Cast glass-coated microwire for X-ray protection

a micro-wire and glass coating technology, applied in the field of radiation shielding materials, can solve the problems of insufficient glass wetting ability of '436 alloy for providing micro-wire manufacturing process, inability to provide micro-wire protection, and inability to absorb x-rays effectively, so as to achieve superior protection against x-ray radiation and high effective absorption of x-rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

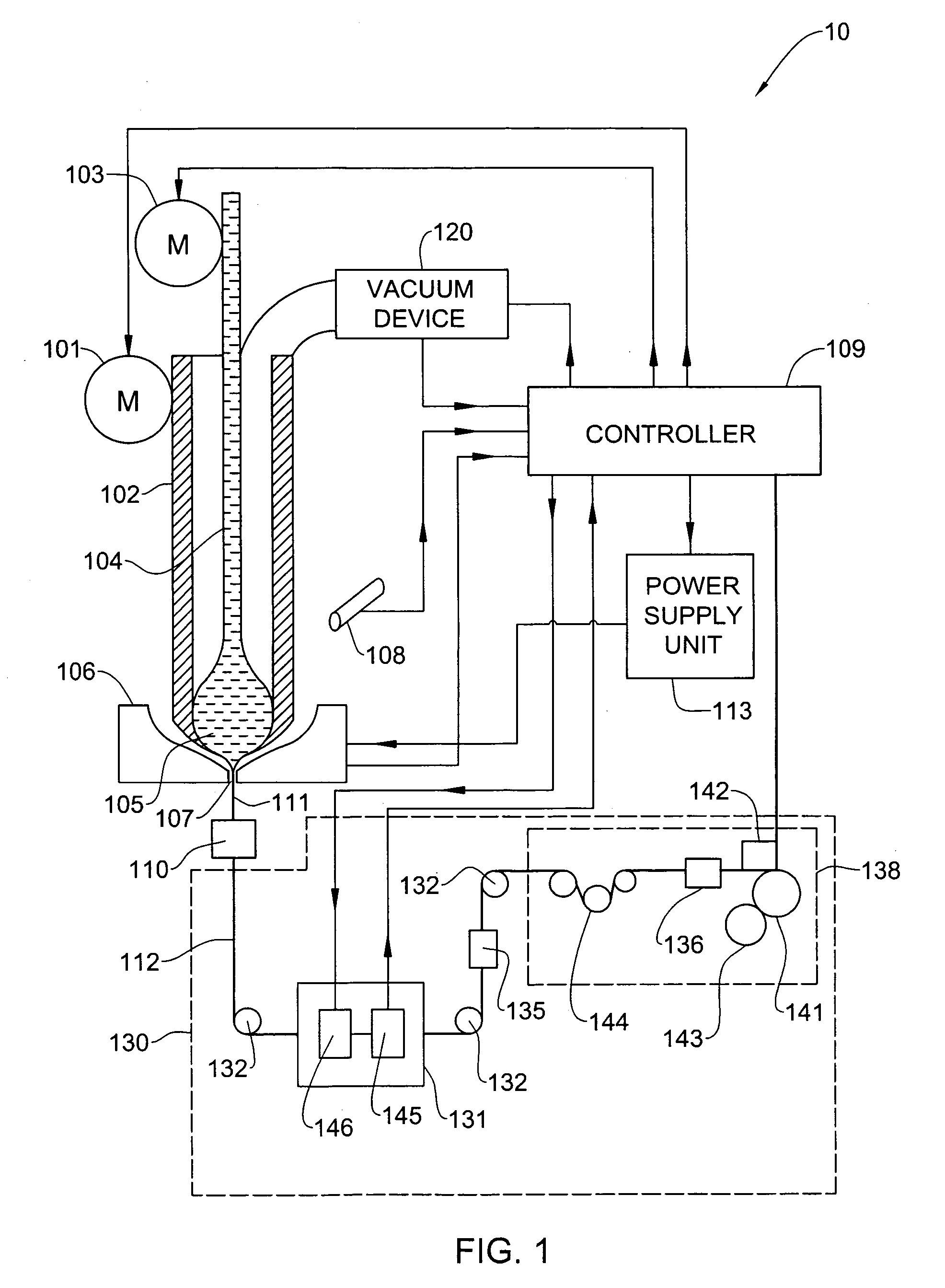

Image

Examples

examples

[0048] The microwires of the alloys according to the present invention were investigated. The microwires have the following compositions:

[0049] Microwire 1:

Metallic alloy (weight %)Glass (mol. %)Bi-21.0SrO12.0Sn-8.0B2O310.7In-4.0Al2O32.0Cu-3.5SiO25.3Si-0.6ZnO1.7Ce-0.05Li2O1.1Pb-62.85SnO3.0K2O4.0PhO43.7

[0050] Microwire 2

Metallic alloy (weight %)Glass (mol. %)Bi25.0SrO12.0Sn12.0B2O310.7In6.0Al2O32.0Cu4.5SiO25.3Si1.5ZnO1.7Ce1.2Li2O1.1Pb49.8SnO3.0K2O4.0PbO43.7

[0051] The diameter of the metal was 25 μm and the glass coating was 2-4 μm thick. The X-ray mass attenuation coefficient was measured at different wavelengths. Table 3 presents the results of the experiments.

TABLE 3λ, Å1.2430.9530.7830.7100.6210.4140.3110.2491.207μ / ρ, cm2 / g18610523220413042.823.213.58.2microwire 1μ / ρ, cm2 / g17910121819211238.921.311.98.0microwire 2λ, Å0.1550.14130.1400.1240.1200.0830.0620.0420.0311μ / ρ, cm2 / g3.82.411.97.47.03.61.40.70.4microwire 1μ / ρ, cm2 / g3.82.311.47.26.63.41.350.60.3microwire 2

[0052] The tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com