Sheated-element glow plug having a particularly embedded contact element

a contact element and glow plug technology, applied in the direction of mechanical equipment, machines/engines, light and heating equipment, etc., can solve the problems of high manufacturing complexity and cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

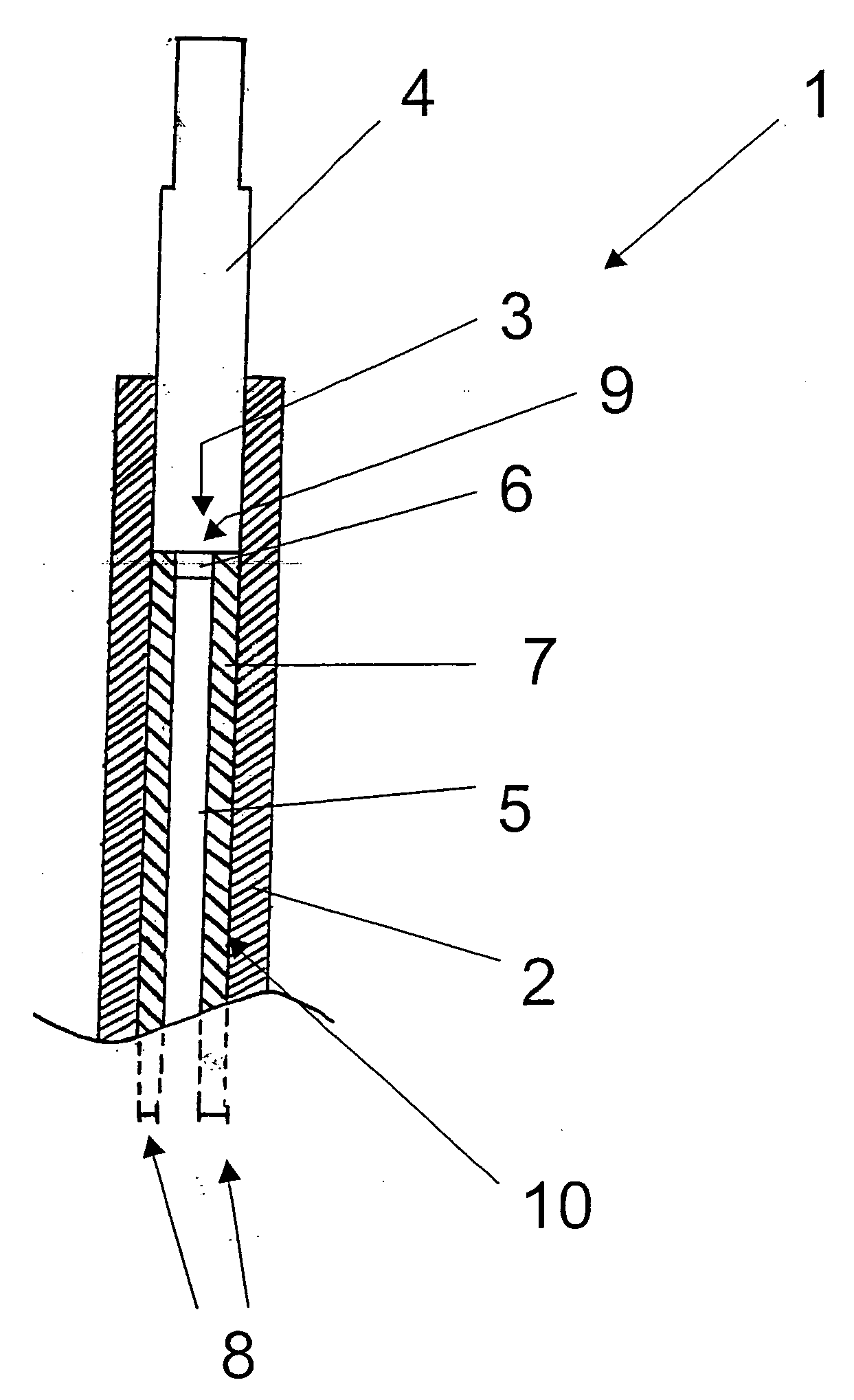

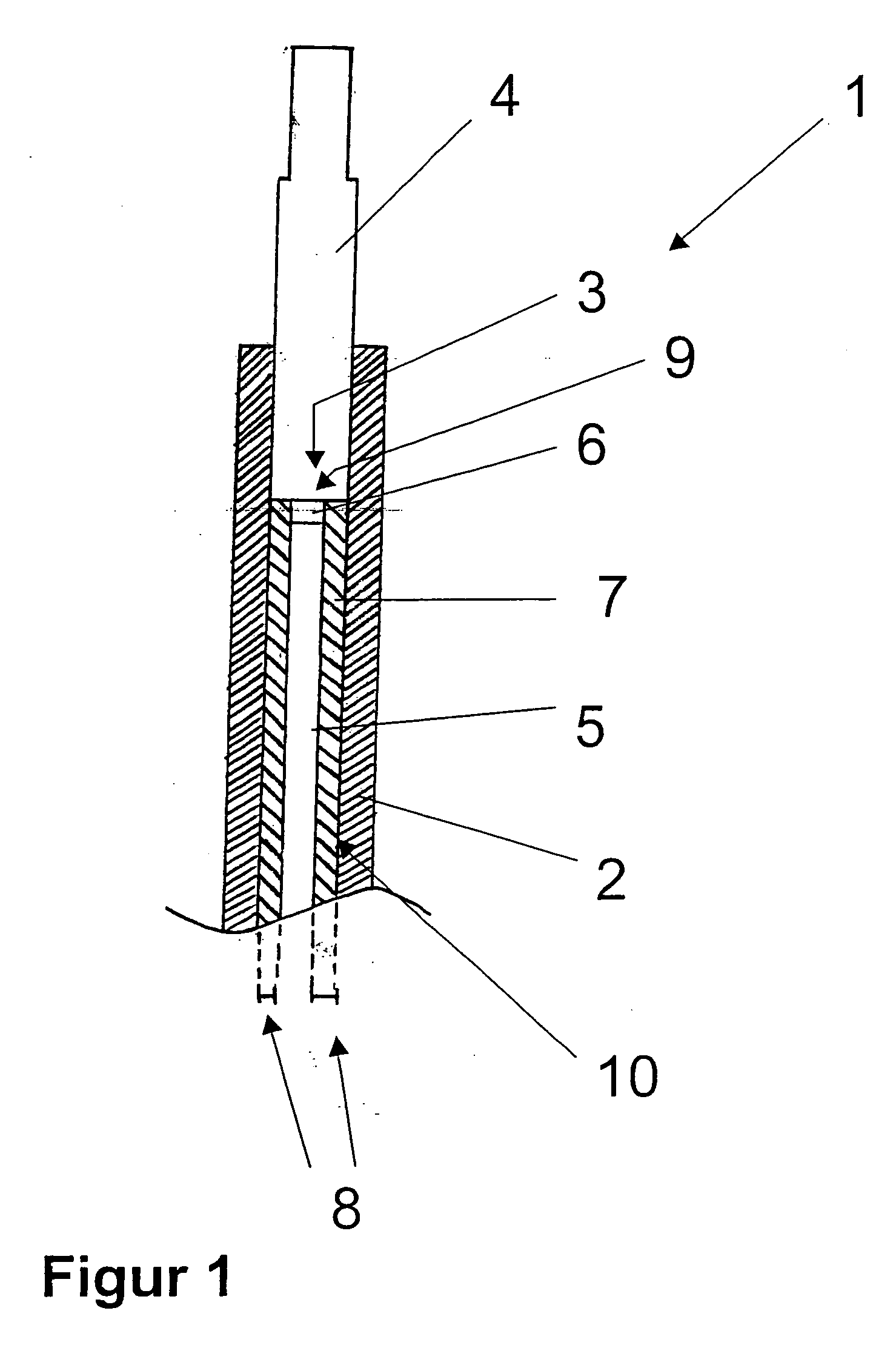

[0015] The parts of a sheathed-element glow plug 1 on which the present invention is based are shown in FIG. 1. This sheathed-element glow plug 1 is made up of a plug housing 2 and a connection area 3 of a sheathed-element heater 4, which is not shown in greater detail.

[0016] A terminal pin 5 is provided within housing 2. In order to produce the electrical contact between terminal pin 5 and connection area 3 of the heater, a contact element 6 is provided between these two elements. This contact element is preferably elastic. A contact element 6 of this type may be, for example, a graphite tablet.

[0017] In order to secure contact element 6 and insulate the contact element and terminal pin 5 from housing 2, according to the present invention, a plastic sleeve 7 is inserted into housing 2, terminal pin 4 being situated within the plastic sleeve. This plastic sleeve 7 having a thin wall 8 may be produced simply and cost-effectively.

[0018] A recess 9 is provided in connection area 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com