Compositions and methods of remediation devices with nanostructured sorbent

a carbonaceous nanostructure and sorbent technology, applied in sustainable biological treatment, biological water/sewage treatment, water cleaning, etc., can solve the problems of loss of capacity where activated charcoal is not retained, not all compounds are retained by activated charcoal, and relatively limited sorption capacity of activated charcoal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

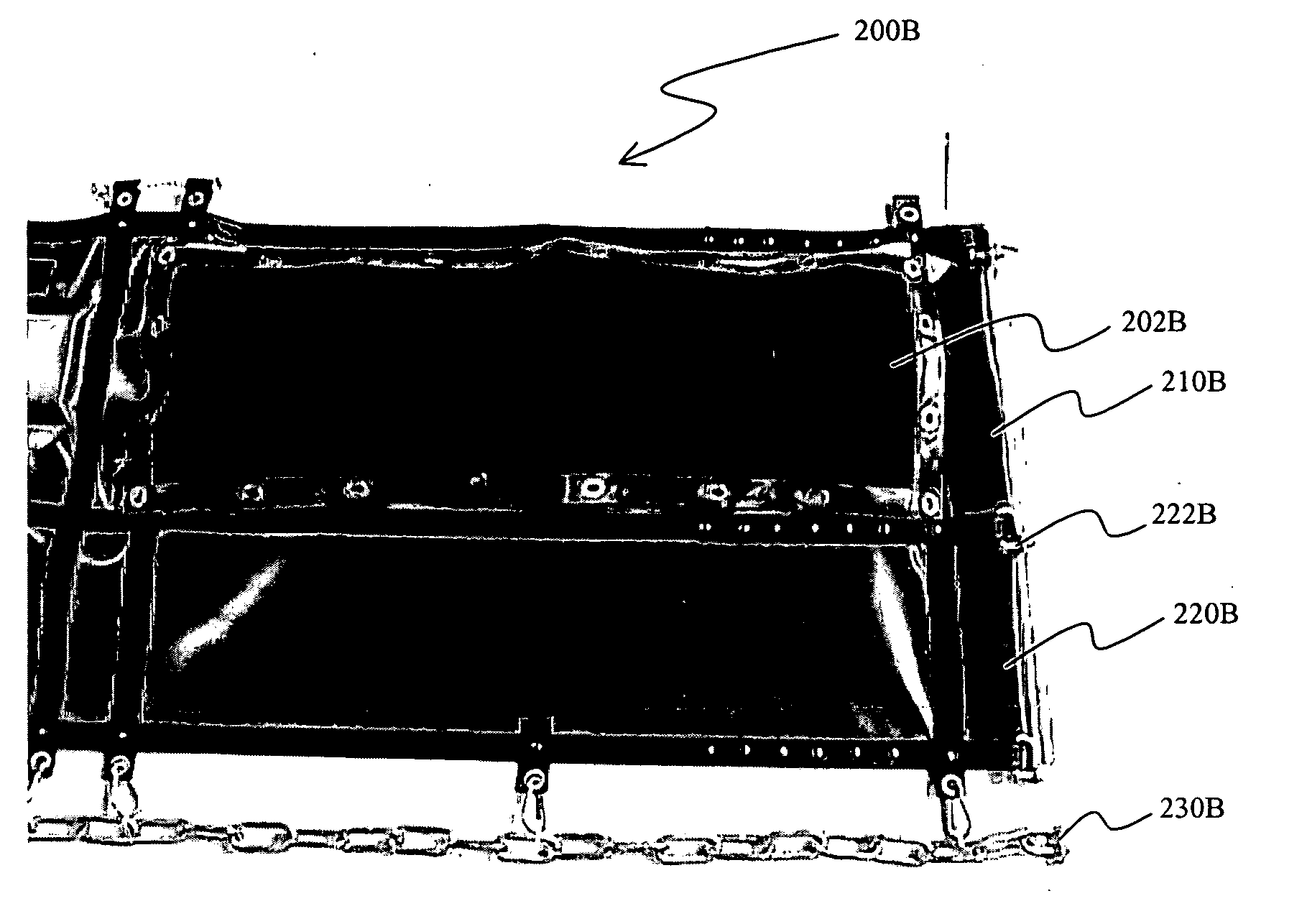

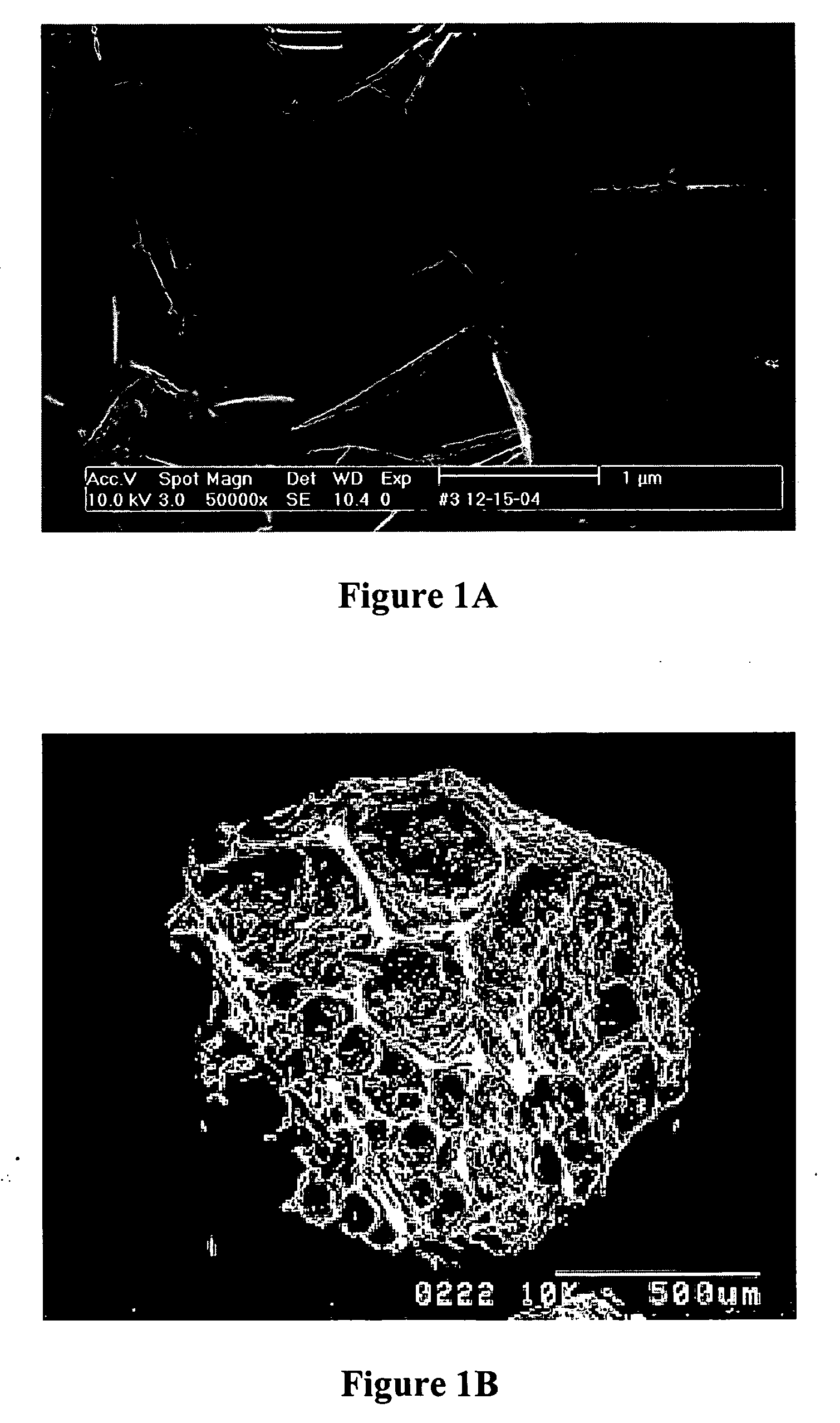

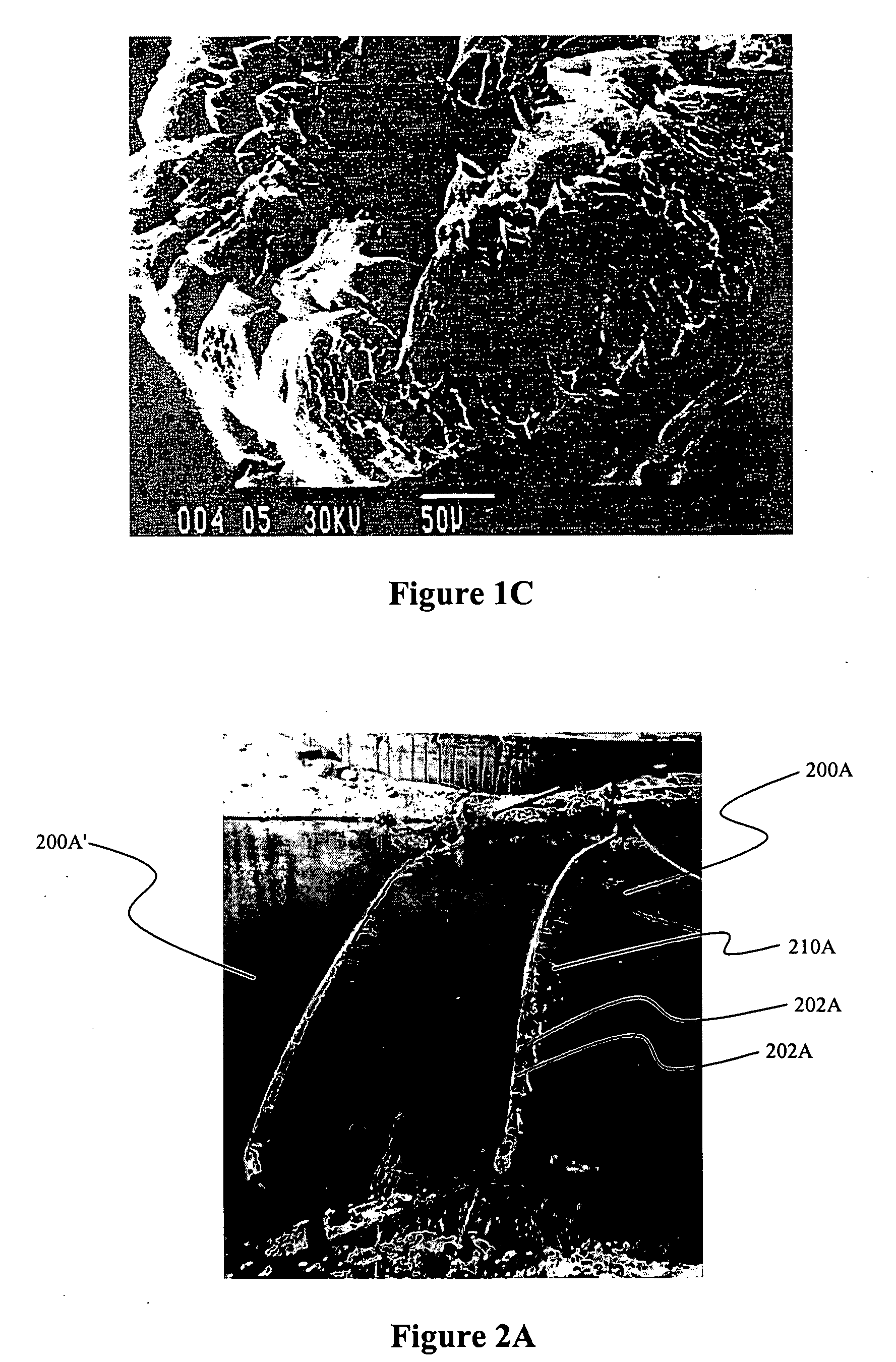

[0016] The inventors have discovered that nanostructured materials, and especially non-porous carbonaceous materials, and most preferably graphene-containing materials can be employed as highly active sorbents for numerous contaminants. It is especially preferred that the material is employed in the separation of optionally substituted hydrocarbons from an aqueous medium, and most preferably while the material is present in a boom.

[0017] Among other advantages, it should be particularly appreciated that adsorption of various hydrocarbons in and / or on aqueous media is highly effective due to the substantially completely hydrophobic nature of the carbonaceous material over even extended periods of time. Viewed from another perspective, while heretofore known carbonaceous adsorbents become waterlogged after a relatively short time (most typically due to the porous nature of such known materials), the carbonaceous materials according to the inventive subject matter can remain in / on an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nanoscale particle size | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com