Loop type thermo siphon, stirling cooling chamber, and cooling apparatus

a technology of thermosyphon and cooling chamber, which is applied in the direction of domestic cooling apparatus, indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of improving heat radiation performance limit, and achieve the effect of reliably circulating coolant and high performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

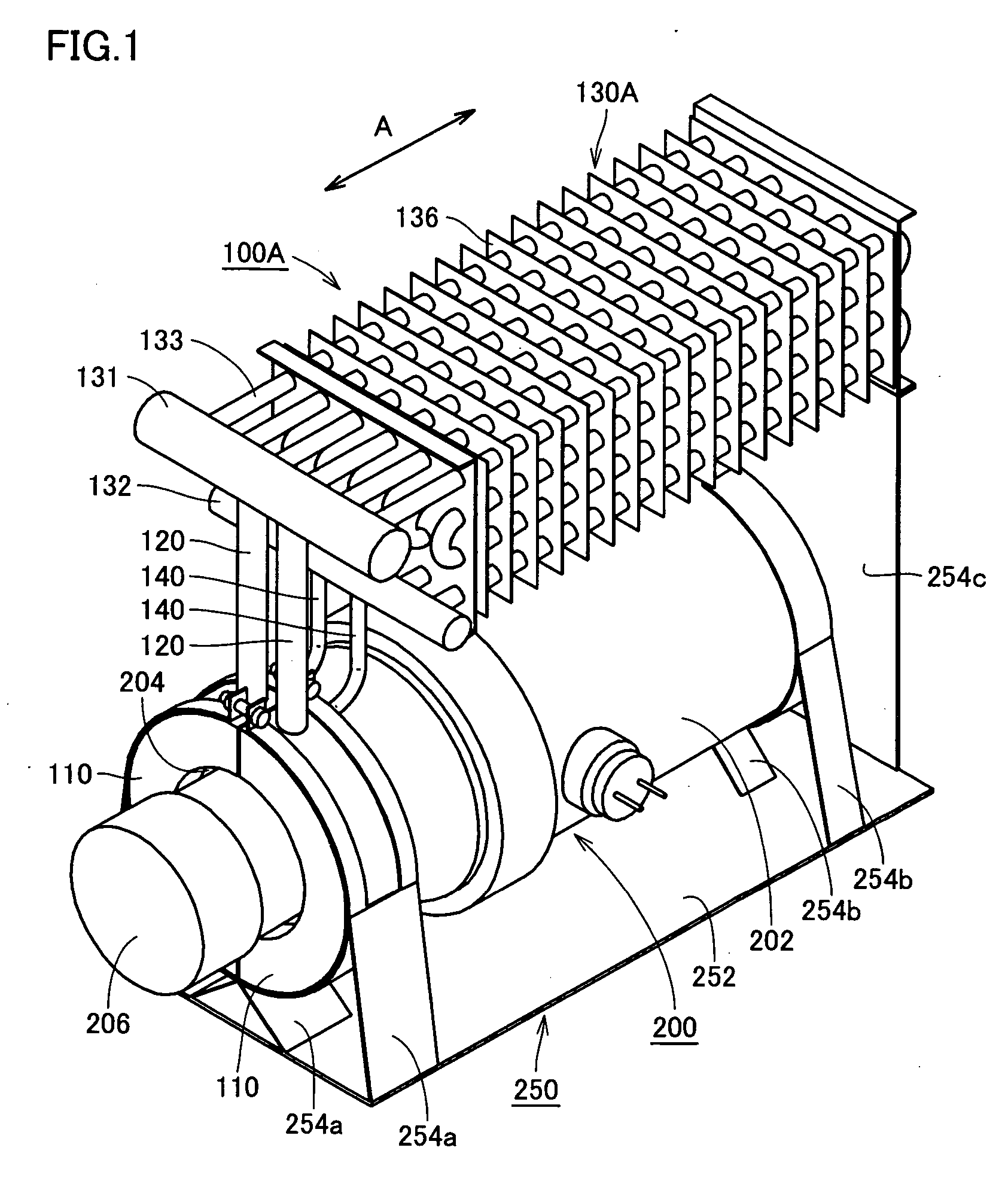

[0073] Initially reference will be made to FIG. 1 to describe a loop thermosyphon in the present embodiment and a structure of a Stirling refrigerating machine installed with the loop thermosyphon attached thereto.

[0074] As shown in the figure, a Stirling refrigerating machine 200 is placed on a supporting platform 250 and supported by supports 254a, 254b provided on platform 250 at a bottom plate 252. Furthermore, a loop thermosyphon 100A is also placed on platform 250 and supported thereon by support 254a, 254c provided at a bottom plate 252. Stirling refrigerating machine 200 and loop thermosyphon 100A supported by platform 250 are disposed in a casing of prescribed equipment (e.g., a refrigerator). Note that platform 250 has bottom plate 252 parallel to a bottom surface of the casing of the equipment.

[0075] Stirling refrigerating machine 200 is structured and operates, as described hereinafter.

[0076] As shown in FIG. 1, Stirling refrigerating machine 200 includes a pressure c...

second embodiment

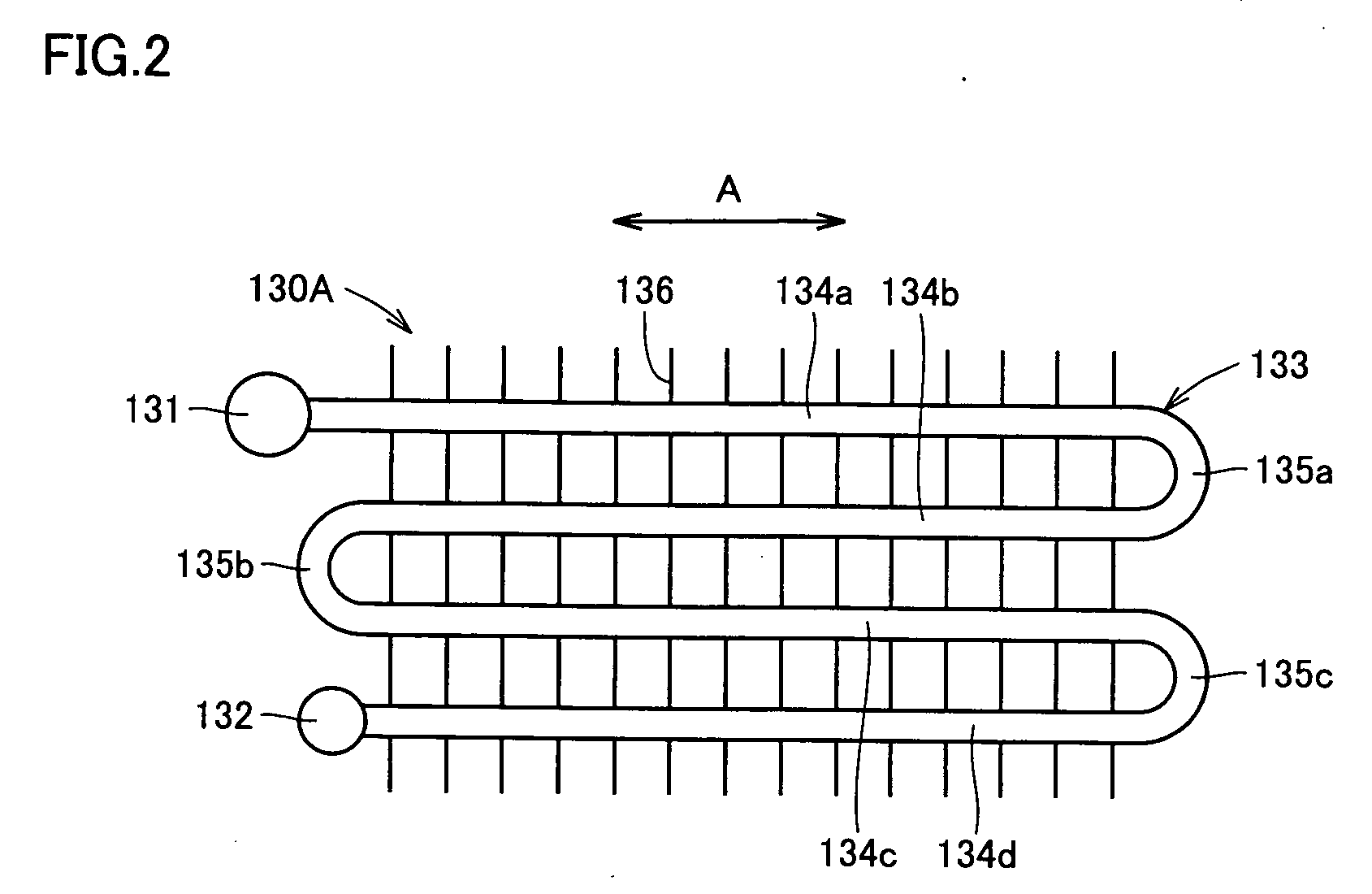

[0105] The present embodiment provides a loop thermosyphon 100B also utilized as a heat transfer system associated with a heated portion of a Stirling refrigerating machine, similarly as described in the first embodiment. Accordingly, the components similar to those of the first embodiment are shown in the figures with identical reference characters.

[0106] As shown in FIGS. 6A and 6B, the present embodiment provides loop thermosyphon 100B with a condenser 130B similar to condenser 130A of loop thermosyphon 100A described in the first embodiment. More specifically, condenser 130B is unitized as an assembly formed of header pipe 131 associated with a feed pipe, header pipe 132 associated with a return pipe, the plurality of aligned pipes 133 connecting header pipes 131 and 132 together, and a radiating fin 136 provided in contact with aligned pipes 133.

[0107] Aligned pipe 133 has a linear portion extending in a first direction (indicated in the figure by an arrow A), and header pipe...

third embodiment

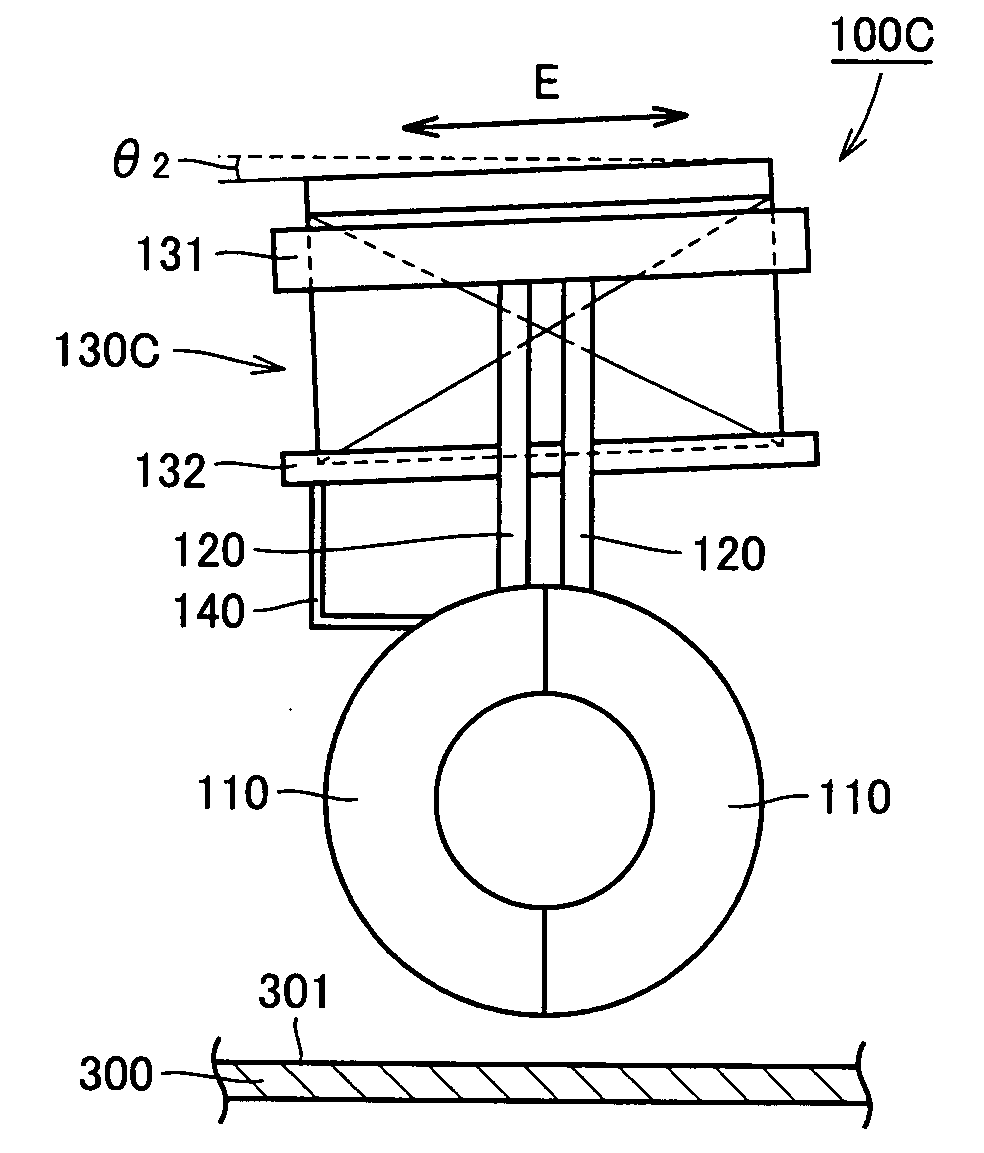

[0115] The present embodiment provides a loop thermosyphon 100C also utilized as a heat transfer system associated with a heated portion of a Stirling refrigerating machine, similarly as described in the first or second embodiment. Accordingly, the components similar to those of the first or second embodiment are shown in the figures with identical reference characters.

[0116] As shown in FIGS. 7A and 7B, the present embodiment provides loop thermosyphon 100C with a condenser 130C similar to condensers 130A and 130B of loop thermosyphons 100A and 1001B described in the first and second embodiments. More specifically, condenser 130C is unitized as an assembly formed of header pipe 131 associated with a feed pipe, header pipe 132 associated with a return pipe, the plurality of aligned pipes 133 connecting header pipes 131 and 132 together, and radiating fin 136 provided in contact with aligned pipes 133.

[0117] In the present embodiment condenser 130C is arranged to entirely incline b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com