Aerated frozen suspensions with adjusted creaminess and scoop ability based on stress-controlled generation of superfine microstructures

a superfine microstructure and scooping ability technology, applied in frozen sweets, food science, application, etc., can solve the problems of ice crystal growth during cooling/hardening being claimed to be restricted, poor scooping ability, etc., and achieve the effect of most positively influencing scooping ability and creaminess characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0032] In a typical ice cream recipe with total dry matter content of about 40% (related to total mass) and 60% of water, a total freezable water fraction of 75% (cg′=0.75; related to the pure water phase) is equivalent to 45% of maximum frozen water content related to the total mass. If in such a system 50% of the freezable water are frozen, this is consequently equivalent to 22.5% of frozen water, related to the total mass. If the total non-dissolved solids fraction is calculated related to the total mass about 10% of fat globules / fat globule aggregates have to be added to the disperse ice crystal fraction of 22.5% (for this example). Such a slurry containing 32.5 weight % (=equal to about 32.5 volume % due to the density of the solids close to water density) of disperse phase is a highly concentrated suspension in which the solid particles sterically interact with each other if a shear flow is applied.

[0033] If such a concentrated suspension is additionally aerated with typicall...

example 2

[0045] In the following using ice cream as a typical aerated frozen slurry example, the structure criteria given before as well as the relationship to the sensory characteristics of scoop ability and creaminess shall be exemplary described.

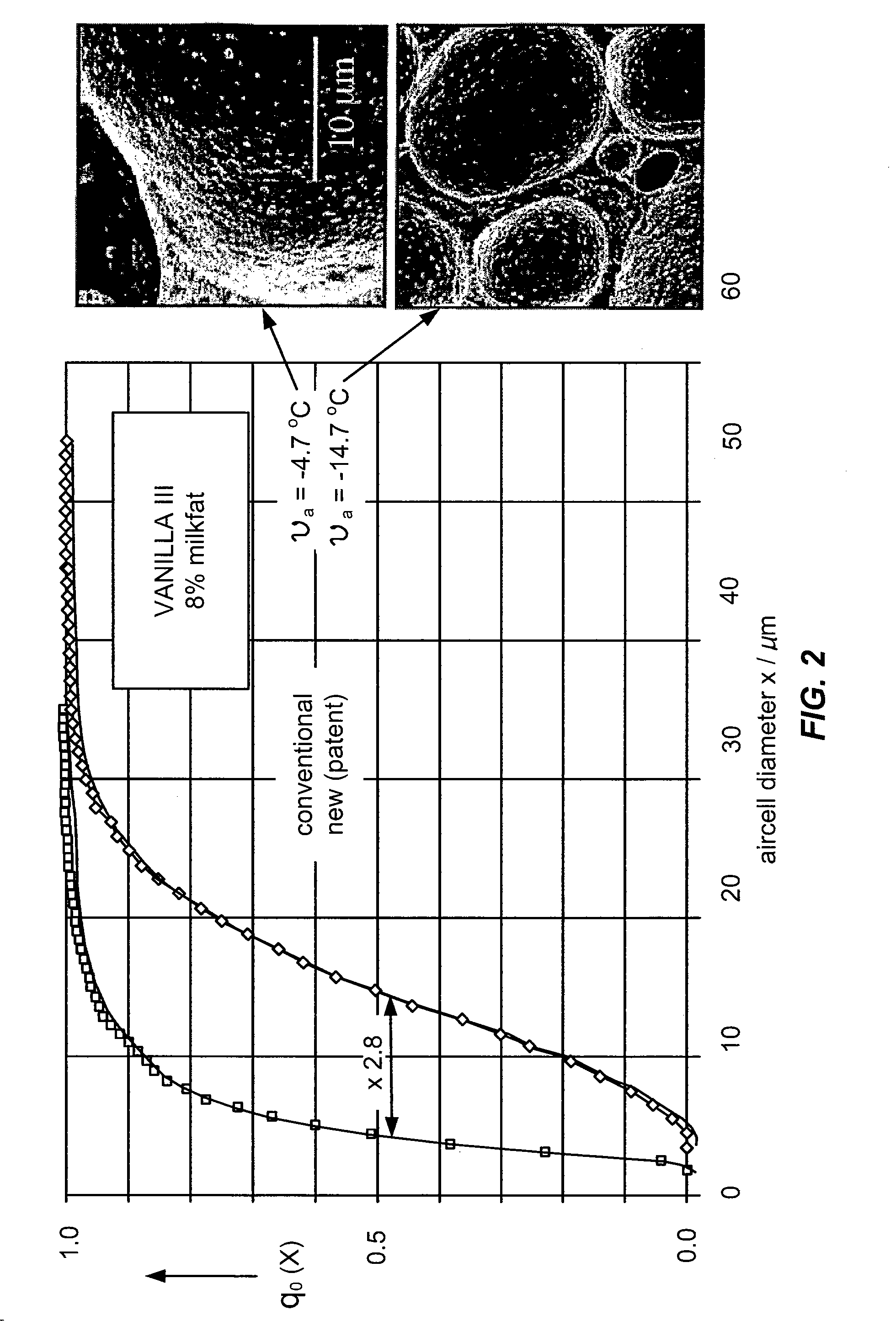

[0046] In micro-structuring studies in accordance with the present invention, the influence of low temperature, low shear treatment at ice crystal fractions larger than 50-60% has been investigated for a conventional vanilla ice cream with total dry matter content of 38% including 8% of milk fat and compared with conventionally treated / manufactured ice cream.

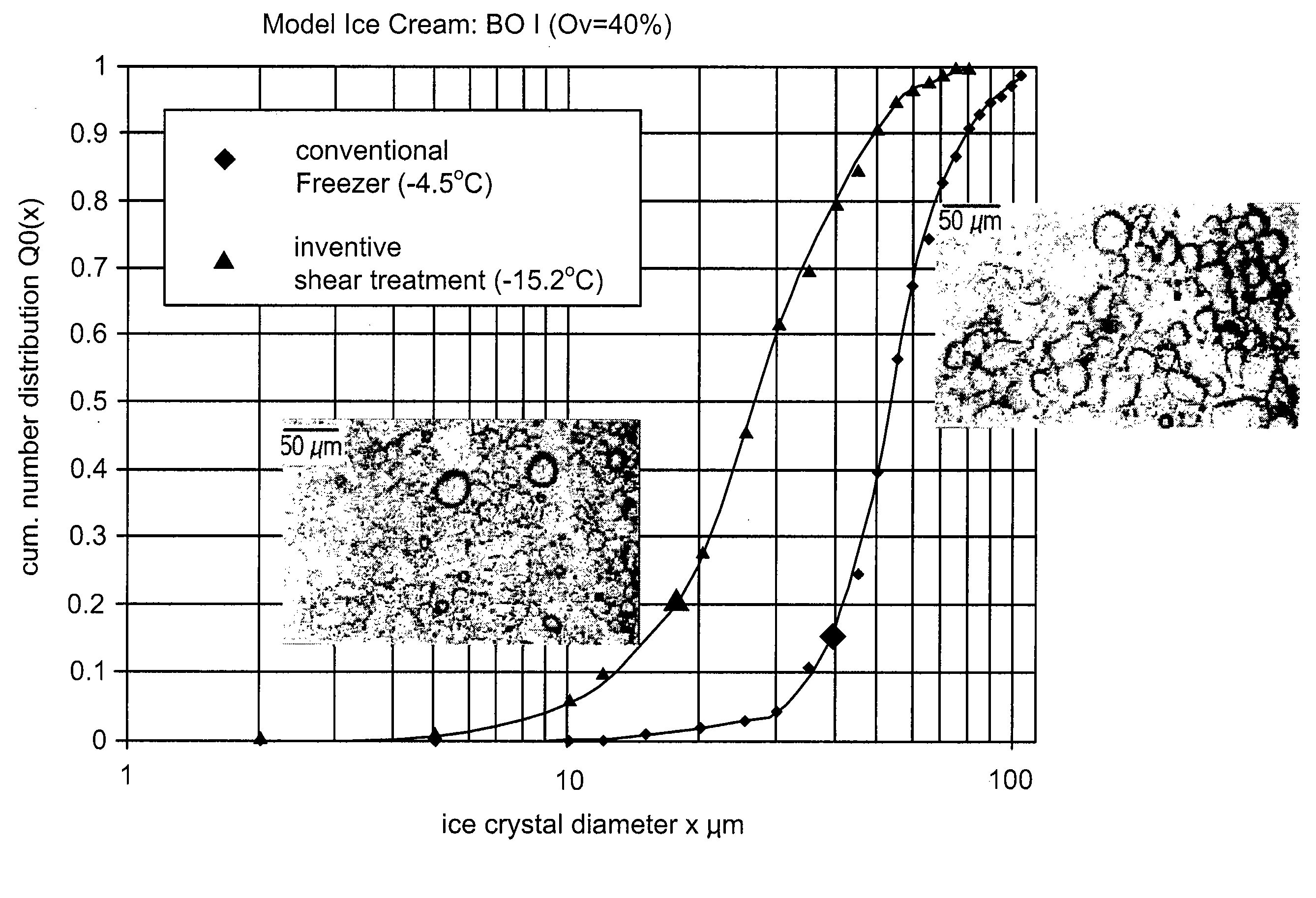

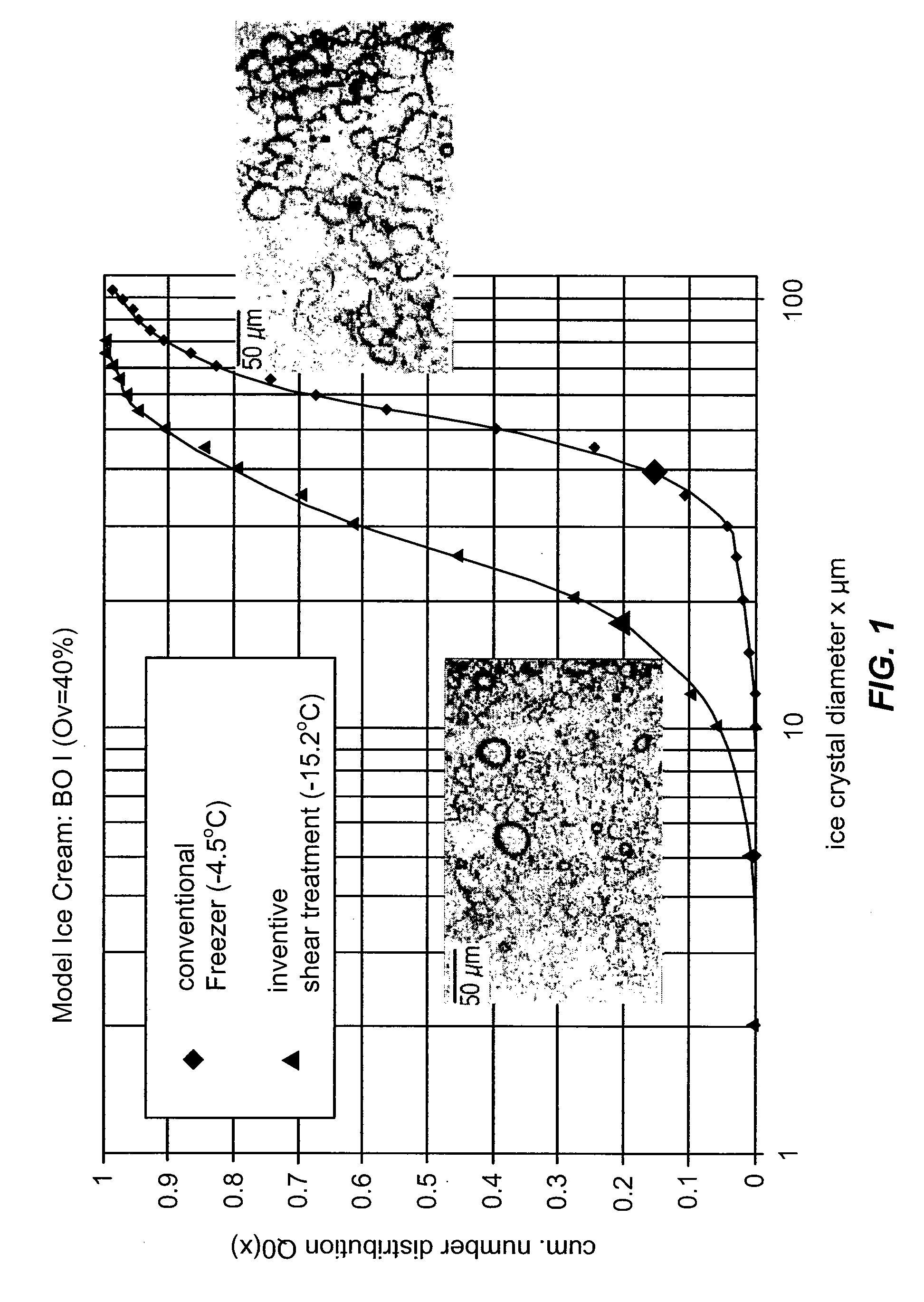

[0047] For this ice cream system it was shown that the mean ice crystal size in the freshly produced ice cream by low temperature, low shear treatment was reduced by the factor of 2-3 compared to a conventionally freezered (scraped surface heat exchanger) and hardened ice cream of the same recipe. The related size distribution functions of the ice crystals are given in FIG. 1.

[0048] Air cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com