Radiator module for commercial motor vehicles

a technology for commercial motor vehicles and radiators, applied in the direction of superstructure subunits, stationary conduit assemblies, lighting and heating apparatus, etc., can solve the problems of increased height of radiator blocks, increased heat sinks, and inability to encroach on the vehicle, and achieve the effect of simple arrangemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

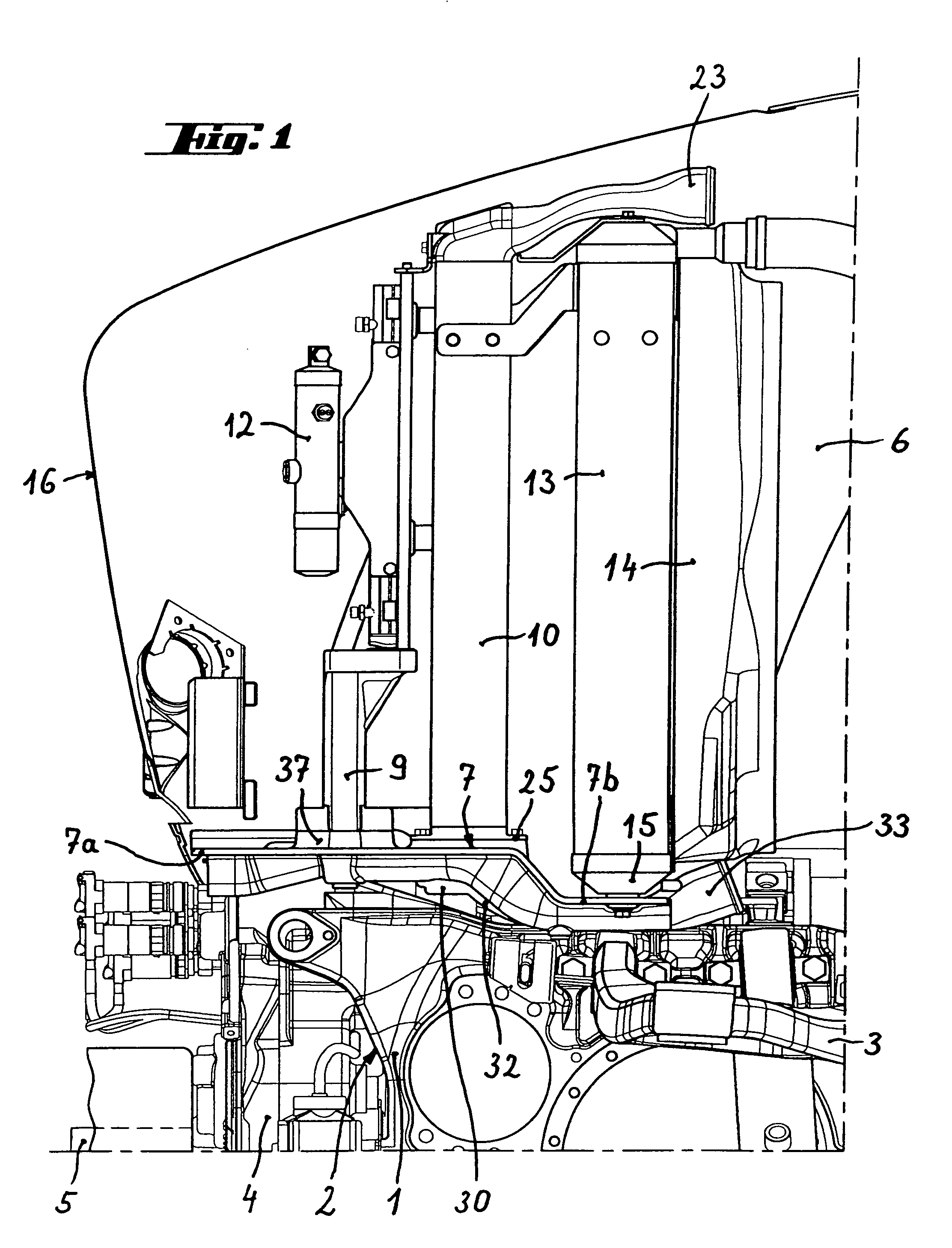

[0016] As is evident from FIG. 1, two laterally spaced side members 1, which are part of a front axle housing 2 extend fore and aft and are oriented substantially parallel to each other to form the chassis at the front end of an agricultural tractor. Only one of these side members 1 is visible in FIG. 1. An upper wishbone of a wheel suspension indicated with the reference numeral 3, which is linked to the side members 1, is also shown. In the front region of the front axle housing 2 a transmission casing 4, in which a variable transmission for driving a front power take-off shaft 5 is accommodated, is arranged between the side members 1. The rear part of the transmission casing 4 has its highest point roughly in the centre between the side members 1, which drops away towards the side members 1.

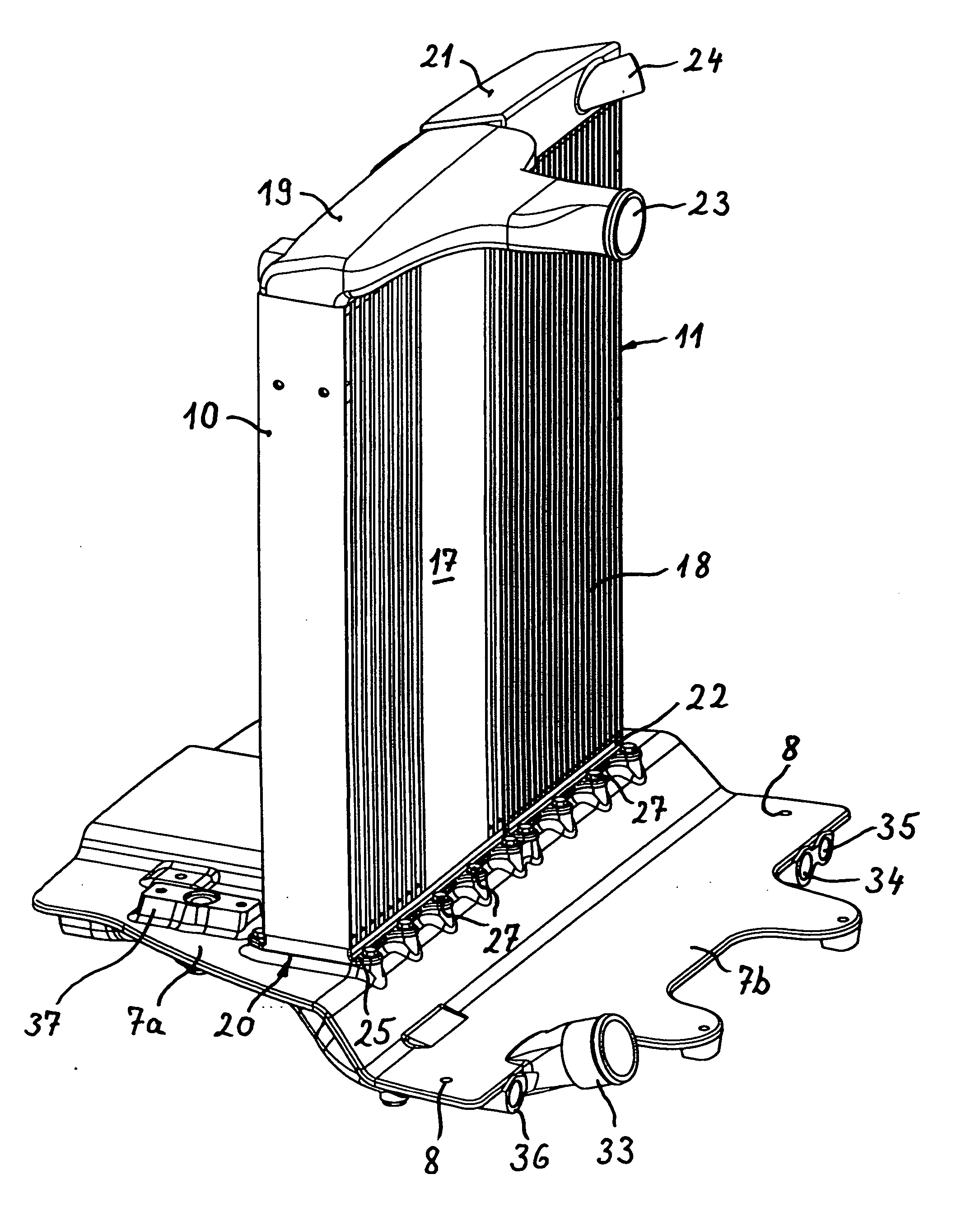

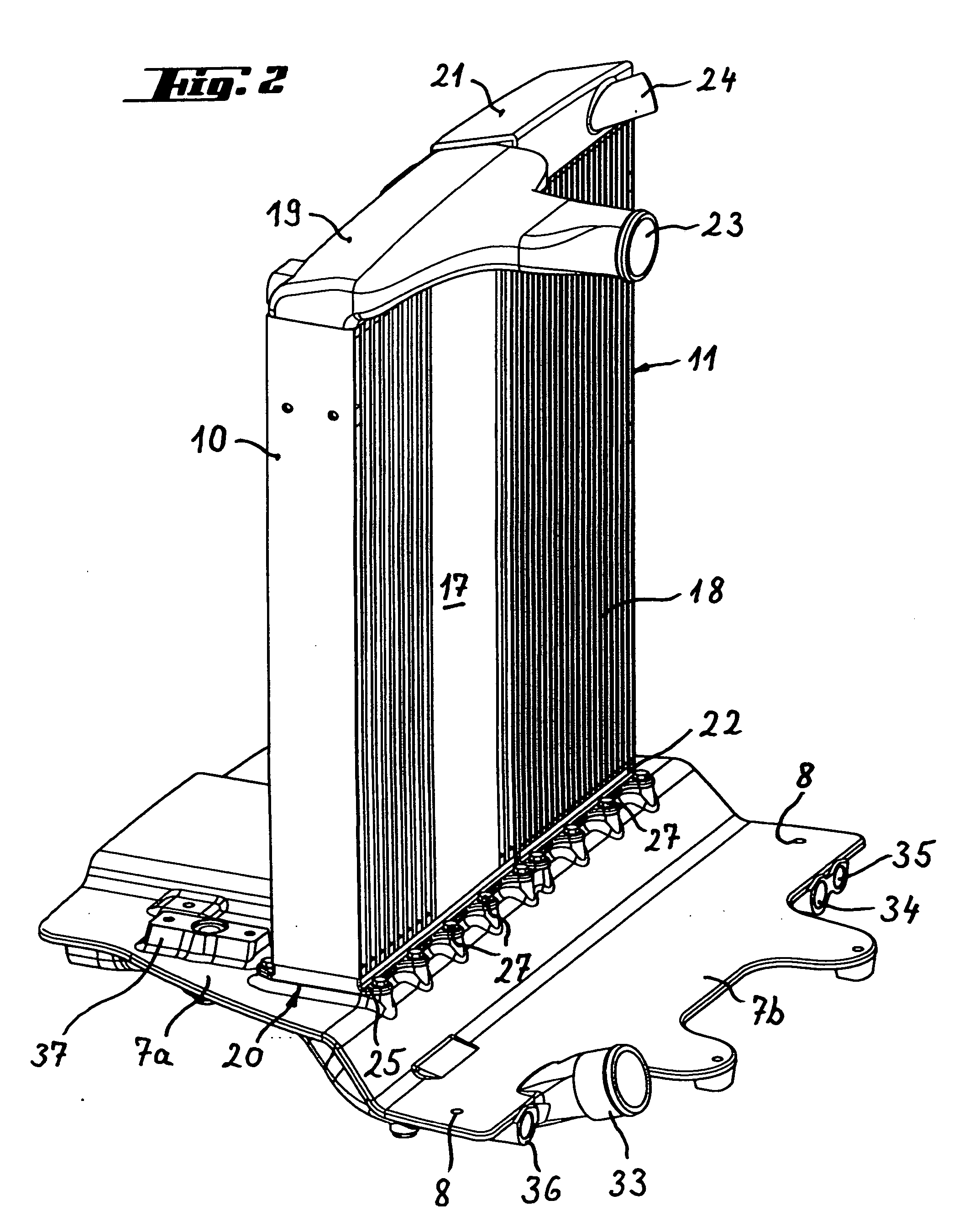

[0017] Likewise in the front area of the front axle housing 2 a radiator module 6 sits on the side members 1. The radiator module 6 consists of a support plate 7 as well as several coolant ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com