Artificial cardiac pump

a technology of artificial heart pump and rotor, which is applied in the direction of prosthesis, liquid fuel engine, therapy, etc., can solve the problems of mechanical loss and damae, both sides are worn down and burned, and the rotor cannot be rotated smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

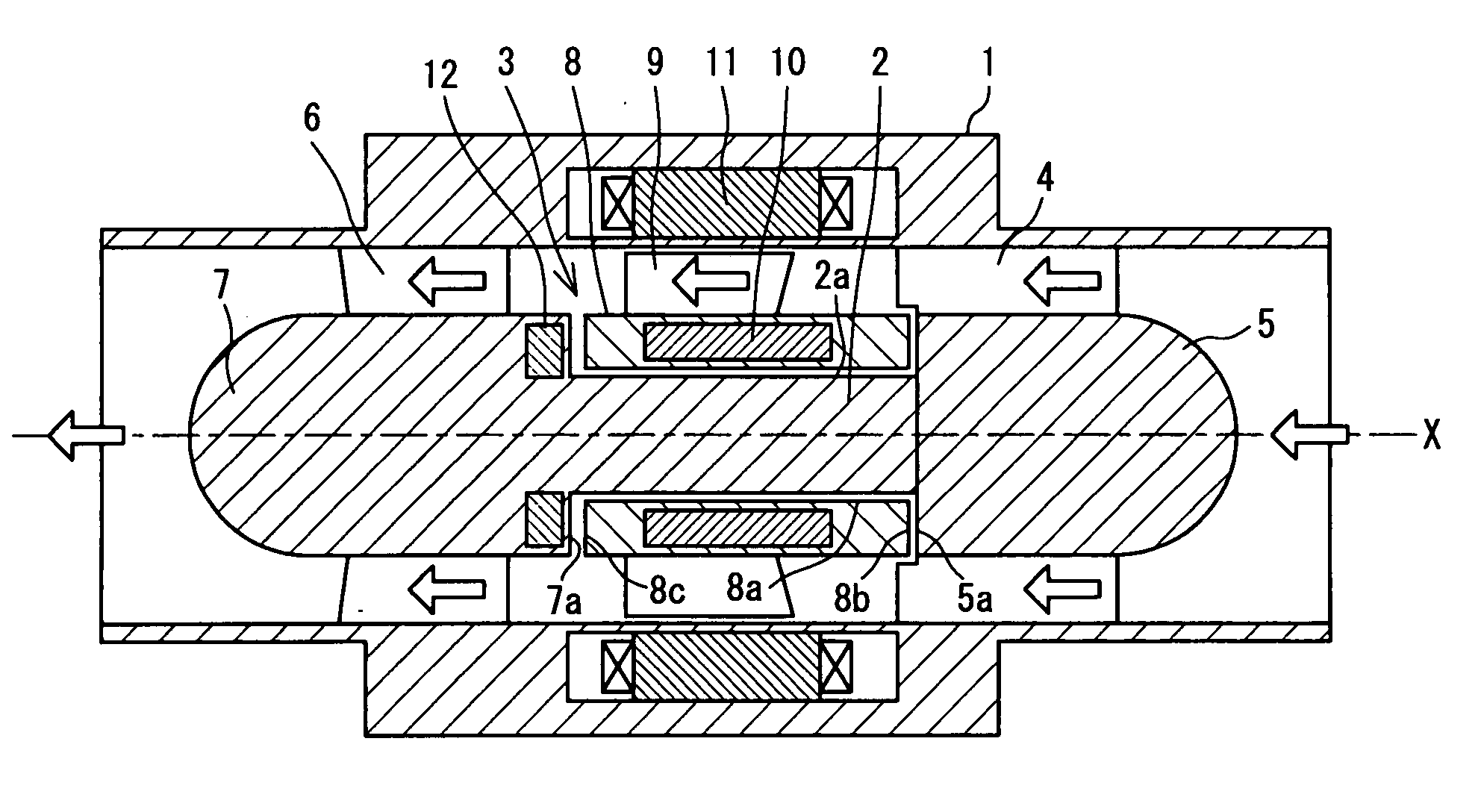

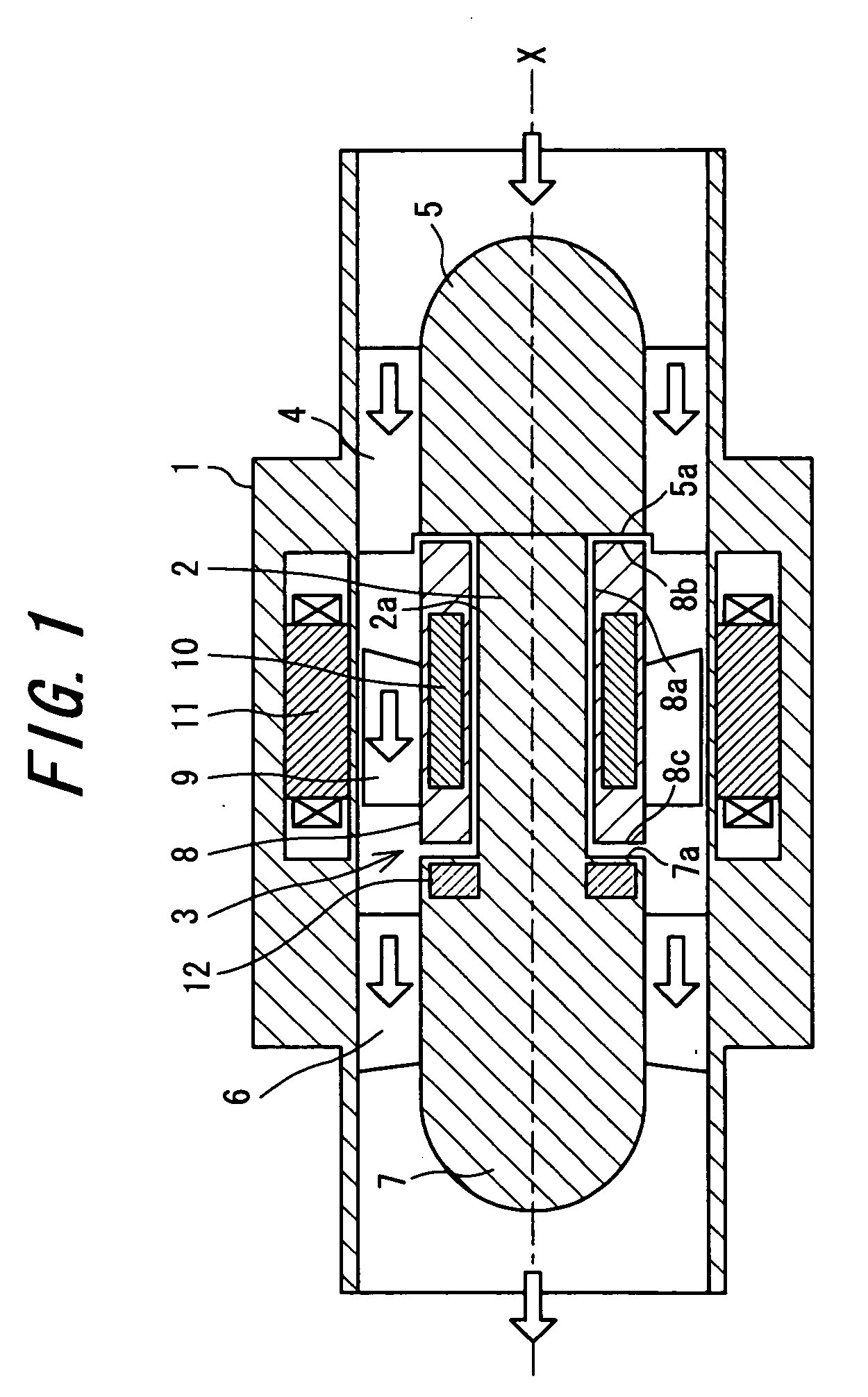

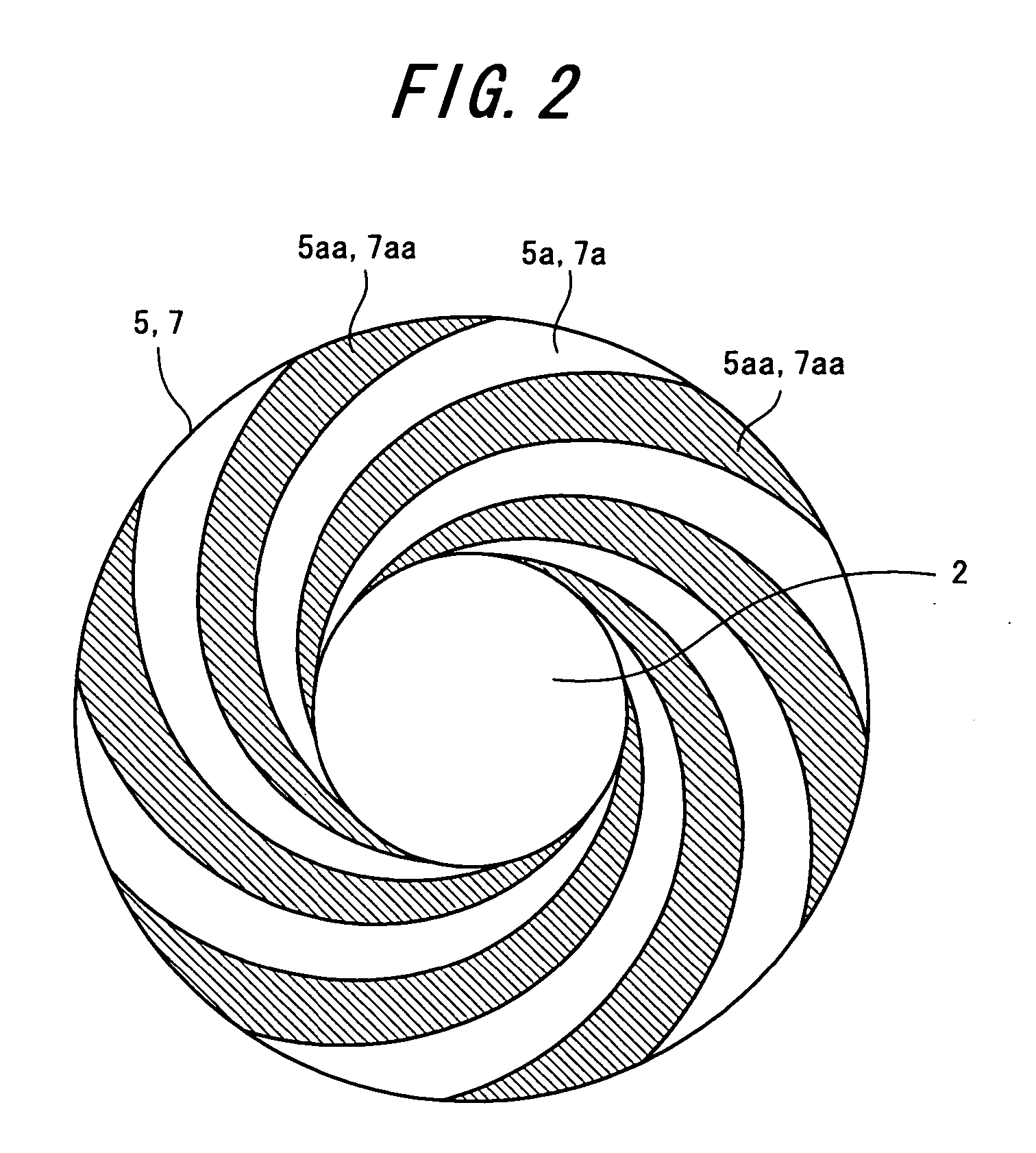

[0035] An embodiment of an artificial cardiac pump according to the present invention will be described with reference to the accompanying drawings. FIG. 1 shows a vertical cross sectional view of an embodiment of an artificial cardiac pump according to the present invention. FIG. 2 shows a plan view of a rear end surface of a front side fixed body and a front end surface of a rear side fixed body for showing thrust hydrodynamic grooves in its artificial cardiac pump. In the drawings, the same named components indicates the same numerals, respectively. Therefore, the description thereof is omitted.

[0036] As shown in FIG. 1, the embodiment of the artificial cardiac pump according to the present invention mainly comprises a cylindrical housing 1, a fixed axial body 2 as a central axis X in the housing, a rotor 3 that is an impeller rotatively supported in the housing with respect to the axial body 2 and a driving mechanism for rotating the rotor 3. By rotating the rotor 3, blood is t...

second embodiment

[0050] In the next, the second embodiment of the artificial cardiac pump according to the present invention will be described with reference to the drawings. FIG. 4 shows a cross sectional view for showing a structure of the second embodiment of the artificial cardiac pump according to the present invention. The embodiment is one of variations modified from the first embodiment as described above, wherein the same named components is numbered with the same reference numbers in the first embodiment of the artificial cardiac pump, respectively. The explanation thereof is omitted.

[0051] As shown in the drawings, the second embodiment of the artificial cardiac pump comprises a permanent magnet 13 as the first magnet and a permanent magnet 14 as the second magnet instead of the magnetic body 12. The permanent magnet 13 is installed in the sleeve at which the permanent magnet 13 is confronting with a rear end surface 5a of a front side fixed body 5. The permanent magnet 14 is installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com