Rack boot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

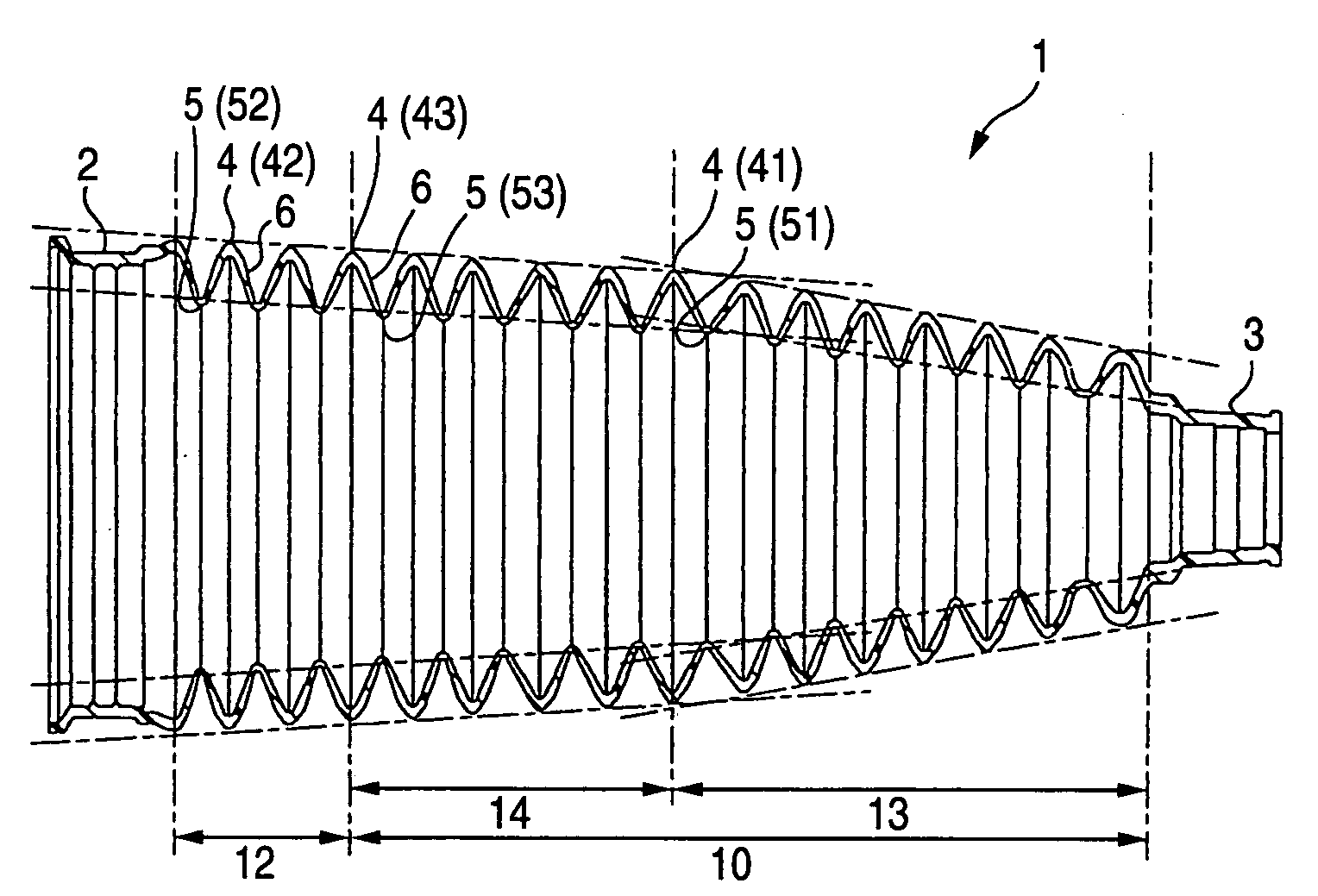

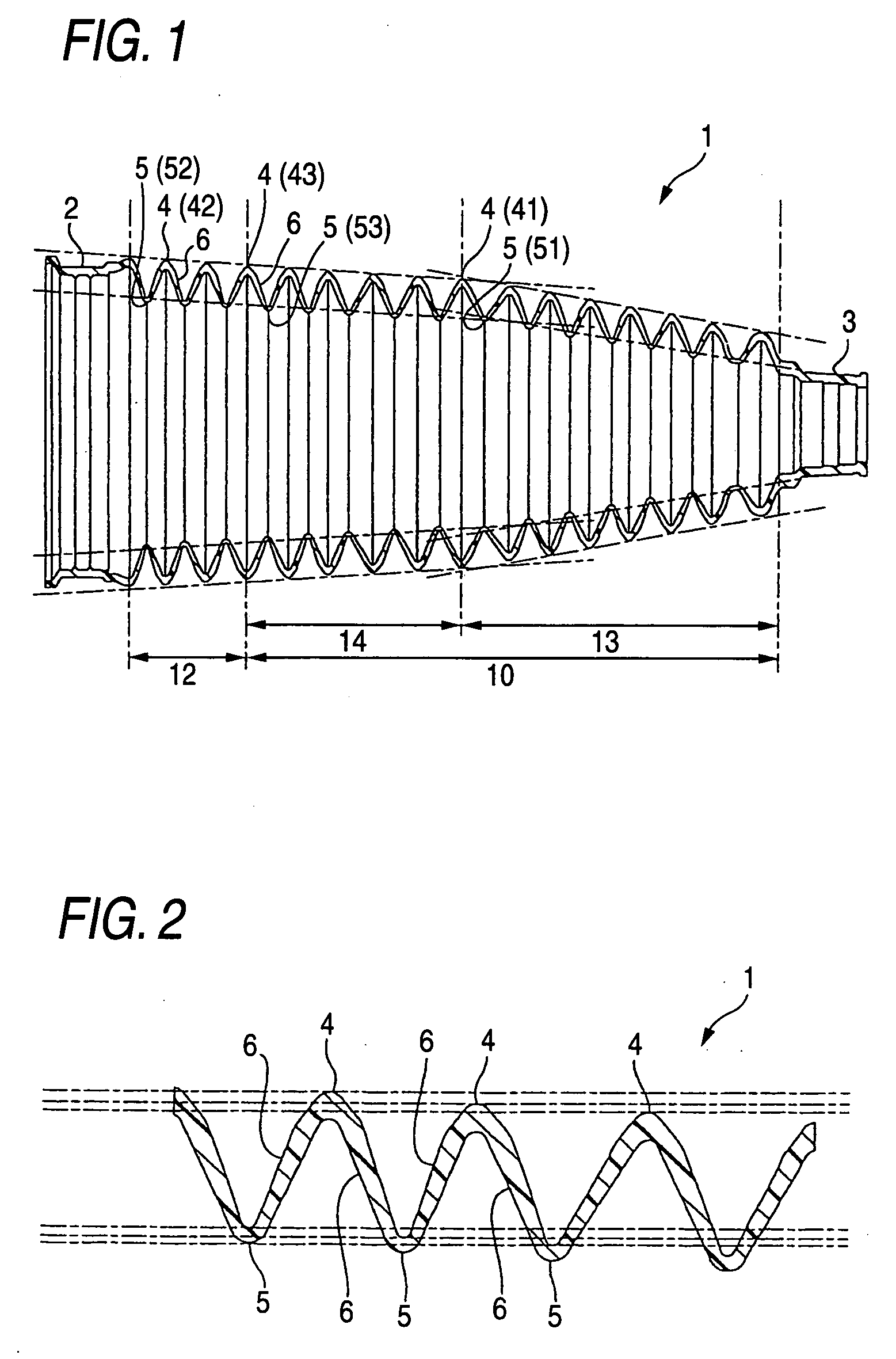

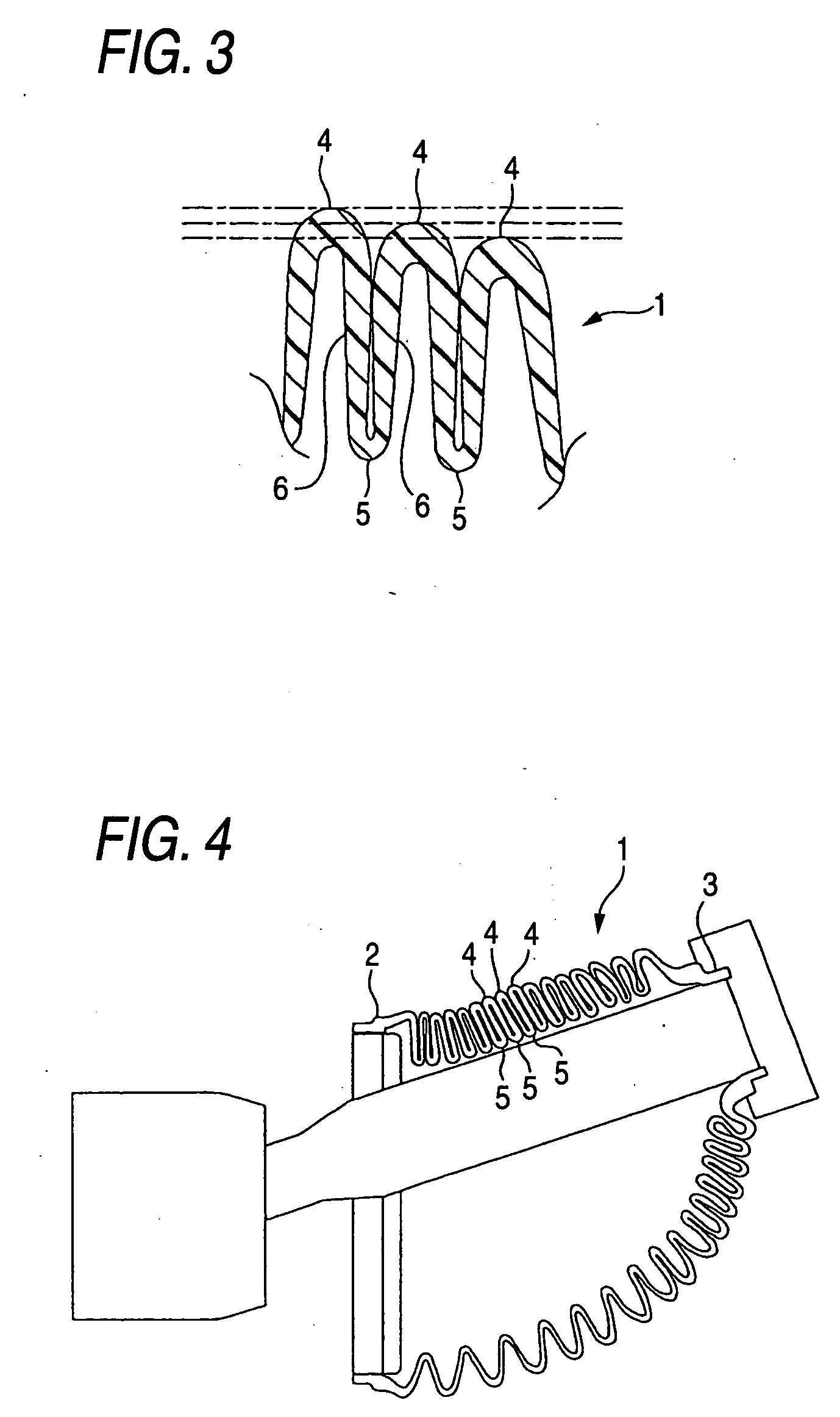

[0038] A rack boot of Embodiment 1 includes the configurations described under (1) to (4). An axially sectional view is shown in FIG. 1 which shows the rack boot of Embodiment 1, and an enlarged view of a main part of FIG. 1 is shown in FIG. 2. An explanatory view of the main part of the rack boot of Embodiment 1 is shown in FIG. 3 which shows exemplarily a state in which the rack boot is compression deformed in an axial direction thereof. An explanatory view is shown in FIG. 4 which shows exemplarily a state in which the rack boot of Embodiment 1 is compression deformed while swinging largely.

[0039] As shown in FIGS. 1 and 2, the resin boot of Embodiment 1 includes a bellows portion 1, a second cylindrical portion 2 and a first cylindrical portion 3. The bellows portion 1, the second cylindrical portion 2 and the first cylindrical portion 3 are formed integrally through blowmolding. The second cylindrical portion 2 is formed into a ring shape and is attached to a steering gearbox ...

embodiment 2

[0050] A rack boot of Embodiment 2 includes the configurations described under (2) to (4). An axially sectional view s shown in FIG. 5 which shows exemplarily the rack boot of Embodiment 2.

[0051] As shown in FIG. 5, the rack boot of Embodiment 2 includes a bellows portion 1, a second cylindrical portion 2 and a first cylindrical portion 3. The first cylindrical portion 3 and the second cylindrical portion 2 are the same as those of Embodiment 1. The bellows portion 1 is made up of a first bellows portion 10 and a second bellows portion 12. As with Embodiment 1, the first bellows portion 10 has a small diameter side bellows portion 13 and a large diameter side bellows portion 14. The small diameter side bellows portion 13 has a shape which is the same as that of Embodiment 1.

[0052] The large diameter side bellows portion 14 is formed into a tapered shape in which an outside diameter of ridge portions 4 is such that an outside diameter of the ridge portion 4 is made smaller than an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com