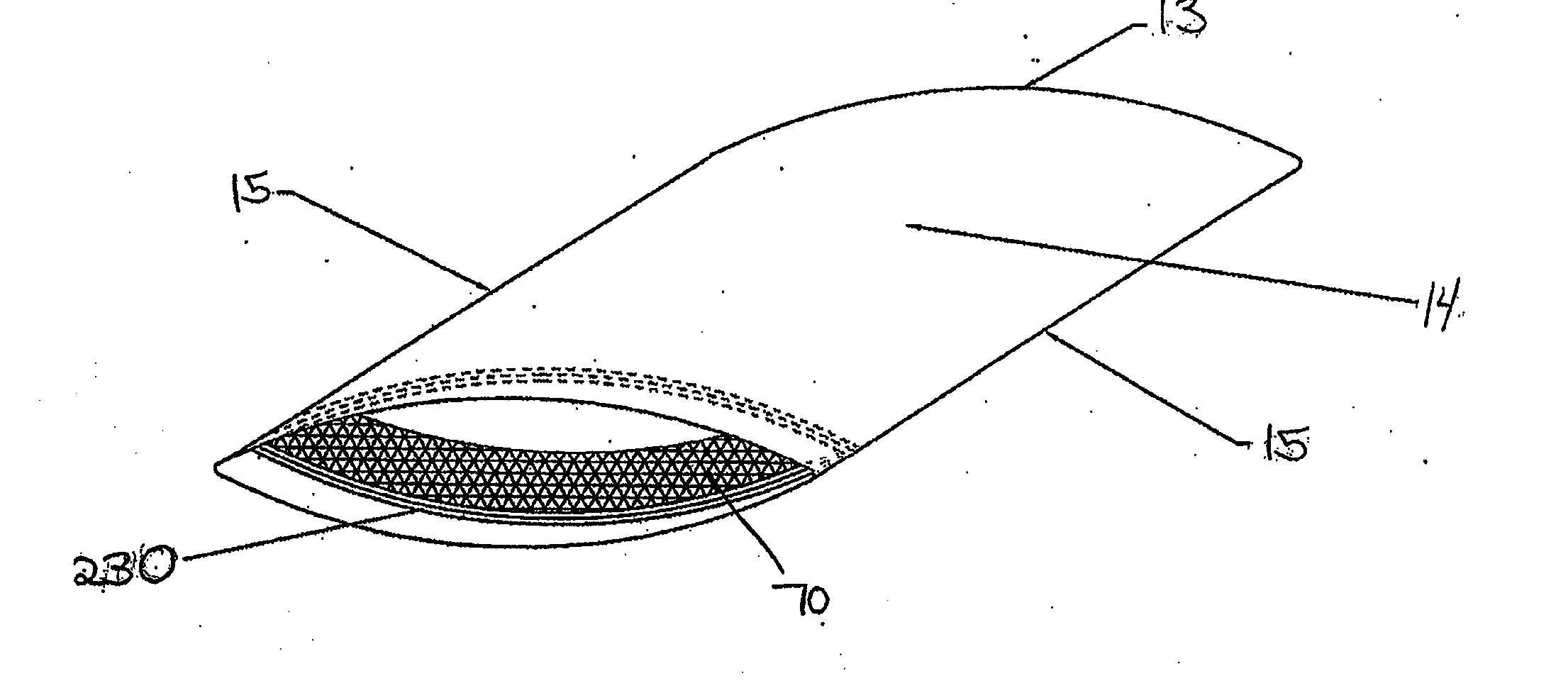

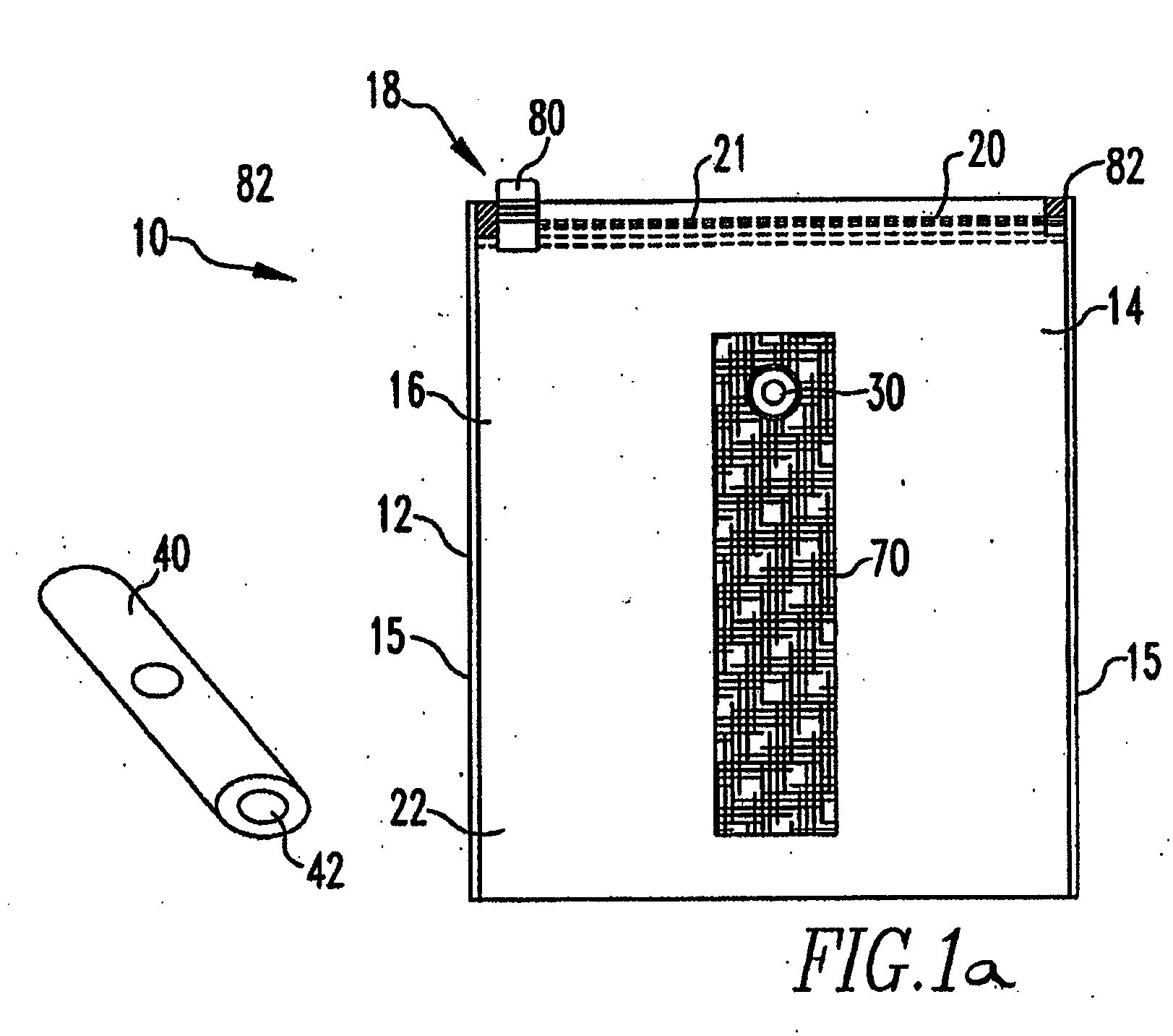

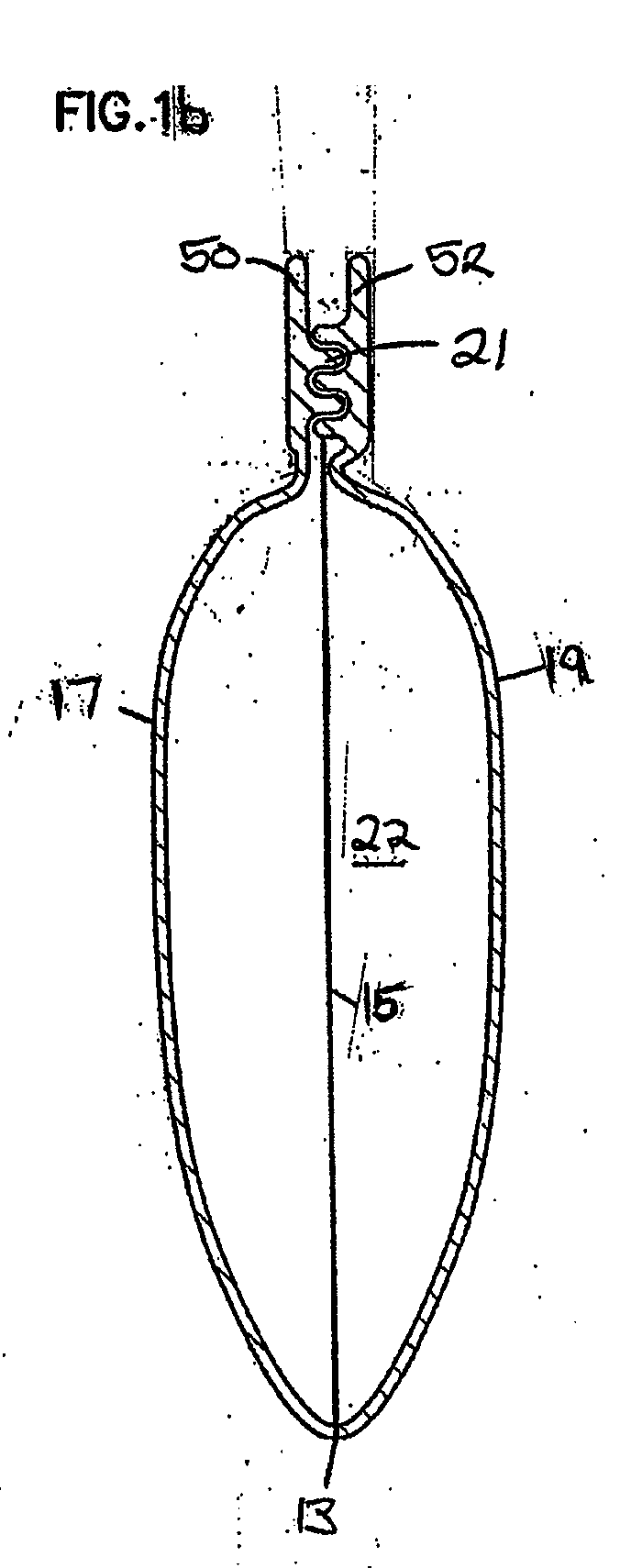

Embodiment Construction

[0055] The present invention is now discussed in more detail referring to the drawings that accompany the present application. In the accompanying drawings, like and / or corresponding elements are referred to by like reference numbers. In one embodiment of the present invention, a vacuum system is provided that may include a portable vacuum pump and an evacuable package in communication through a vacuum conduit. The evacuable package may optionally include a stand-off structure and a resealable closure having a caulking composition disposed thereon. In one embodiment, the resealable closure comprises interlocking profiles on which the caulking composition is disposed to provide a gas permeation resistant seal in the resealable closure. The vacuum conduit provides communication between the portable pump and the storage portion of the evacuable bag, wherein the vacuum conduit comprises at least a valve assembly and optionally a stand-off structure. In one embodiment, the stand-off stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com