Joint for operatively coupling a contoured inner compression member and an inner guide channel member for medical device delivery systems

a compression member and contoured technology, applied in the field of joint assembly for operative coupling an inner compression member and an inner guide channel member, can solve the problems of increasing requiring some form of mechanical fastener, and confusing the goal of minimizing the distal end profil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

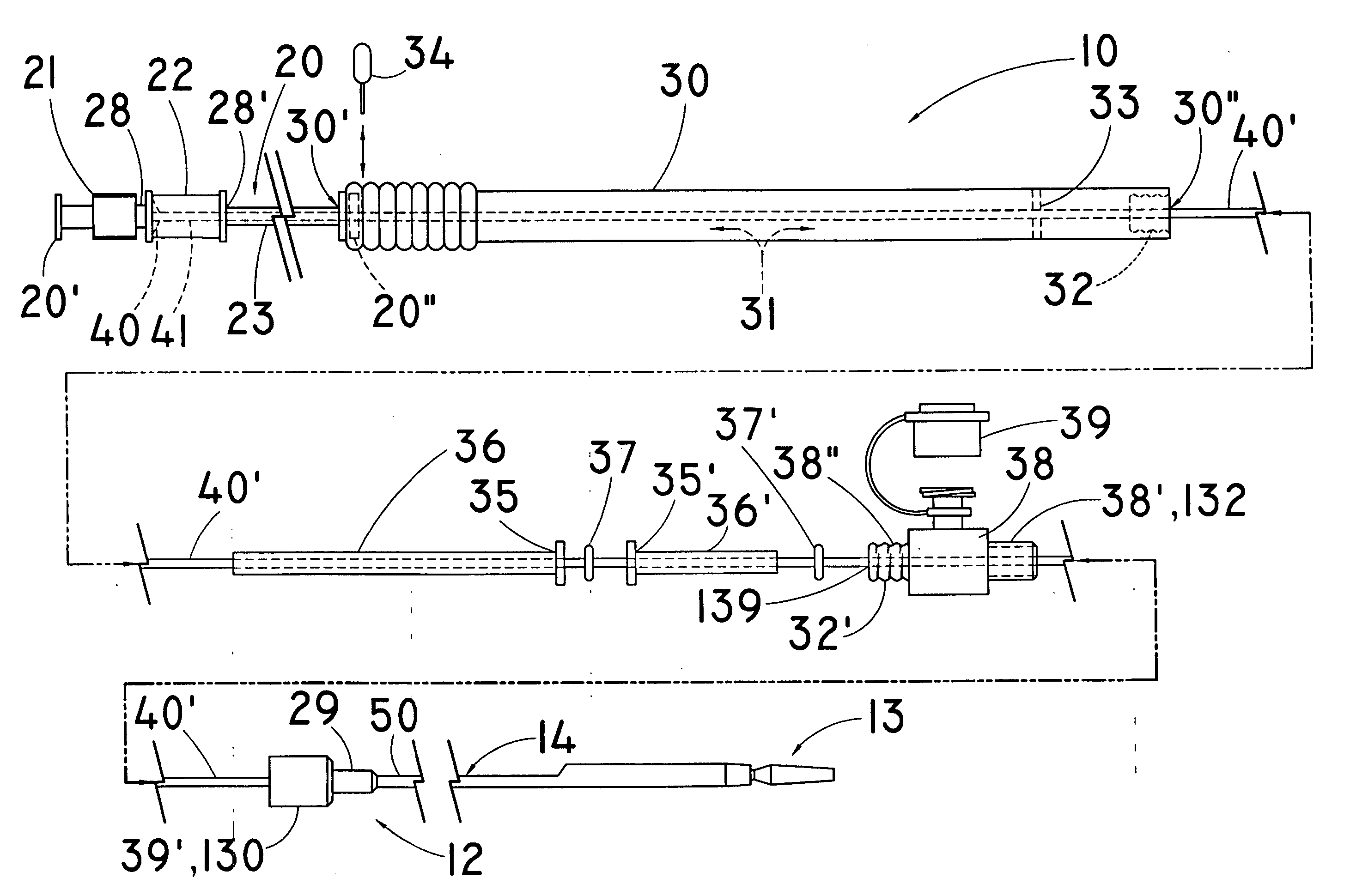

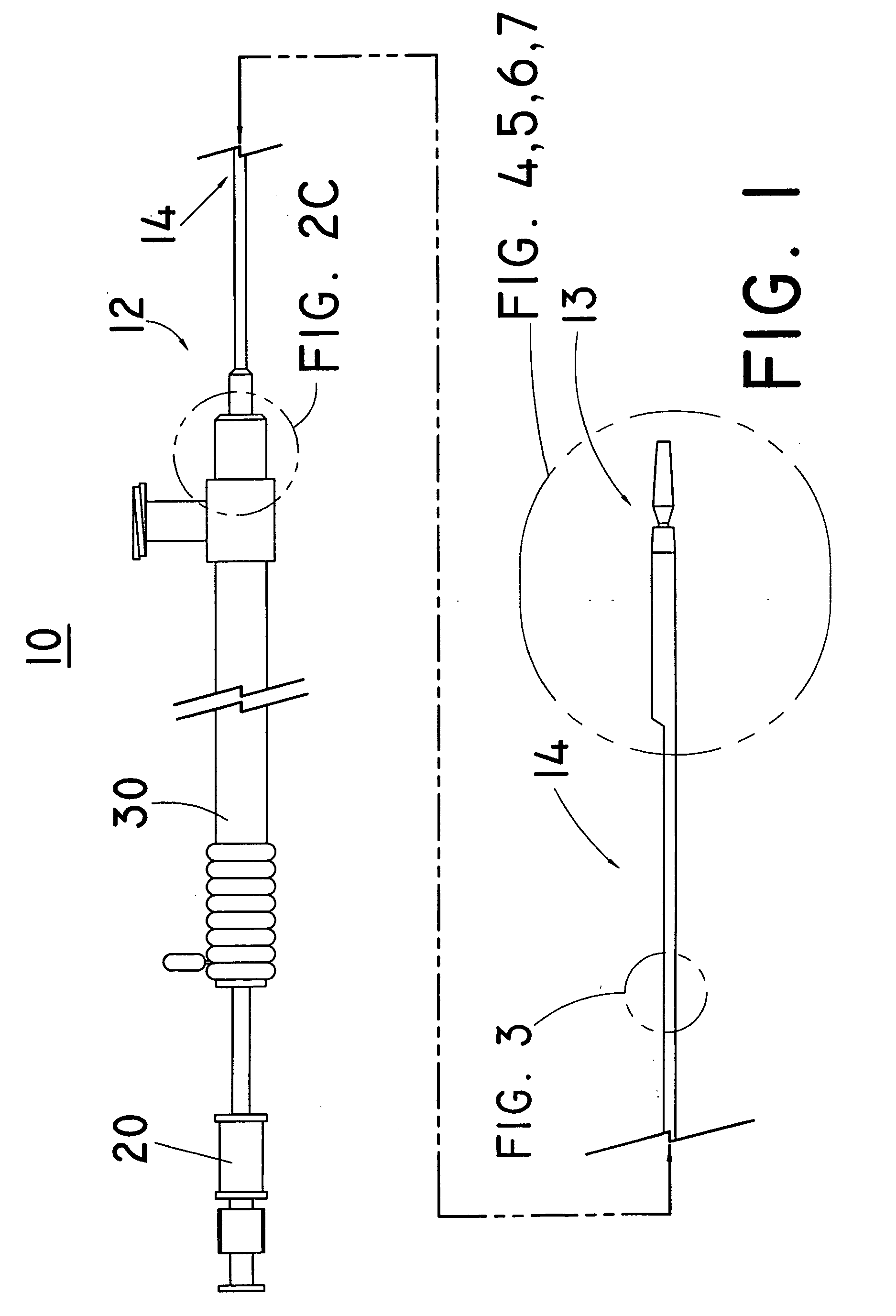

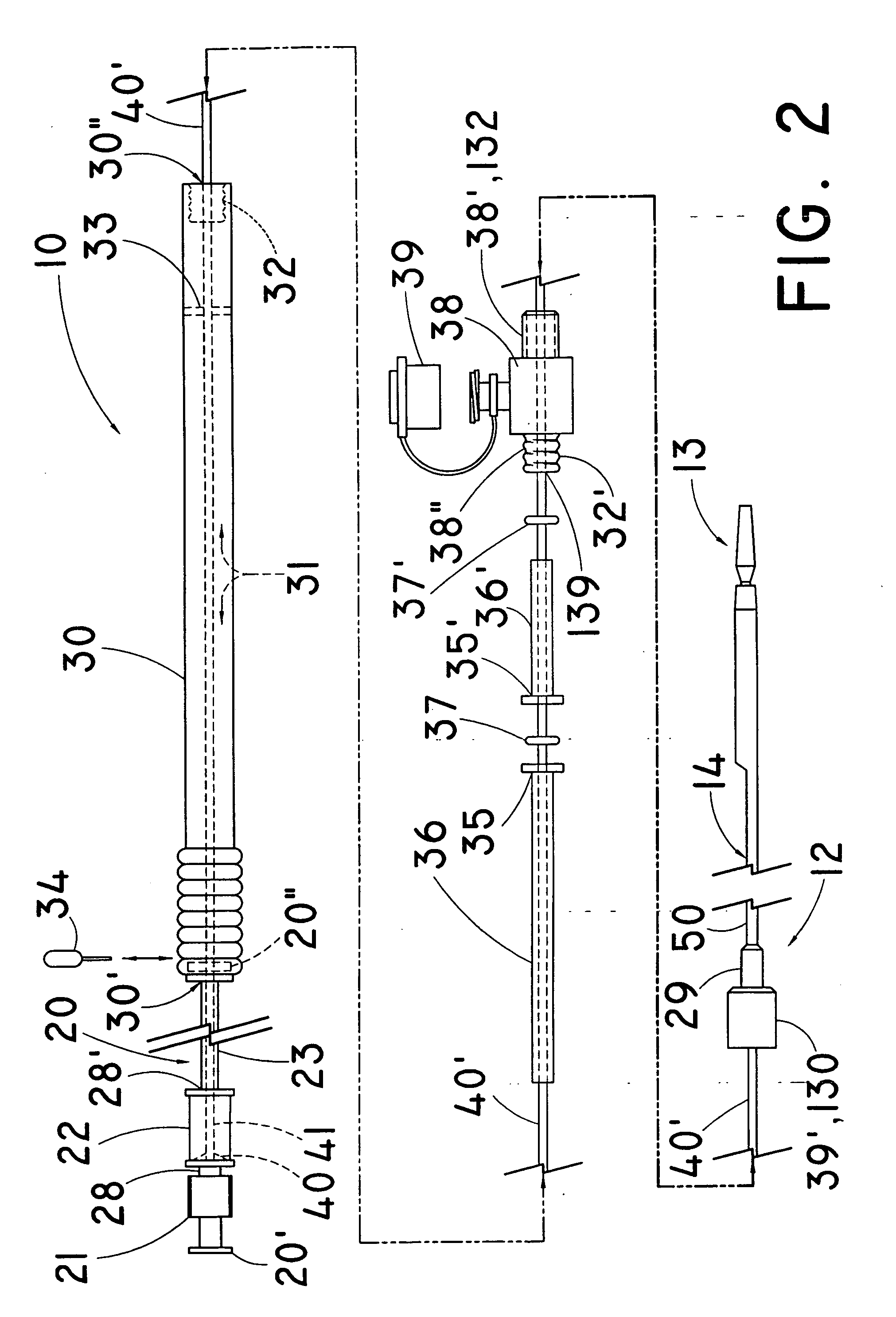

[0052] The present invention relates to medical devices, and in particular to an inner guide channel member assembly and to a joint assembly comprising a securing body operatively coupled to the inner guide channel member and an inner compression member joint assembly an inner compression member and also operatively coupling a low-profiled inner compression member for use in rapid insertion medical device delivery systems (e.g., “rapid insertion” catheters) configured for deploying expandable metallic, polymeric, and plastic devices or non-expanding metallic, polymeric, and plastic devices, which devices may include, by way of example and not by way of limitation, stents, prosthetic valve devices, and other implantable articles at selected locations inside a patient's body. For conciseness and ease of description of the embodiments of the invention, the term “stent” and its variations shall refer individually and collectively (without limiting the invention) to all self-expanding, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shrinkage | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com