Apparatus and method for generating hydrogen from water

a technology of apparatus and water, applied in the field of apparatus, can solve the problems of high cost of coal hydrogen production, inability to meet the requirements of the application,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

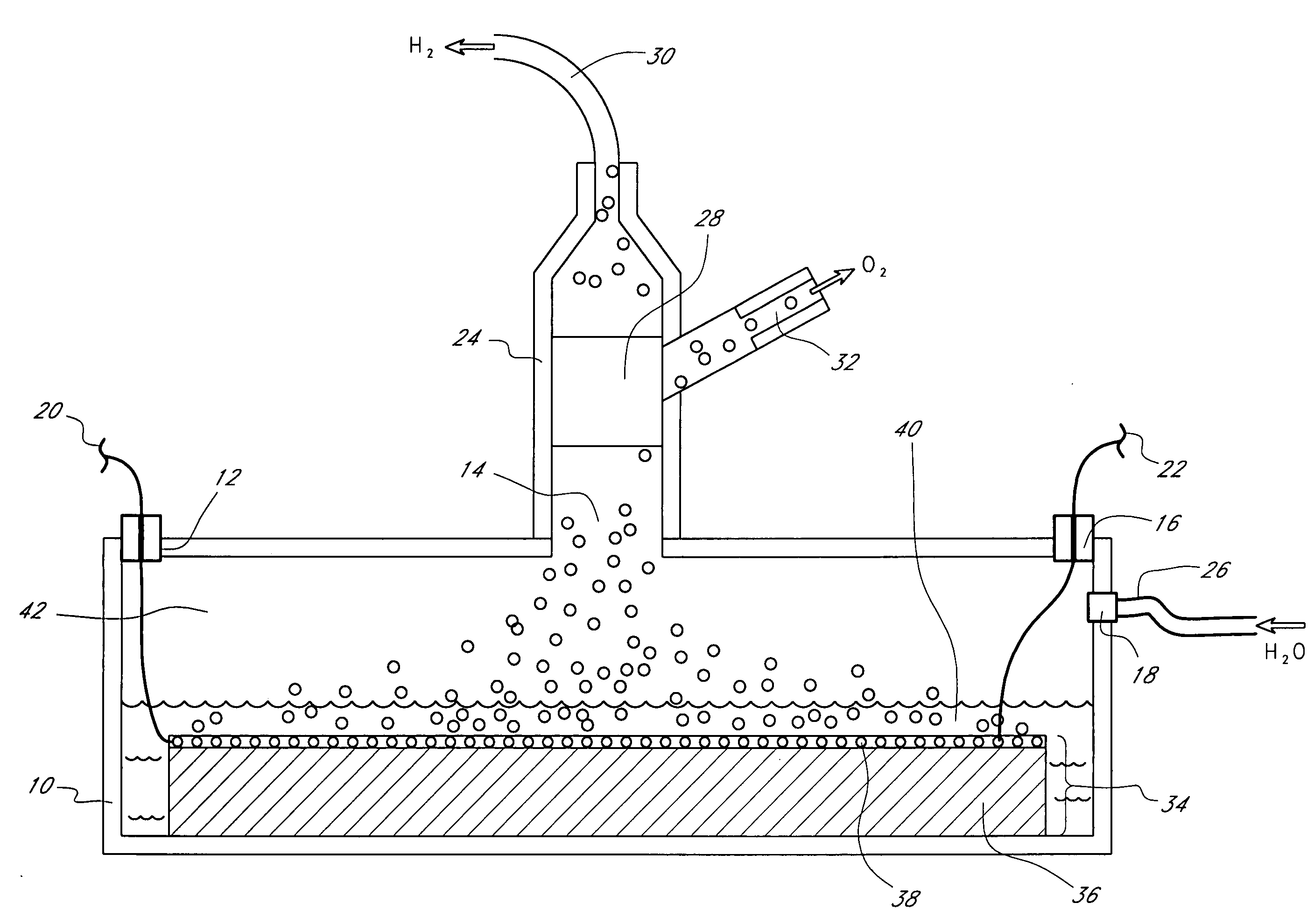

Image

Examples

example 1

[0051]A cell was made using a one liter Pyrex vessel (7 inch diameter) as the container. The electrolysis assembly included a single magnet having a single electrode pair placed directly on one broad face of the magnet, while the other broad face of the magnet rested in an aluminum tray to protect the magnet material from physical damage. The magnet was a 4.5 inch (diameter) by ½ inch (height) cylindrical NdFeB magnet with a residual induction (Br) of 12,300 gauss and an approximate 200 pound pull. The electrodes were 4.5 inch diameter sheets of galvanized steel or iron wire mesh in which the wires of the mesh had a diameter of 0.075 inch, and the wires in the mesh were positioned to create square openings 0.2 inch on each side. An insulator was positioned between the electrodes, wherein the insulator was a 0.075 inch thick 4.5 inch diameter piece of plastic mesh having square openings in the mesh that were 1 inch on each side. Each of the two electrodes had a piece of mesh about 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com