Golf spike

a golf spike and spike technology, applied in the field of golf spikes, can solve the problems of rigidity of the conventional tees, the inability to precisely set the ball elevation, and the inability to ensure the consistent distance from the ground, so as to increase the surface for advertising and more stability of the ball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

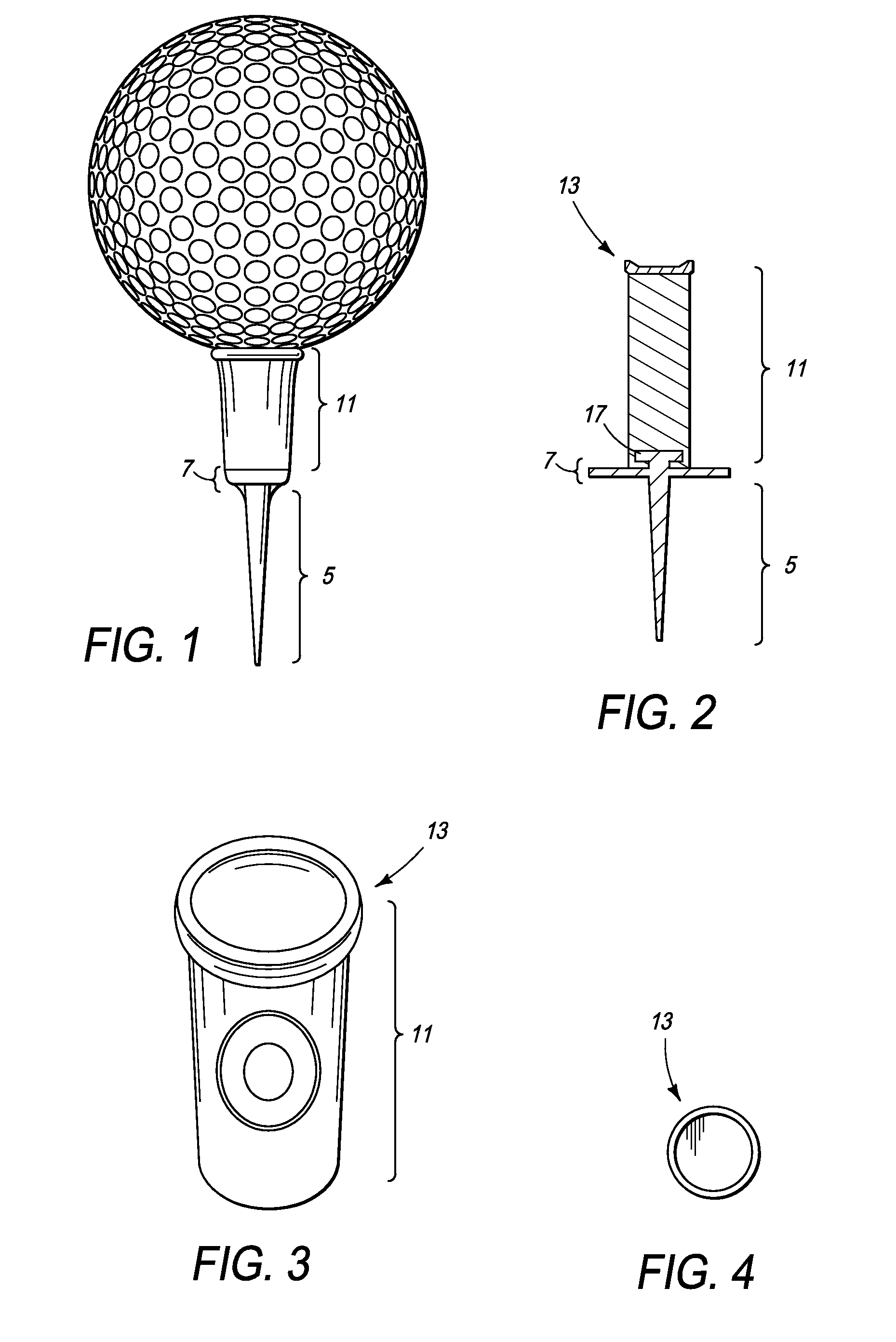

Image

Examples

Embodiment Construction

[0019] After reading this description it will become apparent to one skilled in the art how to implement the invention in various alternative embodiments and alternative applications. However, although various embodiments of the present invention will be described herein, it is understood that these embodiments are presented by way of example only, and not limitation. As such, this detailed description of various alternative embodiments should not be construed to limit the scope or breadth of the present invention as set forth in the appended claims.

[0020] The present invention discloses a golf tee which securely holds golf balls and secondarily allow ample space for advertising media. This tee is designed with flexible top structure which in one embodiment can be formed from rubber, silicone, plastic, neoprene, foam, or any other composite pliable or flexible materials. The flexible top structure is made with a material which has memory so that it rebounds to it's original shape w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com